Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Meat Grading Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

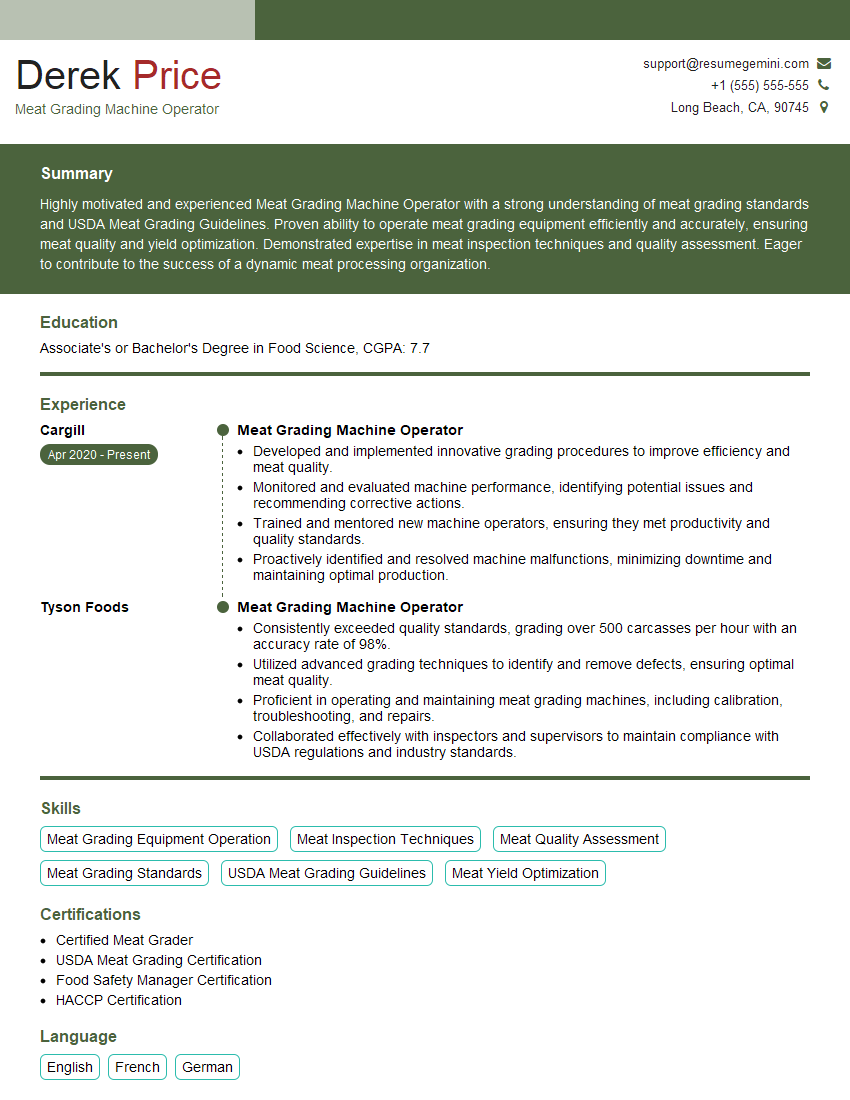

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Meat Grading Machine Operator

1. Describe the grading standards you use to determine the quality of meat.

I use the United States Department of Agriculture (USDA) quality grading standards to determine the quality of meat. These standards are based on the meat’s maturity, marbling, texture, and color. I visually inspect the meat and assess its quality based on these factors.

- Maturity: I check the meat’s maturity by examining its bones and cartilage. Young animals have tender and immature bones, while older animals have tougher and more mature bones.

- Marbling: I assess the meat’s marbling by looking at the amount and distribution of fat within the muscle. Good marbling indicates that the meat will be tender and juicy.

- Texture: I evaluate the meat’s texture by feeling it. Firm and elastic meat indicates good quality, while soft and flabby meat indicates poor quality.

- Color: I inspect the meat’s color to determine its freshness. Bright red meat is typically fresh, while dull or brown meat may be older or less desirable.

2. How do you ensure the accuracy and consistency of your grading?

Calibration and Training

- I regularly participate in calibration exercises to ensure that my grading is accurate and consistent with USDA standards.

- I attend training sessions to stay up-to-date on the latest grading techniques and industry best practices.

Double-Checking and Supervision

- I double-check my grading with other qualified graders to minimize errors.

- My supervisor regularly reviews my work to ensure that I am meeting the required quality standards.

3. What are the most common defects you encounter in meat grading?

The most common defects I encounter in meat grading include:

- Bruising: Bruising occurs when the animal is injured during handling or transportation. It can affect the meat’s appearance and flavor.

- Cuts and tears: Cuts and tears can occur during processing or handling. They can affect the meat’s value and marketability.

- Disease: Animals with diseases or infections may have meat that is unfit for consumption. I am trained to identify and reject meat that shows signs of disease.

- Parasites: Parasites can affect the meat’s quality and safety. I visually inspect the meat for any signs of parasites.

4. How do you handle meat that does not meet the grading standards?

I handle meat that does not meet the grading standards by segregating it from the graded meat. This meat is then directed to be processed into ground beef or other products that do not require a specific grade.

- Proper Labeling: I ensure that all meat that does not meet the grading standards is properly labeled to prevent it from being sold as a higher grade.

