Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mechanic Insulator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mechanic Insulator so you can tailor your answers to impress potential employers.

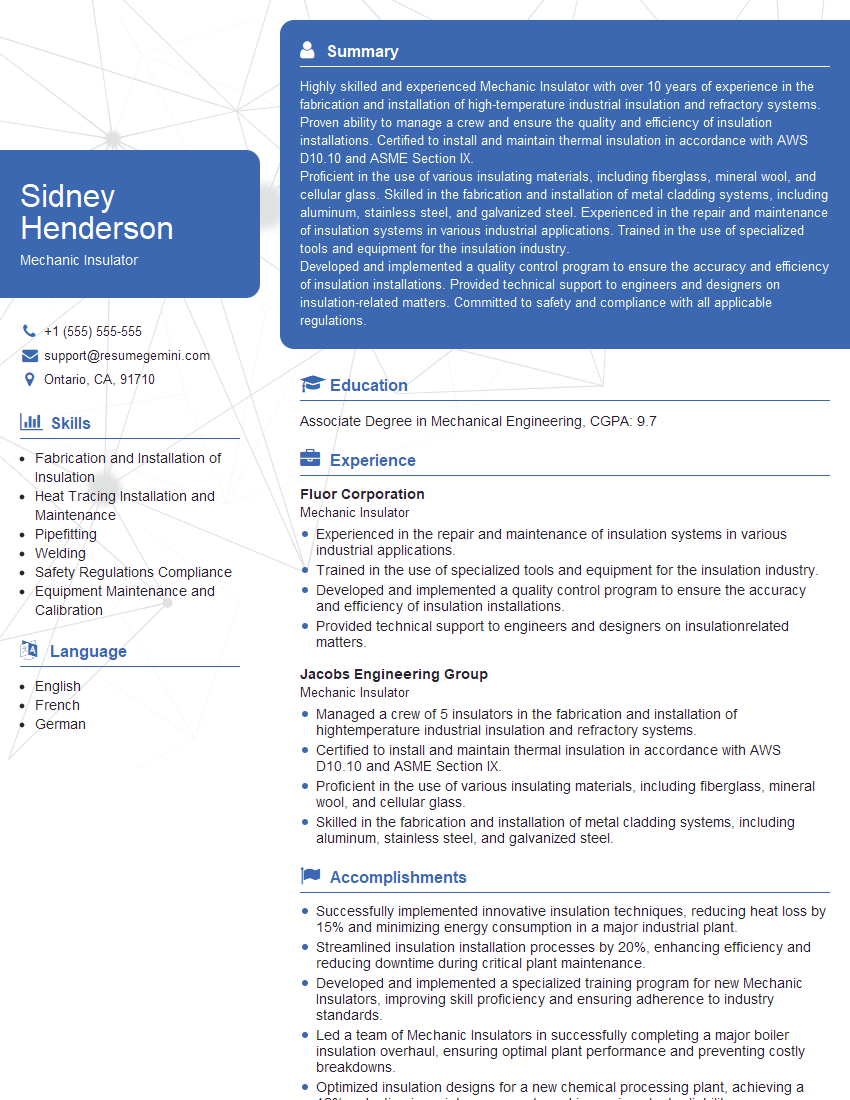

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanic Insulator

1. What are the different types of insulation materials and their applications?

There are various types of insulation materials, each with its unique properties and applications. Here are some common types:

- Fiberglass: Widely used in residential and commercial buildings, it is known for its thermal and acoustic insulation properties.

- Cellulose: Made from recycled paper, cellulose is a sustainable and effective insulator for both thermal and acoustic purposes.

- Polystyrene: Available in rigid and expanded forms, polystyrene is commonly used for thermal insulation in walls, roofs, and foundations.

- Polyurethane: A spray-applied foam insulation, polyurethane offers excellent thermal performance and can fill gaps and seal air leaks.

- Mineral wool: Made from molten rock or slag, mineral wool is fire-resistant and provides good thermal and acoustic insulation.

2. Describe the process of installing insulation in a residential building.

Preparing the Surface

- Inspect the area to ensure it is clean and free of debris.

- Install vapor barriers or air barriers as necessary to prevent moisture penetration.

Installing Insulation

- Select the appropriate insulation material based on the specific application and space requirements.

- Cut the insulation to fit the area and install it snugly between studs, joists, or rafters.

Covering Insulation

- Once the insulation is installed, cover it with drywall, paneling, or other materials to create an air-tight seal.

- Seal any gaps or holes to prevent air leaks.

3. What are the safety precautions to observe when working with insulation materials?

Working with insulation materials requires adherence to strict safety precautions. Here are some essential measures:

- Wear appropriate protective gear: Gloves, face masks, and respirators protect against dust, fiberglass fibers, and other potential irritants.

- Ensure proper ventilation: Open windows or use fans to maintain air circulation and prevent the accumulation of dust or fumes.

- Avoid contact with skin and eyes: Insulation materials can cause irritation or allergic reactions. Keep them away from exposed areas.

