Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mc Kay Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mc Kay Machine Operator so you can tailor your answers to impress potential employers.

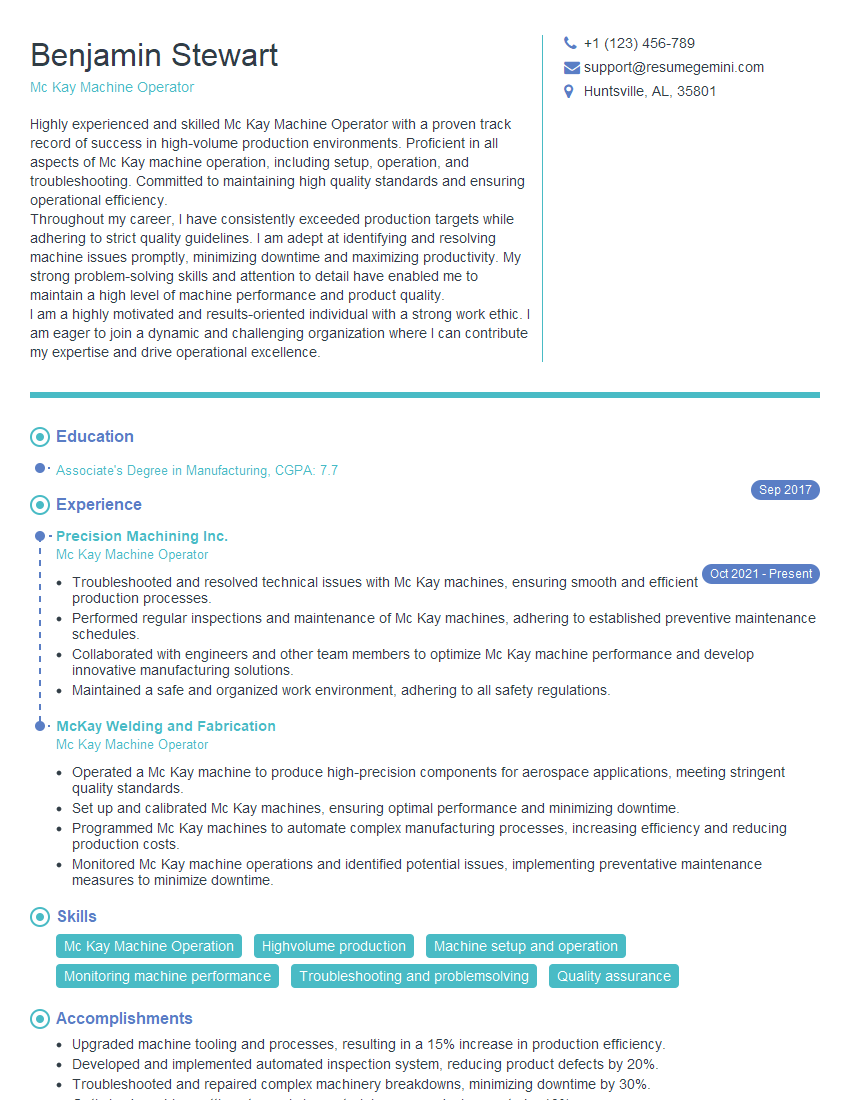

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mc Kay Machine Operator

1. What are the different types of McKay machines and their applications?

McKay machines are essential pieces of equipment used in various industrial applications. Different types of McKay machines include:

- McKay hand seamers: These machines are handheld devices used for seaming metal sheets together in cylindrical or conical shapes. They are commonly employed in industries such as HVAC, roofing, and metal fabrication.

- McKay power seamers: These machines are larger, automated versions of hand seamers, designed for higher production rates. They are used in industries like automotive, appliance manufacturing, and shipbuilding.

- McKay flangers: Flangers are used to create flanges or lips on metal sheets. They are commonly found in the automotive, aerospace, and construction industries.

- McKay welders: McKay welders are used to join metal sheets together using a variety of welding techniques, including resistance welding, arc welding, and spot welding. They are widely used in industries such as automotive, construction, and manufacturing.

2. What are the key factors to consider when selecting the right McKay machine for a specific application?

Factors to consider when selecting a McKay machine:

- The type of metal being worked on (e.g., steel, aluminum, stainless steel)

- The thickness of the metal

- The desired seam type (e.g., Pittsburgh, standing, flat)

- The production rate required

- The available budget

Additional factors to consider:

- The machine’s portability and weight

- The availability of accessories and tooling

- The manufacturer’s reputation and support

3. Explain the process of setting up and operating a McKay hand seamer.

- Mount the appropriate seaming rolls for the desired seam type.

- Adjust the roll pressure and speed according to the metal type and thickness.

- Position the metal sheets between the rolls and engage the seaming head.

- Guide the machine along the seam line, ensuring proper overlap and alignment.

- Monitor the seam quality and make adjustments as needed.

