Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mattress Filling Machine Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

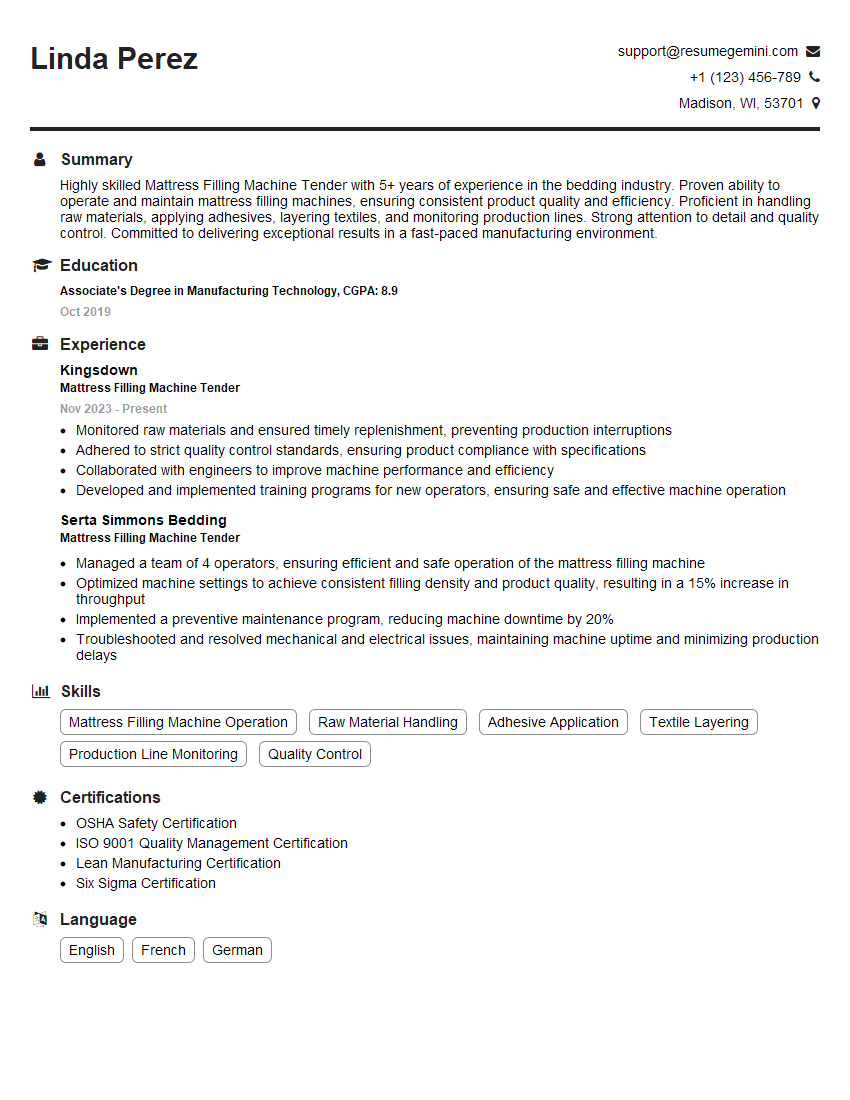

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mattress Filling Machine Tender

1. Describe the key responsibilities of a Mattress Filling Machine Tender?

In my role as a Mattress Filling Machine Tender, I would be responsible for:

- Operating and maintaining mattress filling machines to ensure efficient and safe production.

- Monitoring the filling process and making adjustments to ensure the correct amount and distribution of filling material.

- Performing regular maintenance and cleaning of the machine to minimize downtime and ensure optimal performance.

- Conducting quality control checks on filled mattresses to ensure they meet specifications and customer requirements.

- Working closely with production supervisors and other team members to ensure smooth operation and meet production targets.

2. Explain the different types of mattress filling materials and their properties?

- Foam: Polyurethane foam is a common filling material known for its comfort, support, and durability. It can vary in firmness and density to suit different preferences.

- Memory Foam: Memory foam conforms to the body’s shape, providing pressure relief and support. It is often used in high-end mattresses.

- Latex: Natural or synthetic latex is a resilient and breathable material that offers excellent support and durability. It is hypoallergenic and resistant to dust mites.

- Cotton: Cotton is a natural fiber that is soft, breathable, and absorbent. It is often used in combination with other materials to provide comfort and support.

- Wool: Wool is a natural fiber that is warm, insulating, and moisture-wicking. It is often used in winter mattresses or as an additional layer for added warmth.

3. What are the safety precautions that need to be taken when operating a Mattress Filling Machine?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a mask, to prevent injuries from flying debris or dust.

- Ensure the machine is properly grounded and all electrical connections are secure to prevent electrical hazards.

- Never attempt to clean or maintain the machine while it is in operation to avoid accidents.

- Be aware of potential pinch points and moving parts and keep fingers and loose clothing away from them.

- Follow established safety protocols and report any hazardous conditions or potential safety risks to a supervisor immediately.

4. How do you troubleshoot common problems that may occur with a Mattress Filling Machine?

- Insufficient filling: Check the material supply and hopper, ensure the filling is flowing smoothly, and adjust the machine settings if necessary.

- Uneven filling: Inspect the distribution system and make adjustments to the flow rate or nozzle position to achieve even distribution.