- Store materials safely: Store insulation materials in a dry, covered location to prevent moisture absorption and maintain their effectiveness.

4. How do you calculate the R-value of an insulation material?

The R-value is a measure of an insulation material’s thermal resistance. It is calculated by dividing the thickness of the material (in inches) by its thermal conductivity (in BTU/hr-ft² ºF/in). The higher the R-value, the more effective the insulation.

5. What are the different techniques used to measure insulation resistance?

- Megohmmeter: A handheld device that measures resistance by applying a high voltage to the insulation.

- Insulation resistance tester: A specialized instrument designed specifically for testing insulation resistance in electrical systems.

6. Describe the preventive maintenance procedures for insulation systems in industrial facilities.

Preventive maintenance is crucial for ensuring the longevity and effectiveness of insulation systems in industrial facilities. Here are some key procedures:

- Regular inspections: Inspect insulation for any signs of damage, moisture penetration, or deterioration.

- Cleaning: Remove dust, debris, and contaminants that can reduce insulation effectiveness.

- Periodic testing: Conduct insulation resistance tests to monitor its integrity and identify potential issues.

- Repairs: Promptly repair any damaged or compromised insulation to maintain system performance.

7. How do you diagnose and troubleshoot common insulation problems?

Identifying and resolving insulation problems requires a systematic approach:

- Inspect for visible signs: Check for tears, punctures, or moisture damage that may indicate compromised insulation.

- Test insulation resistance: Use a megohmmeter or insulation resistance tester to measure the resistance and identify areas with potential issues.

- Use thermal imaging: Thermal imaging can reveal temperature variations that indicate insulation gaps or deficiencies.

8. What are the best practices for handling and storing insulation materials in a warehouse?

Proper handling and storage of insulation materials are essential to maintain their integrity and performance:

- Protect from moisture: Store insulation in a dry, covered location to prevent moisture absorption.

- Avoid compression: Do not stack insulation materials on top of each other, as this can compress them and reduce their effectiveness.

- Use proper equipment: Use forklifts or other equipment designed for handling insulation materials to avoid damage.

9. How do you stay updated with the latest industry regulations and best practices for insulation installation and maintenance?

- Attend industry conferences and workshops: Engage with professionals and experts to learn about new technologies and best practices.

- Read trade publications and journals: Stay abreast of the latest advancements and industry trends through industry-specific literature.

- Participate in online forums and discussions: Connect with other insulation professionals to exchange information and share experiences.

10. How do you ensure quality control when installing and maintaining insulation systems?

Maintaining quality control is crucial to deliver effective and durable insulation systems:

- Follow manufacturer’s instructions: Adhere to the manufacturer’s guidelines for proper installation and maintenance practices.

- Inspect materials and workmanship: Regularly inspect insulation materials and the installation process to identify any deviations from specifications.

- Test and verify performance: Conduct performance tests, such as thermal imaging or insulation resistance testing, to ensure the system meets the desired standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanic Insulator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanic Insulator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mechanic Insulators install and maintain insulation, refractory, and protective coatings in industrial, commercial, and residential buildings.

1. Install and Maintain Insulation

Insulators install insulation in walls, ceilings, floors, and roofs to improve the thermal efficiency of buildings and reduce energy costs.

- Choose the appropriate insulation materials and installation methods for different types of buildings and applications.

- Install insulation in accordance with building codes and manufacturer’s specifications.

2. Install and Maintain Refractory Materials

Refractory materials are used to line furnaces, boilers, and other high-temperature applications to protect them from damage.

- Install refractory materials in accordance with building codes and manufacturer’s specifications.

- Repair or replace damaged refractory materials.

3. Install and Maintain Protective Coatings

Protective coatings are used to protect surfaces from corrosion, abrasion, and other environmental hazards.

- Apply protective coatings in accordance with building codes and manufacturer’s specifications.

- Inspect and repair protective coatings as needed.

4. Other Responsibilities

In addition to the above, Mechanic Insulators may also perform other tasks, such as:

- Assisting with the installation of mechanical equipment.

- Insulating pipes and ducts.

- Inspecting insulation and refractory materials for damage.

Interview Tips

To prepare for an interview for a Mechanic Insulator position, it is important to:

1. Research the Company and Position

Learn about the company’s history, culture, and products or services. Research the specific Mechanic Insulator position you are applying for to understand the key responsibilities and qualifications.

- Visit the company’s website.

- Read online reviews.

- Talk to people who work at the company.

2. Practice Your Answers to Common Interview Questions

Some common interview questions for Mechanic Insulators include:

- Tell me about your experience installing and maintaining insulation.

- What are the different types of refractory materials and when are they used?

- How do you apply protective coatings?

- What are the safety precautions that you must take when working with insulation and refractory materials?

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company. Some good questions to ask include:

- What are the biggest challenges that you face in your department?

- What is the company’s safety record?

- What are the opportunities for advancement within the company?

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and comfortable shoes.

5. Be Punctual

Arrive on time for your interview. Being punctual shows that you are respectful of the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mechanic Insulator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!