Feeling lost in a sea of interview questions? Landed that dream interview for Materials Planner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Materials Planner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

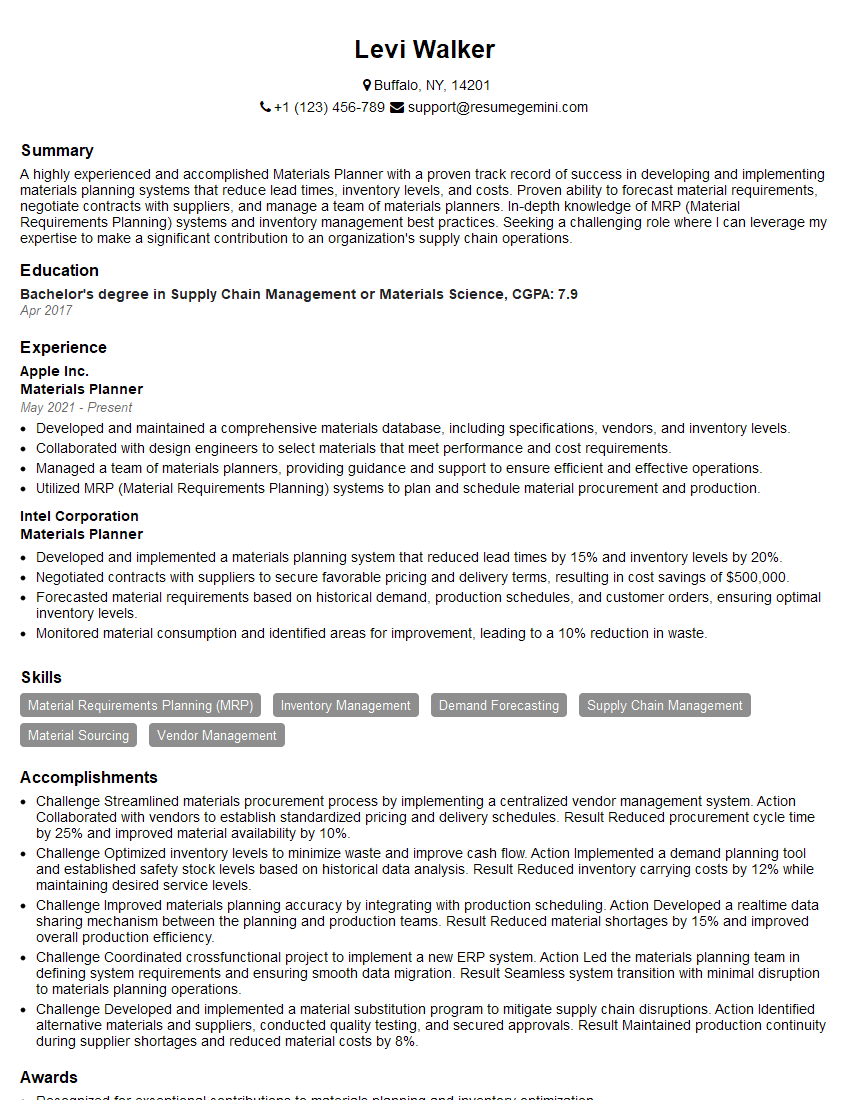

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Materials Planner

1. What are your key responsibilities as a Materials Planner?

- Develop and implement materials plans to meet production requirements.

- Manage materials inventory and ensure availability for production.

- Negotiate with suppliers and vendors for materials procurement.

- Monitor material prices and market trends.

- Collaborate with production and engineering teams to optimize material usage.

2. How do you ensure the quality of materials procured?

Supplier Evaluation

- Evaluate potential suppliers based on quality standards, capabilities, and reliability.

- Conduct site visits and audits to verify supplier operations.

Material Inspection

- Establish quality specifications and inspection criteria.

- Inspect incoming materials for compliance with specifications.

- Manage non-conforming materials and resolve supplier issues.

3. How do you optimize material inventory levels?

- Use inventory management techniques such as ABC analysis and reorder point calculation.

- Consider factors such as safety stock, lead times, and demand variability.

- Implement inventory optimization software to automate calculations and optimize inventory levels.

- Monitor inventory turnover ratios and adjust levels accordingly.

4. What inventory management strategies do you use?

- First-In, First-Out (FIFO) to prevent inventory obsolescence.

- Just-in-Time (JIT) to minimize inventory holding costs.

- Safety stock to buffer against supply chain disruptions.

- Consignment inventory to transfer inventory ownership to suppliers.

- Vendor-Managed Inventory (VMI) to optimize inventory levels and improve supplier collaboration.

5. How do you manage supplier relationships?

- Establish clear communication channels and regular touchpoints.

- Foster trust and transparency through open communication.

- Negotiate mutually beneficial contracts and pricing.

- Monitor supplier performance and identify areas for improvement.

- Provide feedback and support to improve supplier capabilities.

6. What materials management software do you have experience with?

- Material Resource Planning (MRP) systems

- Enterprise Resource Planning (ERP) systems

- Inventory Management Systems (IMS)

- Supplier Relationship Management (SRM) systems

- Data analytics and reporting tools

7. How do you handle material shortages or surpluses?

Shortages

- Identify alternative suppliers or substitute materials.

- Negotiate with current suppliers for expedited delivery.

- Explore air freight or other expedited shipping options.

- Communicate with production and engineering teams to adjust production plans.

Surpluses

- Identify opportunities to sell or donate excess materials.

- Negotiate with suppliers to return or adjust orders.

- Optimize inventory levels and reduce holding costs.

8. How do you ensure material availability during production peaks?

- Forecast and plan for increased demand based on historical data and production schedules.

- Build safety stock and maintain strong supplier relationships.

- Identify alternative suppliers or materials as backup plans.

- Collaborate with production teams to optimize production schedules and reduce demand spikes.

9. How do you track and measure material planning performance?

- Establish key performance indicators (KPIs) such as inventory turnover, fill rates, and lead times.

- Monitor and analyze these KPIs regularly.

- Identify improvement areas and implement measures to enhance material planning processes.

- Provide regular reports to management and stakeholders on material planning performance.

10. How do you stay updated on industry best practices in materials planning?

- Attend industry conferences and webinars.

- Read trade publications and research articles.

- Network with peers and attend professional development events.

- Seek opportunities to implement cutting-edge technologies and methodologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Materials Planner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Materials Planner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Materials Planner is responsible for planning and coordinating the procurement, storage, and distribution of materials for a company. They work closely with suppliers, vendors, and other departments within the company to ensure that materials are available when needed and at the lowest possible cost.

1. Plan and forecast material requirements

Materials Planners develop and maintain production schedules and forecasts, which they use to calculate the amount of materials that will be needed to meet production goals. They also consider factors such as lead times, supplier availability, and inventory levels when making their plans.

- Analyze historical data to determine future material requirements

- Develop and maintain production schedules and forecasts

2. Source and procure materials

Materials Planners are responsible for sourcing and procuring the materials that are needed for production. They work with suppliers and vendors to negotiate prices, delivery schedules, and payment terms.

- Identify and qualify suppliers

- Negotiate prices and delivery schedules

- Place and track orders

3. Manage inventory

Materials Planners are responsible for managing the company’s inventory of materials. They track inventory levels, identify slow-moving items, and develop strategies to reduce inventory costs.

- Track inventory levels

- Identify slow-moving items

- Develop strategies to reduce inventory costs

4. Distribute materials

Materials Planners are responsible for distributing materials to production departments. They work with production supervisors to determine when and where materials are needed.

- Develop and maintain distribution schedules

- Coordinate with production supervisors

- Track materials shipments

Interview Tips

Preparing for an interview for a Materials Planner position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, business goals, and the specific responsibilities of the Materials Planner role.

- Visit the company’s website

- Read articles about the company in trade publications

- Talk to people in your network who work at the company

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer interview questions

- Be specific and provide examples

- Quantify your accomplishments whenever possible

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Materials Planner. Be prepared to discuss your experience in planning and forecasting material requirements, sourcing and procuring materials, managing inventory, and distributing materials. You should also be able to talk about your skills in negotiation, problem-solving, and communication.

- Highlight your experience in relevant areas

- Quantify your accomplishments and provide examples

- Be prepared to discuss your skills and how they would benefit the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Materials Planner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!