Are you gearing up for an interview for a Meat Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Meat Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

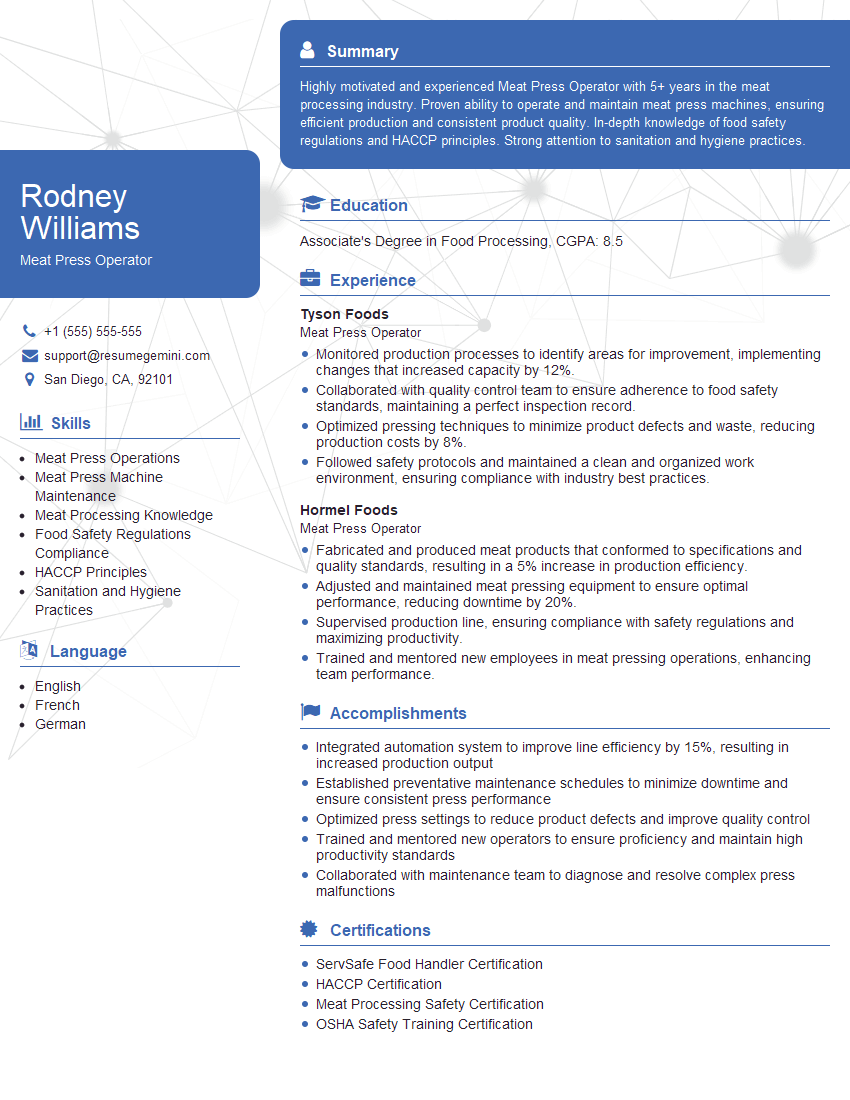

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Meat Press Operator

1. What are the different types of meat presses and what are their uses?

- Hydraulic presses: These presses use hydraulic fluid to generate pressure and are used for high-volume production.

- Mechanical presses: These presses use a mechanical linkage to generate pressure and are used for smaller-scale production.

- Pneumatic presses: These presses use compressed air to generate pressure and are used for fast and precise operations.

2. What are the key safety precautions to follow when operating a meat press?

PPE and Protective Gear

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Use cut-resistant gloves to protect hands from sharp edges and blades.

Machine Operation

- Always follow the manufacturer’s instructions for operating the press.

- Ensure the press is properly set up and calibrated before use.

- Keep hands and other body parts away from moving parts.

- Never attempt to remove or bypass safety guards.

Product Handling

- Inspect meat products before loading them into the press to ensure they are free of bones or other foreign objects.

- Use proper lifting techniques to move heavy products.

Emergency Procedures

- Know the location of emergency stop buttons and how to use them.

- Be aware of fire extinguisher locations and how to use them if necessary.

3. How do you ensure that the meat is pressed to the correct thickness and density?

- Use a thickness gauge: This tool measures the thickness of the pressed meat and ensures it meets specifications.

- Adjust the press settings: The pressure and dwell time of the press can be adjusted to achieve the desired thickness and density.

- Conduct regular quality checks: Sample pressed meat products should be inspected regularly to ensure they meet quality standards.

4. What are the common troubleshooting steps for meat press malfunctions?

- Check power supply: Ensure that the press is properly connected to a power source.

- Inspect hydraulic fluid: Check the level and condition of the hydraulic fluid and replace if necessary.

- Examine pressure settings: Verify that the press is set to the correct pressure for the desired product.

- Lubricate moving parts: Regularly lubricate all moving parts of the press to prevent wear and tear.

- Contact the manufacturer: If the problem persists, contact the manufacturer for technical support.

5. How do you maintain a clean and sanitary work environment around the meat press?

- Regular cleaning: Clean the press and surrounding area daily with a food-grade disinfectant.

- Sanitize work surfaces: All surfaces that come into contact with meat should be sanitized regularly.

- Proper waste disposal: Dispose of meat waste and packaging materials promptly to prevent contamination.

- Pest control: Implement measures to prevent pests from entering the work area.

- Hygiene practices: Encourage employees to follow good hygiene practices, such as washing hands frequently.

6. What are the different types of meat products that can be pressed using a meat press?

- Ground meat patties: These are formed by pressing ground meat into patties of various sizes and thicknesses.

- Sausages: Meat is stuffed into casings and pressed to remove air pockets and achieve the desired shape.

- Deli meats: Processed meats, such as ham, turkey, and pastrami, are sliced and pressed to form uniform slices.

- Bacon: Cured pork belly is pressed to remove excess moisture and flatten the slices.

- Other meat products: Meat press can also be used to form products such as meatloaf, terrines, and dumplings.

7. How do you determine the optimal pressure and dwell time for different meat products?

- Product characteristics: The type of meat, its fat content, and texture influence the optimal pressure and dwell time.

- Desired outcome: The desired thickness, density, and shape of the pressed product should be considered.

- Equipment limitations: The capabilities of the meat press, including its pressure range and dwell time settings, need to be taken into account.

- Trial and error: Experimentation with different pressure and dwell time settings can help determine the optimal parameters for each product.

8. What are the potential risks associated with operating a meat press?

- Crush injuries: Hands or other body parts can be crushed between the press plates.

- Cuts and lacerations: Sharp edges and blades can cause cuts and lacerations.

- Repetitive strain injuries: Prolonged operation of the press can lead to repetitive strain injuries.

- Electrical hazards: The press may pose electrical hazards if not properly grounded and maintained.

- Contamination: Improper handling of meat and failure to maintain a clean work environment can lead to contamination.

9. How do you ensure the quality of pressed meat products?

- Raw material inspection: Inspect incoming meat for freshness, quality, and absence of foreign objects.

- Process control: Monitor the pressure, dwell time, and temperature during the pressing process to ensure consistency.

- Product inspection: Inspect pressed products for proper thickness, density, shape, and any defects.

- Sensory evaluation: Conduct sensory evaluations to assess the texture, flavor, and appearance of the products.

- Traceability: Maintain records of production batches and raw materials to trace products in case of any quality issues.

10. How do you stay updated with the latest advancements in meat pressing technology?

- Attend industry events: Participate in trade shows and conferences to learn about new technologies and best practices.

- Read industry publications: Stay informed by reading industry magazines and journals.

- Connect with experts: Join online forums and connect with other meat press operators to share knowledge and experience.

- Research online: Use online resources to find information about new technologies and equipment.

- Attend training: Take advantage of training opportunities offered by equipment manufacturers or industry organizations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Meat Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Meat Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Meat Press Operators play a crucial role in the food processing industry by operating and maintaining meat pressing machines to produce a variety of meat products. Their responsibilities include:

1. Operating Meat Press Machine

Operate meat pressing machines to form, shape, and press meat into various products such as patties, sausages, and deli slices.

- Adjust machine settings to achieve desired product specifications.

- Monitor machine operation and make necessary adjustments to ensure consistent product quality.

2. Preparing Meat Product

Prepare meat product by grinding, mixing, and seasoning to meet specific customer requirements.

- Follow established recipes and procedures to ensure product quality and safety.

- Maintain a clean and sanitary work area to prevent contamination.

3. Inspecting Product

Inspect finished meat products to ensure they meet quality standards and customer specifications.

- Check for weight, shape, texture, and appearance.

- Remove any defective products from the production line.

4. Maintaining Equipment

Maintain and clean meat press machines, as well as other related equipment, to ensure optimal performance and prevent breakdowns.

- Conduct regular inspections and lubricate moving parts.

- Follow manufacturer’s instructions for maintenance and repairs.

5. Safety and Sanitation

Adhere to all safety regulations and maintain a clean and sanitary work environment.

- Wear appropriate personal protective equipment (PPE).

- Sanitize equipment and surfaces regularly to prevent contamination.

Interview Tips

To help candidates ace their interview for a Meat Press Operator position, here are some essential tips:

1. Research the Company and Industry

Get familiar with the company’s history, mission, products, and industry trends. This knowledge will demonstrate your interest and enthusiasm for the role.

2. Highlight Relevant Skills

Emphasize your experience in operating meat pressing machines and preparing meat products. Also mention any skills in quality control, equipment maintenance, and safety procedures.

3. Show Enthusiasm and Attention to Detail

Convey your passion for the food processing industry and your attention to detail. Explain how you ensure product quality and maintain a high level of hygiene in your work.

4. Prepare Example Responses

Prepare answers to common interview questions such as “Tell me about your experience in operating meat press machines” or “How do you ensure product quality?” Practice delivering your responses clearly and concisely.

5. Dress Professionally and Arrive Punctually

Make a good first impression by dressing professionally and arriving for your interview punctually. This demonstrates your respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Meat Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!