Feeling lost in a sea of interview questions? Landed that dream interview for Meat Stuffer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Meat Stuffer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

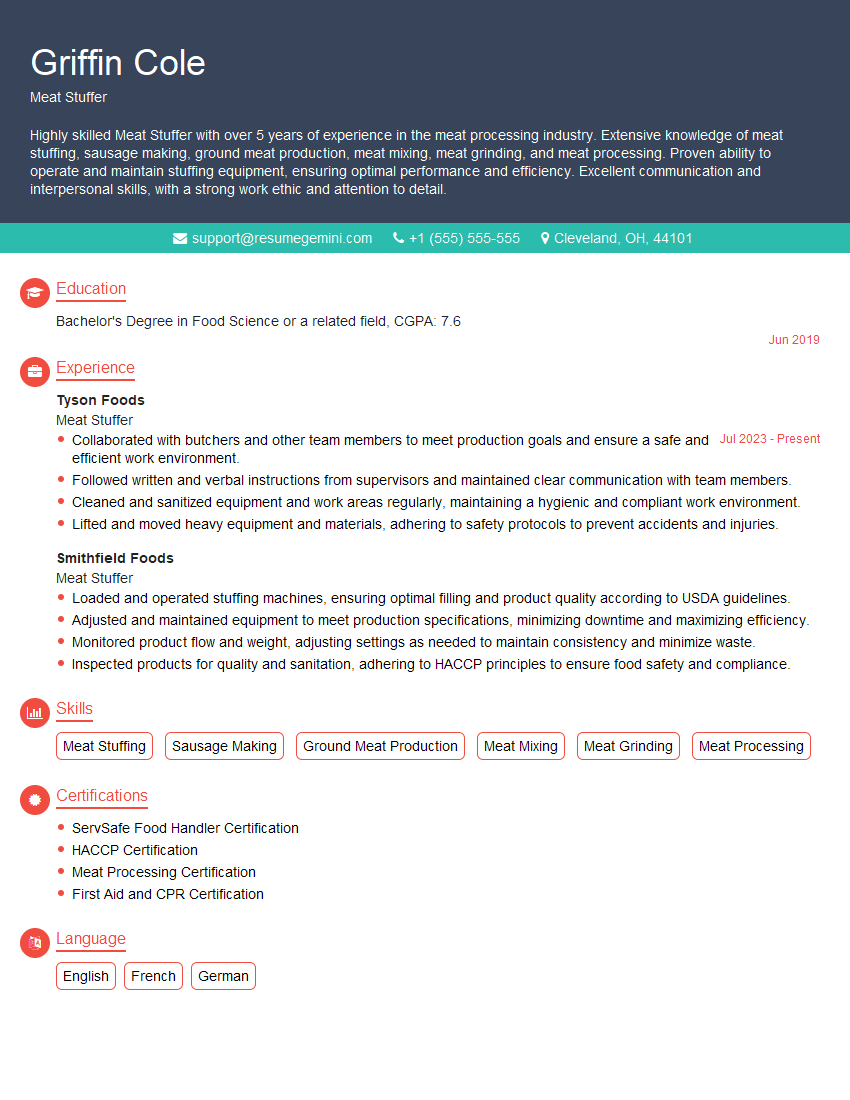

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Meat Stuffer

1. Describe the process of stuffing meat into casings.

The process of stuffing meat into casings involves several key steps:

- Preparing the meat: The meat is first ground or chopped to the desired consistency. It is important to ensure that the meat is properly chilled to prevent spoilage.

- Selecting the casings: The type of casing used depends on the desired finished product. Casings can be made from natural materials such as animal intestines or synthetic materials such as collagen or cellulose.

- Stuffing the meat: The ground meat is then stuffed into the casings using a meat stuffer. The meat is packed tightly into the casings, ensuring that there are no air pockets.

- Tying or sealing the casings: Once the casings are filled, they are tied or sealed to prevent the meat from falling out. This can be done using string, clips, or other methods.

- Smoking or drying the sausages: Depending on the desired finished product, the sausages may be smoked or dried to enhance their flavor and preservation.

2. What are the different types of meat stuffers and their advantages?

Manual meat stuffers

- Advantages: They are relatively inexpensive, easy to use, and can be used for small-scale meat stuffing operations.

Electric meat stuffers

- Advantages: They are more powerful, can handle larger volumes of meat, and are more efficient than manual stuffers.

Hydraulic meat stuffers

- Advantages: They are the most powerful and efficient type of meat stuffer, and are used for large-scale commercial operations.

3. What are the key factors to consider when choosing a meat stuffer?

- Capacity: The capacity of the meat stuffer determines how much meat it can stuff at one time.

- Power: The power of the meat stuffer determines how quickly and efficiently it can stuff meat.

- Type of casings used: The type of casings used will determine the type of meat stuffer required.

- Budget: The budget available will also influence the choice of meat stuffer.

4. How do you maintain and clean a meat stuffer?

- Regular cleaning: The meat stuffer should be cleaned after each use to prevent the buildup of bacteria.

- Disassembling the stuffer: The stuffer should be disassembled into its component parts for thorough cleaning.

- Washing the parts: The parts should be washed with hot soapy water and rinsed thoroughly.

- Sanitizing the parts: The parts should be sanitized using a food-grade sanitizer to kill any remaining bacteria.

- Reassembling the stuffer: The stuffer should be reassembled after cleaning and sanitizing.

5. What are the common problems that can occur when using a meat stuffer and how can they be resolved?

- Air pockets: Air pockets can occur if the meat is not packed tightly into the casings. This can cause the sausages to burst during cooking.

- Leaking casings: Leaking casings can occur if they are not properly sealed. This can result in the loss of meat and juices.

- Clogged stuffer: The stuffer can become clogged if the meat is too coarse or if there are pieces of bone or gristle in the meat.

6. What are the different types of sausage casings and their properties?

Natural casings

- Hog casings: Made from the intestines of hogs, hog casings are the most common type of natural casing.

- Sheep casings: Made from the intestines of sheep, sheep casings are thinner and more delicate than hog casings.

- Beef casings: Made from the intestines of cattle, beef casings are the strongest and most durable type of natural casing.

Synthetic casings

- Collagen casings: Made from collagen, a protein found in animal skin and bones, collagen casings are edible and have a natural appearance.

- Cellulose casings: Made from cellulose, a plant-based fiber, cellulose casings are not edible and are used for non-edible products such as cleaning sponges.

7. How do you calculate the yield of stuffed meat products?

The yield of stuffed meat products is the percentage of the total weight of the meat that is recovered after stuffing. The yield can be calculated using the following formula:

Yield = (Weight of stuffed meat / Weight of original meat) x 100%

8. What are the different factors that can affect the yield of stuffed meat products?

- Type of meat: The type of meat used can affect the yield. For example, leaner meats will have a higher yield than fatty meats.

- Grinding size: The size of the meat grind can also affect the yield. Finer grinds will have a higher yield than coarser grinds.

- Amount of fat: The amount of fat in the meat can also affect the yield. Higher fat content will result in a lower yield.

- Stuffing technique: The technique used to stuff the meat can also affect the yield. Proper stuffing techniques will help to minimize air pockets and ensure a tight pack, which will increase the yield.

9. What are the different types of sausage emulsions and their properties?

Oil-in-water emulsions

- Properties: Stable, creamy texture, easily spreadable

Water-in-oil emulsions

- Properties: Firm, sliceable texture, less spreadable

Factors affecting emulsion stability

- Protein content: Higher protein content helps stabilize emulsions.

- Fat content: Higher fat content can destabilize emulsions.

- Salt content: Salt can help stabilize emulsions.

- pH: The pH of the emulsion can also affect stability.

10. What are the different methods of smoking meat products?

Hot smoking

- Properties: Cooks and smokes the meat simultaneously, produces a juicy and flavorful product.

Cold smoking

- Properties: Smokes the meat without cooking it, produces a drier and more intense flavor.

Factors affecting the smoking process

- Temperature: The temperature of the smokehouse affects the cooking and smoking process.

- Humidity: The humidity of the smokehouse affects the drying process.

- Airflow: The airflow in the smokehouse affects the distribution of smoke and heat.

- Smokewood: The type of smokewood used affects the flavor of the smoked product.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Meat Stuffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Meat Stuffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Meat Stuffers are responsible for operating and maintaining meat stuffing machines to ensure efficient production of meat products.

1. Machine Operation and Maintenance

Operate meat stuffing machines to fill casings with ground meat.

- Monitor machine settings and adjust as needed to produce consistent and high-quality products.

- Clean and maintain machines regularly to prevent breakdowns and ensure optimal performance.

2. Quality Control

Inspect stuffed meat products for weight, size, and appearance to ensure they meet quality standards.

- Weigh stuffed products to ensure they meet required specifications.

- Check for any defects or imperfections in the finished products.

3. Sanitation and Safety

Maintain a clean and sanitary work environment to comply with food safety regulations.

- Wear appropriate personal protective equipment (PPE) to prevent contamination.

- Follow established sanitation procedures to ensure the safety of food products.

4. Efficiency and Productivity

Maximize productivity and efficiency by optimizing machine settings and minimizing downtime.

- Identify and address any bottlenecks in the stuffing process.

- Work efficiently as part of a team to achieve production goals.

Interview Tips

To ace the interview for a meat stuffer position, it’s crucial to prepare effectively and showcase your relevant skills and experience. Here are some tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s background, culture, and the specific requirements of the meat stuffer position.

- Visit the company website and read available materials.

- Reach out to the recruiter or hiring manager for additional information.

2. Highlight Relevant Skills and Experience

Emphasize your skills in operating and maintaining meat stuffing machines, as well as your experience in quality control and sanitation.

- Quantify your accomplishments whenever possible, using specific numbers or metrics.

- Prepare examples of situations where you demonstrated your efficiency and ability to meet production goals.

3. Demonstrate Your Commitment to Safety and Quality

Meat stuffers play a vital role in food safety, so it’s essential to highlight your commitment to maintaining a clean and sanitary work environment.

- Explain your understanding of food safety regulations and your experience in following sanitation procedures.

- Show that you prioritize the safety and quality of the food products you handle.

4. Be Enthusiastic and Show Interest

Express your genuine interest in the meat stuffer position and the company itself.

- Be positive and enthusiastic during the interview.

- Ask thoughtful questions to show your engagement and interest in the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Meat Stuffer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.