- Communication: I communicate with my supervisor and the processing team to ensure that the meat is handled appropriately.

5. What is your understanding of the Hazard Analysis and Critical Control Points (HACCP) system?

HACCP is a systematic approach to identifying, evaluating, and controlling hazards that could occur during the production, processing, and handling of meat. I understand that HACCP is essential for ensuring the safety and quality of meat products.

- Hazard Identification: I am trained to identify potential hazards, such as microbiological contamination, chemical residues, and physical hazards.

- Control Measures: I understand the importance of implementing control measures to prevent or eliminate identified hazards.

- Monitoring: I am responsible for monitoring and verifying that the control measures are effective in preventing hazards.

- Corrective Actions: I am trained to take corrective actions when monitoring detects a deviation from the established critical limits.

6. How do you stay up-to-date on the latest meat grading techniques and industry regulations?

I stay up-to-date on the latest meat grading techniques and industry regulations through the following methods:

- Training and Certification: I attend training sessions and obtain certifications to enhance my knowledge and skills.

- Industry Publications: I read industry publications and journals to stay informed about new techniques and best practices.

- Conferences and Seminars: I participate in conferences and seminars to network with other professionals and learn about advancements in the field.

- Online Resources: I utilize online resources and databases to access up-to-date information and research findings.

7. Describe the steps involved in grading beef carcasses.

- Examination: I visually examine the carcass to assess its overall appearance, conformation, and muscling.

- Maturity Assessment: I evaluate the maturity of the carcass by examining its bones and cartilage.

- Marbling Evaluation: I cut into the carcass to assess the amount and distribution of fat within the muscle.

- Texture and Color Assessment: I examine the texture and color of the meat to determine its quality.

- Final Grade Assignment: Based on my evaluation, I assign the carcass a USDA quality grade, which reflects its overall quality and value.

8. How do you determine the yield grade of a carcass?

I determine the yield grade of a carcass by calculating the percentage of boneless, closely trimmed retail cuts that can be obtained from the carcass.

- Measurements: I take measurements of the carcass, including its length, width, and fat thickness, to estimate its yield.

- Formula: I use a USDA-approved formula to calculate the yield grade based on the measurements.

- Grade Assignment: The yield grade is assigned based on the calculated percentage of retail cuts.

9. What are the different factors that can affect the quality of meat?

- Animal Factors: Breed, age, nutrition, and health of the animal can influence the quality of its meat.

- Production Practices: Farming and handling practices, such as feed, housing, and stress levels, can affect meat quality.

- Processing Factors: Slaughtering, chilling, and aging techniques can impact the meat’s tenderness, flavor, and appearance.

- Storage Conditions: Temperature, humidity, and packaging can affect the meat’s quality and shelf life.

10. Describe your experience in working with automated meat grading machines.

I have extensive experience in working with automated meat grading machines. I am proficient in operating and maintaining these machines, ensuring accurate and efficient grading.

- Machine Operation: I have operated various models of automated meat grading machines.

- Calibration and Maintenance: I am responsible for calibrating and maintaining the machines to ensure their accuracy and proper functioning.

- Data Analysis: I analyze the data generated by the machines to identify trends and improve grading processes.

- Troubleshooting: I am skilled in troubleshooting and resolving any technical issues that arise with the machines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Meat Grading Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Meat Grading Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Meat Grading Machine Operators are accountable for operating and maintaining meat grading machines, ensuring accurate grading and efficient production within meat processing facilities.

1. Machine Operation

Operate meat grading machines to determine the quality and characteristics of meat cuts.

- Calibrate and adjust machines for optimal performance and accuracy.

- Monitor machine performance, identify and resolve any issues promptly.

2. Meat Grading

Assess and grade meat cuts based on established standards, considering factors such as marbling, fat content, and quality.

- Identify and classify different grades of meat accurately and consistently.

- Maintain detailed records of grading results for traceability and quality control.

3. Quality Control

Ensure the accuracy and reliability of meat grading by following established quality control procedures.

- Inspect meat cuts for defects, contamination, or any anomalies.

- Adhere to food safety and sanitation regulations to maintain a hygienic work environment.

4. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on meat grading machines to ensure optimal functionality.

- Clean and lubricate machinery components to prevent breakdowns.

- Identify and resolve minor issues to minimize downtime and maintain productivity.

Interview Tips

Preparing for an interview for a Meat Grading Machine Operator position requires thorough research and practice. Here are some essential tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and industry standing.

- Read the company website, annual reports, and industry publications.

- Research the meat processing industry and its trends to demonstrate your knowledge.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivation.

- Describe your experience in operating and maintaining meat grading machines.

- Explain your understanding of meat grading standards and how you ensure accuracy.

- Discuss your ability to work in a fast-paced and demanding production environment.

3. Emphasize Your Attention to Detail and Quality

Highlight your meticulous nature and commitment to maintaining high-quality standards.

- Provide examples of how you have identified and resolved quality issues in previous roles.

- Explain your understanding of the importance of accurate grading for consumer safety and satisfaction.

4. Demonstrate Your Troubleshooting Abilities

Emphasize your problem-solving skills and ability to handle technical challenges.

- Share examples of how you have diagnosed and resolved machine malfunctions in the past.

- Explain your approach to preventive maintenance and how it helps minimize downtime.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Meat Grading Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.