Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Measuring Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Measuring Machine Operator so you can tailor your answers to impress potential employers.

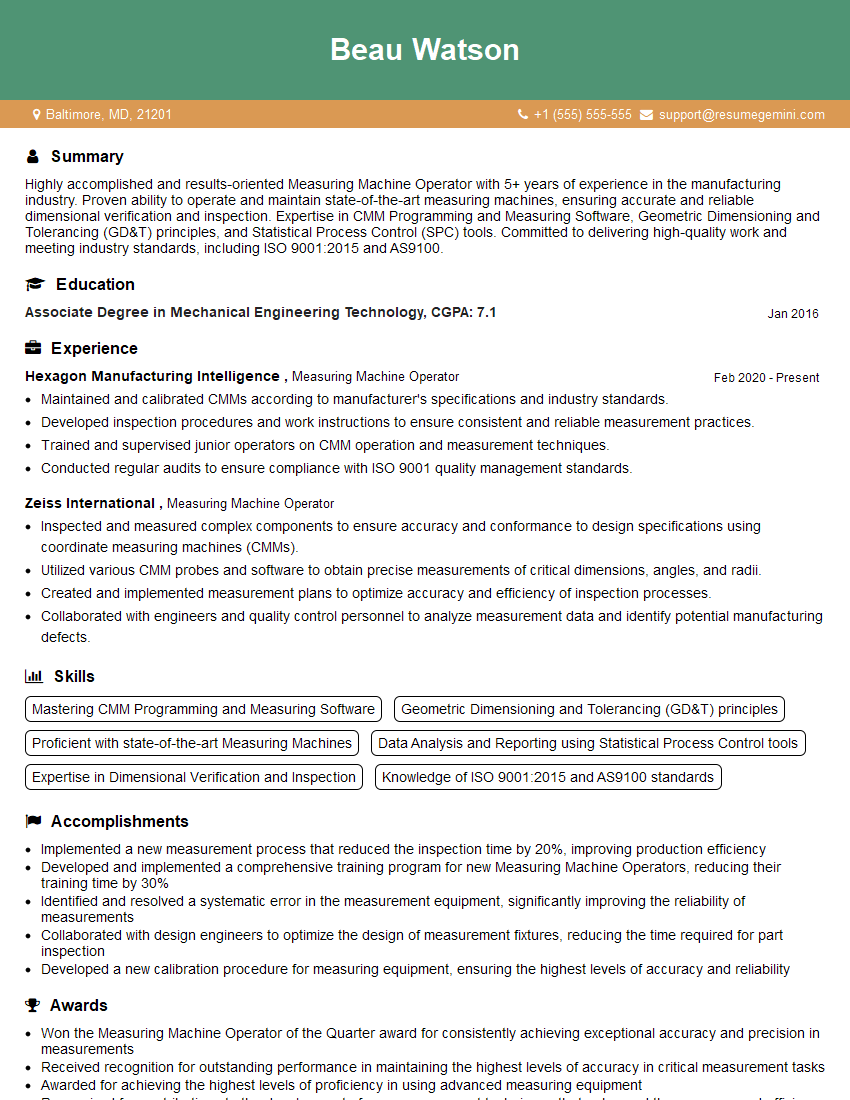

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Measuring Machine Operator

1. Describe the process of calibrating a CMM.

The calibration process of a CMM involves the following steps:

- Establish a stable environment for the CMM.

- Use a certified calibration artifact or standard to verify the accuracy of the CMM.

- Compare the CMM’s measurements to the known dimensions of the artifact.

- Adjust the CMM’s settings as necessary to bring it within specified tolerances.

- Document the calibration results and maintain traceability.

2. How do you ensure the accuracy of measurements taken with a CMM?

Calibration and Verification

- Regularly calibrate the CMM using certified artifacts.

- Verify the CMM’s accuracy by comparing measurements to known standards.

Environmental Control

- Maintain a stable temperature and humidity environment.

- Minimize vibrations and other environmental factors that can affect accuracy.

Operator Training and Technique

- Ensure operators are properly trained and follow established procedures.

- Use appropriate probing techniques and stylus selections.

Software Validation

- Validate the CMM’s software using certified test routines.

- Ensure software updates are applied and tested before use.

3. What are some common sources of error in CMM measurements?

Common sources of error in CMM measurements include:

- Calibration errors: Incorrect calibration of the CMM or artifacts.

- Environmental factors: Temperature fluctuations, humidity, vibrations.

- Operator error: Improper probing techniques, data entry mistakes.

- Software errors: Bugs or glitches in the CMM software.

- Artifact errors: Defects or inaccuracies in the calibration artifacts.

4. How do you handle out-of-tolerance measurements?

When out-of-tolerance measurements are encountered:

- Verify the measurement by repeating it multiple times.

- Check the calibration status of the CMM and artifacts.

- Examine the part and identify any potential defects or variations.

- Consult with supervisors or engineers to determine the appropriate course of action.

- Document the out-of-tolerance condition and any corrective actions taken.

5. Describe the different types of probes used in CMMs.

- Contact probes: Direct physical contact with the surface being measured.

- Non-contact probes: Use lasers, sensors, or other methods to measure without touching.

- Scanning probes: Continuous scanning of surfaces to create point clouds or 3D models.

- Renishaw probes: Specialized probes with advanced capabilities, such as touch-triggering and optical scanning.

6. What are the advantages of using a CMM over other measurement methods?

- High accuracy and precision: CMMs provide highly precise and accurate measurements.

- Repeatability: CMMs can produce consistent and repeatable measurements over time.

- Versatility: CMMs can measure a wide range of sizes, shapes, and materials.

- Data collection capabilities: CMMs can generate detailed measurement data for analysis and documentation.

- Automation: CMMs can be automated for faster and more efficient measurements.

7. How do you interpret CMM measurement reports?

To interpret CMM measurement reports:

- Review the overall measurements and tolerances.

- Identify any out-of-tolerance conditions or areas of concern.

- Analyze the measurement data for trends or patterns.

- Compare the results to previous measurements or design specifications.

- Generate reports or summaries for further analysis or action.

8. What are some best practices for CMM programming?

- Use clear and concise programming language.

- Follow established naming conventions and documentation standards.

- Optimize probe paths for efficiency and accuracy.

- Establish appropriate measurement parameters and tolerances.

- Thoroughly test and validate programs before running them.

9. How do you stay up-to-date with the latest advancements in CMM technology?

- Attend industry conferences and exhibitions.

- Read technical publications and whitepapers.

- Participate in online forums and discussions.

- Network with other professionals in the field.

- Pursue ongoing training and certification opportunities.

10. How do you handle the inspection of complex parts?

Inspecting complex parts with a CMM involves:

- Understanding the design specifications and tolerances.

- Determining appropriate measurement points and probe paths.

- Using specialized fixtures or adapters to hold the part securely.

- Employing scanning techniques to capture detailed surface data.

- Analyzing the measurement results and comparing them to 3D models or CAD data.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Measuring Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Measuring Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Measuring Machine Operators are responsible for the precision measurement and inspection of manufactured parts using a variety of measuring machines. They play a crucial role in ensuring the quality and accuracy of products by verifying that they meet specified dimensions and tolerances.

1. Machine Operation

Operate and maintain measuring machines, including coordinate measuring machines (CMMs), optical comparators, and laser scanners, to measure and inspect parts.

2. Measurement and Inspection

Conduct precise measurements of parts to ensure they meet specifications and tolerances. Identify and document any deviations from the expected dimensions.

3. Data Analysis

Analyze measurement data and generate reports that summarize findings and identify any potential quality issues.

4. Quality Assurance

Monitor and maintain quality standards throughout the manufacturing process. Work with production teams to resolve quality issues and implement corrective actions.

5. Instrument Calibration

Calibrate and maintain measuring machines according to established standards and procedures.

6. Process Improvement

Participate in process improvement initiatives to optimize measurement processes and enhance accuracy.

7. Training

Provide training and support to other operators on the use and maintenance of measuring machines.

8. Safety

Comply with all safety regulations and procedures related to the operation of measuring machines and the handling of parts.

Interview Tips

Preparing thoroughly for a Measuring Machine Operator interview is essential to showcase your skills and knowledge. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company’s industry, products, and culture. Read the job description carefully to understand the specific responsibilities and requirements of the position.

2. Practice Your Technical Skills

Review your knowledge of measuring machines, including their capabilities and applications. Practice using data analysis software and generating reports.

3. Quantify Your Accomplishments

When describing your experience, use specific numbers and metrics to quantify your accomplishments. For example, instead of saying “I inspected parts,” you could say “I inspected over 1,000 parts per day, ensuring accuracy within 0.001 inches.”

4. Be Prepared to Discuss Quality Assurance

Highlight your understanding of quality control principles and procedures. Explain how you have implemented and maintained quality standards in your previous roles.

5. Emphasize Safety

Demonstrate your commitment to safety by describing your knowledge of industry regulations and best practices. Explain how you have implemented safety measures in your work.

6. Show Your Team Spirit

Measuring Machine Operators often work closely with production teams and other departments. Emphasize your ability to work effectively in a team environment and contribute to the overall success of the company.

7. Be Enthusiastic and Positive

Show your enthusiasm for the field of metrology and your desire to contribute to the company’s success. A positive attitude can make a memorable impression on the interviewer.

8. Dress Professionally

First impressions matter, so dress professionally for the interview. This shows that you take the opportunity seriously and respect the interviewer’s time.

Next Step:

Now that you’re armed with the knowledge of Measuring Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Measuring Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini