Are you gearing up for an interview for a Materials Planner/Production Planner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Materials Planner/Production Planner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

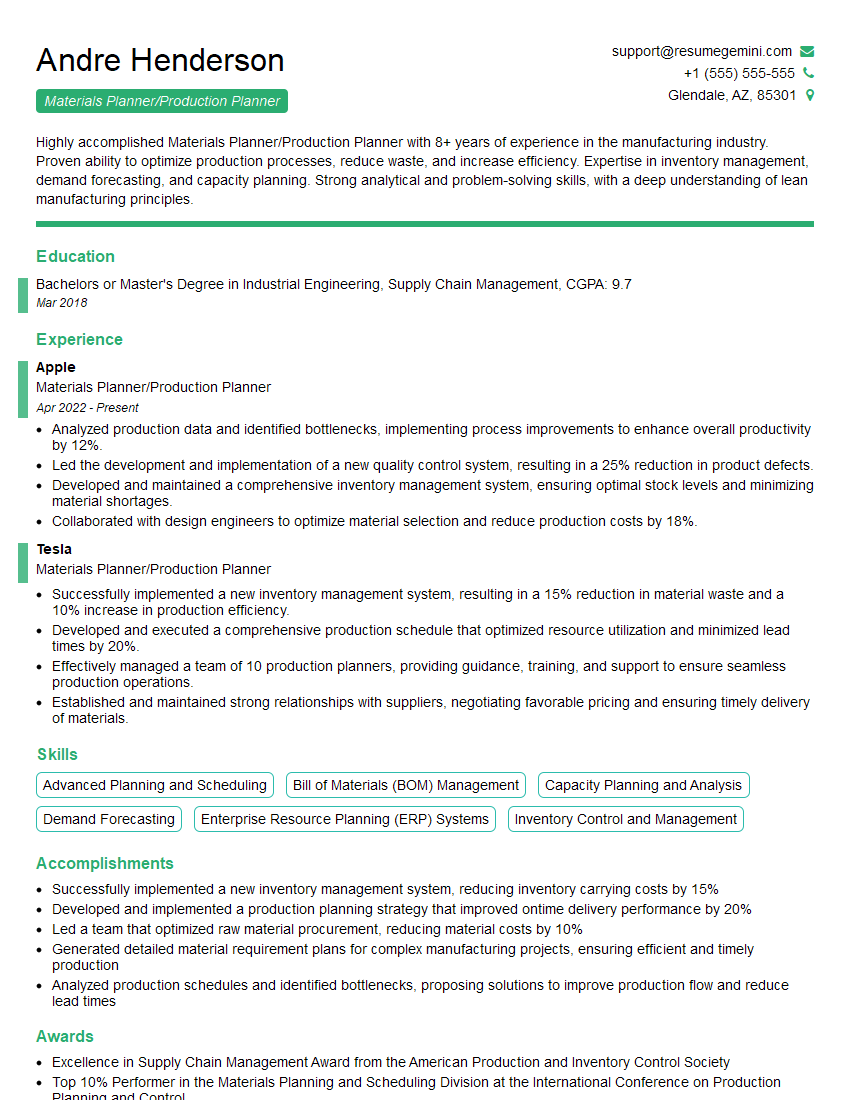

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Materials Planner/Production Planner

1. Explain the key differences between material planning and production planning?

Material planning focuses on ensuring the availability of materials for production, while production planning determines the sequence and timing of production activities. Key differences include:

- Scope: Material planning manages raw materials and components, while production planning oversees the entire production process.

- Time Horizon: Material planning typically covers a longer-term perspective (months to years), while production planning focuses on a shorter-term horizon (days to weeks).

- Objectives: Material planning aims to optimize inventory levels and avoid shortages, while production planning seeks to maximize efficiency and minimize production costs.

2. How do you determine the appropriate safety stock levels for materials?

I use a formula that considers factors such as:

Demand Variability

- Standard deviation of demand

- Coefficient of variation

Lead Time Variability

- Standard deviation of lead time

- Lead time safety factor

Service Level

- Desired probability of not running out of stock

- Z-score

3. Describe how you would develop a master production schedule?

I would follow a structured approach by:

- Forecast Demand: Analyze historical data and market trends to predict future demand.

- Aggregate Demand: Combine demand for similar products into product families or groups.

- Establish Production Plan: Determine the production quantities and timing required to meet demand.

- Allocate Capacity: Ensure that production capacity is available to fulfill the plan.

- Level Production: Smooth out production rates to minimize inventory fluctuations and improve efficiency.

- Finalize Schedule: Prepare a detailed master production schedule outlining production activities.

4. What techniques do you use to optimize inventory levels?

I employ various techniques such as:

- ABC Analysis: Classify inventory items based on value and usage to prioritize inventory management.

- Just-in-Time (JIT) Inventory: Minimize inventory levels by receiving materials only when needed.

- Vendor Managed Inventory (VMI): Collaborate with suppliers to manage inventory levels on their behalf.