- Machine jams: Stop the machine immediately, clear any obstructions, and check for damage to the filling system or conveyor belt.

- Material defects: Examine the filling material for any abnormalities or contamination that may affect the filling process.

- Electrical issues: Check for loose connections, faulty wires, or blown fuses and contact a qualified electrician for repairs.

5. What is the importance of quality control in mattress production and how do you ensure the quality of filled mattresses?

- Quality control is crucial to ensure the mattresses meet customer expectations and industry standards for comfort, support, and durability.

- As a Mattress Filling Machine Tender, I would conduct regular inspections of filled mattresses to verify the correct amount and distribution of filling.

- I would also check for any defects or abnormalities in the filling material or the mattress’s construction.

- By adhering to quality control procedures and maintaining high standards, I contribute to the production of high-quality mattresses that meet customer satisfaction.

6. Describe how you would maintain a clean and organized work area around the Mattress Filling Machine?

- Daily cleaning: Regularly sweep or vacuum the work area to remove debris and dust.

- Wipe down surfaces: Use a damp cloth to clean the machine’s exterior, control panels, and surrounding surfaces.

- Empty waste bins: Dispose of empty filling material bags, scraps, and other waste promptly.

- Organize materials: Keep filling materials, tools, and equipment neatly stored and easily accessible.

- Prevent spills: Use spill trays or containment devices to prevent spillage of filling materials and maintain a safe and clean work environment.

7. How do you stay up-to-date with advancements in mattress filling technology and industry best practices?

- Attend industry conferences and workshops to learn about new technologies and trends.

- Read trade publications and online resources to stay informed about industry advancements.

- Consult with equipment manufacturers and suppliers to gain insights into product updates and best practices.

- Participate in training programs offered by the company or external organizations to enhance skills and knowledge.

- Network with other professionals in the field to exchange ideas and information.

8. How do you handle working in a fast-paced production environment with tight deadlines?

- Prioritize tasks: Identify the most critical tasks and allocate time accordingly.

- Time management: Use effective time management techniques to ensure efficient workflow and meet deadlines.

- Effective communication: Communicate clearly with colleagues and supervisors to ensure smooth coordination and avoid delays.

- Problem-solving: Quickly identify and resolve any issues that may arise during the production process to minimize downtime.

- Adaptability: Be flexible and adaptable to changing production demands and unexpected situations.

9. Describe a time when you successfully resolved a complex issue with a Mattress Filling Machine?

10. How do you contribute to maintaining a positive and collaborative work environment within the production team?

- Communication: Communicate effectively with colleagues and supervisors, fostering open and positive interactions.

- Teamwork: Collaborate with team members, sharing knowledge, assisting with tasks, and supporting each other.

- Respect: Treat colleagues with respect, valuing their contributions and perspectives.

- Problem-solving: Actively participate in finding solutions to challenges and contribute ideas to improve the work environment.

- Positive attitude: Maintain a positive and enthusiastic attitude, contributing to a pleasant and productive work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mattress Filling Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mattress Filling Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mattress Filling Machine Tenders are responsible for operating and maintaining mattress filling machines. They work in a fast-paced environment and must be able to meet production quotas while maintaining quality standards.

1. Operate mattress filling machines

Mattress Filling Machine Tenders operate mattress filling machines to fill mattresses with foam, fiber, or other materials.

- Load materials into the machine

- Set up the machine according to the desired fill level

- Start the machine and monitor its operation

- Unload finished mattresses from the machine

2. Inspect mattresses

Mattress Filling Machine Tenders inspect mattresses for defects before they are packaged and shipped. They check for:

- Holes or tears in the fabric

- Uneven filling

- Lumps or bumps in the mattress

3. Maintain mattress filling machines

Mattress Filling Machine Tenders perform routine maintenance on mattress filling machines to keep them in good working order. They:

- Clean and lubricate the machine

- Check for loose or worn parts

- Make minor repairs as needed

4. Troubleshoot problems

Mattress Filling Machine Tenders troubleshoot problems with mattress filling machines. They:

- Identify the source of the problem

- Make repairs or adjustments as needed

- Restart the machine and monitor its operation

Interview Tips

To prepare for an interview for a Mattress Filling Machine Tender position, it is important to review the job description and key responsibilities. You should also research the company and its products. Here are some additional tips to help you ace the interview:

1. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a manufacturing environment. You should also avoid wearing strong perfumes or colognes.

2. Be on time

Punctuality is important in any job, but it is especially important in a manufacturing environment. Be sure to arrive for your interview on time, or even a few minutes early. This will show the interviewer that you are reliable and respectful of their time.

3. Be prepared to answer questions about your experience

The interviewer will likely ask you about your experience operating mattress filling machines. Be sure to highlight your skills and experience in this area. You should also be prepared to answer questions about your troubleshooting and problem-solving skills.

4. Be enthusiastic

It is important to show the interviewer that you are enthusiastic about the position and the company. Be positive and upbeat, and be sure to ask questions about the company and the position. This will show the interviewer that you are interested in the job and that you are willing to learn.

5. Be prepared to talk about your safety record

Safety is important in a manufacturing environment. Be sure to highlight your safety record and your commitment to following safety procedures. You should also be prepared to answer questions about your experience with safety equipment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mattress Filling Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.