4. How do you maintain and troubleshoot a McKay machine?

Maintaining and troubleshooting a McKay machine involves the following steps:

- Regularly cleaning and lubricating the machine

- Inspecting the rolls and other components for wear or damage

- Checking and adjusting the machine’s settings

- Troubleshooting common problems such as poor seam quality, machine jams, or leaks

- Consulting the manufacturer’s manual or seeking professional assistance for more complex issues

5. What safety precautions should be taken when operating a McKay machine?

- Wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Keep hands and loose clothing away from moving parts.

- Ensure the machine is properly grounded to prevent electrical hazards.

- Never operate the machine under the influence of drugs or alcohol.

- Follow all manufacturer’s safety instructions and guidelines.

6. What is your experience with using McKay machines?

In my previous role as a sheet metal fabricator, I was responsible for operating and maintaining various McKay machines, including hand seamers, power seamers, and flangers. I have experience in setting up, operating, and troubleshooting these machines to produce high-quality seams in a variety of metal types and thicknesses.

7. What is your understanding of the different types of seams produced by McKay machines?

McKay machines can produce various seam types, including:

- Pittsburgh seams: These seams are characterized by a double fold and are commonly used in roofing and HVAC applications.

- Standing seams: These seams are formed by bending the metal sheets at a 90-degree angle, creating a raised seam. They are often used in architectural applications for their aesthetic appeal.

- Flat seams: These seams are created by overlapping the metal sheets and flattening them together. They are commonly used in applications where a smooth, low-profile seam is desired.

8. How do you ensure the quality of seams produced by McKay machines?

- Properly setting up the machine according to the metal type and thickness

- Maintaining the machine regularly to ensure optimal performance

- Monitoring the seam quality during operation and making adjustments as needed

- Using high-quality materials and following proper seaming techniques

- Conducting regular inspections to identify and address any potential issues

9. What are some of the challenges you have faced while operating McKay machines?

Some challenges I have encountered include:

- Ensuring proper seam quality when working with thin or delicate metals

- Troubleshooting machine malfunctions and identifying the root cause

- Maintaining a high production rate while adhering to quality standards

- Working with complex or irregularly shaped metal pieces

- Staying up-to-date on the latest machine technologies and best practices

10. What are your career goals and how do you see this role contributing to your professional development?

My career goal is to become a skilled and experienced sheet metal fabricator. I believe that this role would provide me with valuable opportunities to enhance my existing skills, learn new techniques, and contribute to challenging projects. I am particularly interested in gaining in-depth knowledge of McKay machines and their applications, as well as developing my problem-solving and troubleshooting abilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mc Kay Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mc Kay Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mc Kay Machine Operators play a crucial role in the manufacturing process. Their primary responsibility is to operate and maintain McKay machines, specialized welding equipment used to join metal components.

1. Machine Operation

Mc Kay Machine Operators are responsible for the safe and efficient operation of McKay machines. Their duties include:

- Loading and unloading metal components onto and off of the machine

- Setting up and adjusting the machine according to job specifications

- Monitoring the welding process and making necessary adjustments to ensure proper weld quality

- Inspecting the welded components for defects and adherence to quality standards

2. Machine Maintenance

To ensure the smooth functioning of McKay machines, operators are also responsible for regular maintenance tasks, such as:

- Cleaning and lubricating the machine

- Replacing worn or damaged parts

- Troubleshooting and resolving minor mechanical issues

- Reporting any major issues or maintenance needs to supervisors

3. Safety and Compliance

Operators must adhere to all safety regulations and company policies while working with McKay machines. Their responsibilities include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and hearing protection

- Following proper lockout/tagout procedures when servicing or repairing the machine

- Maintaining a clean and organized work area to prevent accidents

- Reporting any safety hazards or concerns to supervisors

4. Quality Control

Mc Kay Machine Operators play a vital role in ensuring the quality of welded components. Their responsibilities include:

- Inspecting welded components for defects using visual inspection techniques

- Using measuring tools to verify that the welds meet specifications

- Documenting any defects or non-conformances

- Working with quality control personnel to resolve quality issues

Interview Tips

To ace the interview for a Mc Kay Machine Operator position, candidates must demonstrate their technical skills, attention to detail, and commitment to safety and quality. Here are some interview tips to help you prepare:

1. Research the Company and Position

Take the time to learn about the company you’re applying to and the specific role you’re interviewing for. This will help you understand the company’s culture and values, as well as the key responsibilities and expectations for the position. You can find this information on the company’s website, LinkedIn page, or by reading industry publications.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This will help you feel more confident and prepared during the actual interview. Some common interview questions for Mc Kay Machine Operator positions include:

- Tell me about your experience operating McKay machines.

- What are your strengths and weaknesses as a Mc Kay Machine Operator?

- How do you ensure the quality of your welds?

- What are your safety procedures when working with McKay machines?

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the job. This includes your technical skills, attention to detail, and commitment to safety and quality. Be sure to provide specific examples of your work experience to demonstrate your abilities. For example, you could talk about a time when you successfully troubleshoot a mechanical issue with a McKay machine or a time when you identified a quality defect and worked with quality control personnel to resolve the issue.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role. Some good questions to ask include:

- What are the company’s growth plans for the future?

- What are the opportunities for advancement within the company?

- What is the company’s safety record?

- What is the company’s commitment to quality?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mc Kay Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!