- Kanban System: Pull-based inventory system that signals the need for replenishment when inventory levels fall below a certain threshold.

5. How do you ensure that production plans are aligned with business objectives?

I align production plans with business objectives through:

- Regular Reviews: Collaborate with stakeholders to review production plans and ensure alignment with business priorities.

- Flexibility: Develop production plans that allow for adjustments in case of changes in market conditions or customer requirements.

- Communication: Communicate production plans clearly to all relevant departments and keep them informed of any changes.

6. What software tools do you use for materials and production planning?

I have experience with:

- Enterprise Resource Planning (ERP) Systems: SAP, Oracle E-Business Suite

- Materials Requirement Planning (MRP) Software: NetSuite ERP, IQMS

- Production Scheduling Software: OptiSched, Shiftwork

7. Describe your experience in implementing Kanban systems in a manufacturing environment.

In my previous role, I implemented a Kanban system to improve inventory control and production efficiency. I:

- Identified production bottlenecks and determined optimal inventory levels for each Kanban card.

- Trained employees on the Kanban system and its benefits.

- Monitored and adjusted the Kanban system based on production performance and feedback.

- Result: Reduced inventory levels by 20% and improved production throughput by 15%.

8. How do you handle supplier performance issues that impact production planning?

I address supplier performance issues through:

- Communication: Proactively communicate with suppliers to identify potential issues and find solutions.

- Performance Monitoring: Track supplier performance using key performance indicators (KPIs) such as on-time delivery and quality.

- Supplier Development: Work with suppliers to improve their performance through training, process improvements, and incentives.

9. Explain how you would optimize production scheduling to minimize waste and improve efficiency.

To optimize production scheduling, I use techniques such as:

- Production Smoothing: Level production rates to reduce inventory fluctuations and waste.

- Batch Scheduling: Group similar products together to reduce setup times and improve efficiency.

- Sequencing: Prioritize production orders based on factors such as due dates, setup times, and machine availability.

- Simulation Modeling: Use software to simulate different scheduling scenarios and identify the optimal plan.

10. Describe your approach to demand forecasting for production planning.

I use a combination of quantitative and qualitative techniques for demand forecasting:

Quantitative Methods

- Time Series Analysis

- Exponential Smoothing

- Regression Analysis

Qualitative Methods

- Market Research

- Customer Surveys

- Salesforce Input

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Materials Planner/Production Planner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Materials Planner/Production Planner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Materials Planners/Production Planners play a pivotal role in ensuring seamless production operations by managing material requirements, production schedules, and logistics efficiently.

1. Material Planning

Develop and maintain material requirements plans based on production schedules, inventory levels, and historical data.

- Forecast material demand and coordinate with suppliers to secure timely deliveries.

- Monitor inventory levels, identify potential shortages, and implement contingency plans to prevent disruptions.

2. Production Planning

Establish and manage production schedules to optimize production efficiency, meet customer demand, and minimize lead times.

- Coordinate with engineering, sales, and operations teams to gather inputs and align production plans with business objectives.

- Assign production tasks, allocate resources, and sequence operations to maximize productivity.

3. Logistics Management

Manage the movement of raw materials, finished goods, and equipment to ensure timely delivery and optimize inventory levels.

- Plan transportation routes, coordinate shipments, and track inventory levels throughout the supply chain.

- Collaborate with carriers, logistics providers, and warehousing facilities to ensure efficient and cost-effective distribution.

4. Continuous Improvement

Continuously monitor and evaluate production processes to identify areas for improvement and enhance overall efficiency.

- Analyze production data, identify bottlenecks, and develop solutions to streamline operations.

- Implement lean manufacturing principles, automation technologies, and process improvements to optimize production.

Interview Tips

To ace the interview for a Materials Planner/Production Planner role, here are some tips and preparation hacks:

1. Research the Company and Industry

Thoroughly research the company’s products, services, and industry dynamics. This demonstrates your interest and understanding of the role’s context.

- Visit the company website, read industry publications, and connect with current or former employees.

- Identify specific projects or initiatives that align with your skills and interests, and prepare questions to discuss them.

2. Highlight Your Relevant Experience and Skills

Emphasize your experience and accomplishments in material planning, production planning, logistics management, and continuous improvement.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your successes.

- Quantify your achievements whenever possible, using metrics such as cost savings, efficiency gains, or production improvements.

3. Showcase Your Analytical and Problem-Solving Abilities

Interviewers will assess your ability to analyze data, identify issues, and develop solutions.

- Share examples of how you used data analysis to optimize material requirements or production schedules.

- Discuss your approach to problem-solving and provide specific instances where you successfully resolved production or logistics challenges.

4. Emphasize Your Communication and Collaboration Skills

Materials Planners/Production Planners collaborate extensively with different teams and departments.

- Highlight your ability to communicate effectively, both verbally and in writing.

- Provide examples of how you successfully managed relationships with suppliers, customers, or colleagues.

Next Step:

Now that you’re armed with the knowledge of Materials Planner/Production Planner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Materials Planner/Production Planner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini