Feeling lost in a sea of interview questions? Landed that dream interview for Mechanic/Welder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mechanic/Welder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

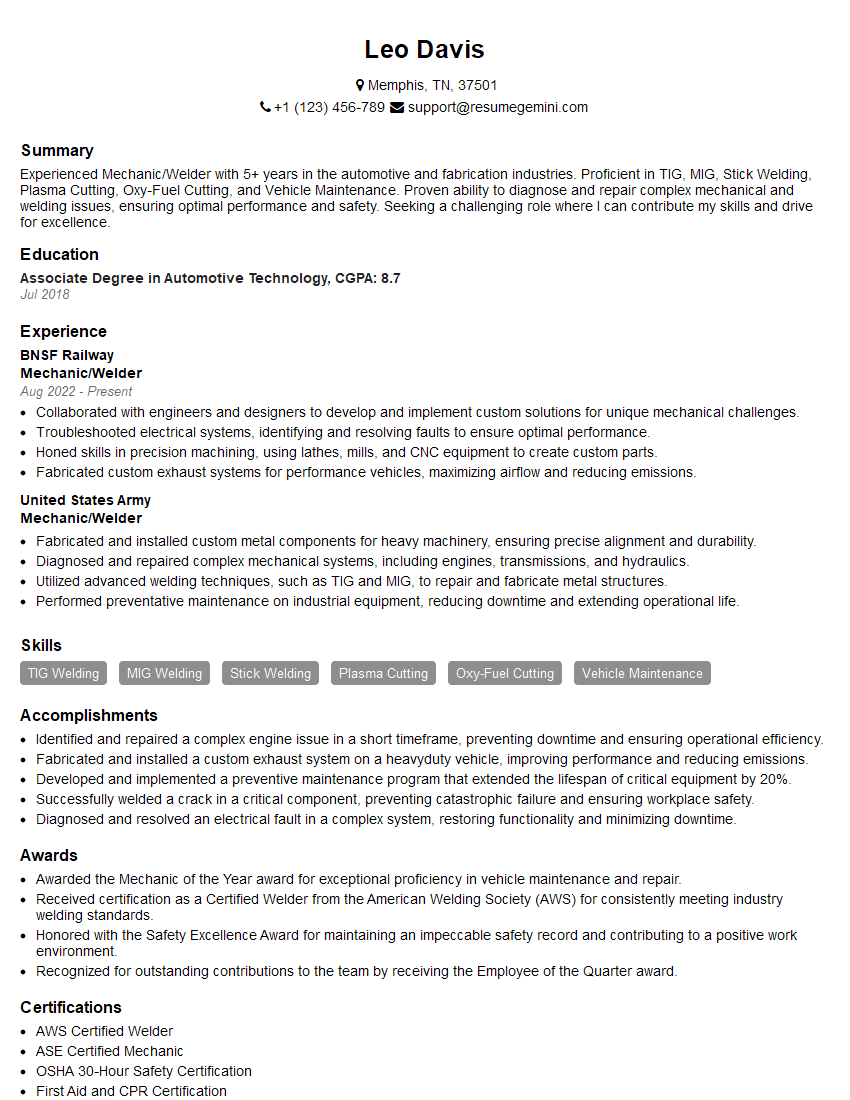

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanic/Welder

1. Describe the steps involved in troubleshooting a faulty engine?

To troubleshoot a faulty engine, I follow these steps:

- Inspect the engine for any visible damage or leaks.

- Check the fuel system for any blockages or leaks.

- Inspect the ignition system for any loose connections or faulty components.

- Use a diagnostic tool to identify any error codes.

- Refer to the manufacturer’s guidelines for further troubleshooting steps.

2. Explain the different types of welding processes and their applications?

Arc Welding

- Used for joining metals using an electric arc.

- Applications: Structural fabrication, pressure vessels, shipbuilding.

MIG Welding

- Uses a shielding gas to protect the weld from contamination.

- Applications: Automotive, construction, aerospace.

TIG Welding

- Uses a tungsten electrode and a shielding gas to create a clean, high-quality weld.

- Applications: Aerospace, medical devices, food processing equipment.

3. What are the safety precautions to consider when working with welding equipment?

When working with welding equipment, I strictly adhere to the following safety precautions:

- Wear appropriate protective gear, including gloves, welding helmet, and flame-resistant clothing.

- Ensure proper ventilation to avoid inhaling welding fumes.

- Inspect equipment regularly for any damage or defects.

- Never weld in flammable or explosive environments.

- Be aware of the potential hazards of electric shock and arc flash.

4. How do you ensure the quality of your welding work?

To ensure the quality of my welding work, I follow these practices:

- Thoroughly prepare the surfaces to be welded by cleaning and removing any contaminants.

- Select the appropriate welding process and materials for the specific application.

- Meticulously follow the welding parameters and procedures.

- Inspect the welds visually and, if necessary, perform non-destructive testing to verify their integrity.

- Continuously seek feedback and training to enhance my skills and stay up-to-date with industry best practices.

5. Describe a complex welding project you have undertaken and the challenges you faced?

In my previous role, I was tasked with welding a large-diameter pressure vessel. The challenges encountered included:

- Ensuring precise alignment and fit-up of the components.

- Minimizing distortion and maintaining the vessel’s structural integrity.

- Working within strict quality control specifications and meeting ASME welding codes.

- Overcoming the challenges of working in a confined space.

Through careful planning, proper technique, and collaboration with skilled colleagues, I successfully completed the project, meeting all quality and safety requirements.

6. What is your approach to identifying and resolving mechanical problems in vehicles?

My approach to identifying and resolving mechanical problems in vehicles involves the following steps:

- Gather information from the customer, including symptoms and vehicle history.

- Perform a thorough visual inspection of the vehicle, paying attention to any unusual noises or leaks.

- Use diagnostic tools, such as scanners and multimeters, to identify potential faults.

- Consult technical documentation and reference materials to determine the most likely causes of the problems.

- Develop and implement a repair plan, prioritizing safety and cost-effectiveness.

7. How do you maintain and update your knowledge and skills in the field of mechanics/welding?

To stay up-to-date with advancements in the field of mechanics/welding, I engage in the following practices:

- Attend industry conferences, workshops, and training sessions.

- Read technical publications, journals, and online resources.

- Seek guidance and mentorship from experienced professionals.

- Obtain certifications and licenses to demonstrate my proficiency.

- Actively participate in industry forums and discussion groups.

8. Describe a situation where you had to prioritize multiple tasks and manage your time effectively?

In a previous role, I was responsible for maintaining a fleet of vehicles in a busy workshop. During a particularly demanding period, I faced the challenge of handling multiple urgent repairs simultaneously.

- I assessed the urgency and potential impact of each repair request.

- Prioritized tasks based on safety and customer needs.

- Effectively delegated responsibilities to my team members.

- Optimized my workflow by streamlining processes and minimizing downtime.

Through effective time management and communication, I successfully completed all repairs within the required timeframes, ensuring minimal disruption to our operations.

9. How do you ensure that your work meets safety regulations and standards?

Ensuring adherence to safety regulations and standards is paramount in my work:

- I am thoroughly familiar with relevant safety codes and industry best practices.

- I regularly inspect my equipment and ensure it is in good working order.

- I wear appropriate personal protective equipment at all times.

- I follow established safety protocols and procedures.

- I am proactive in identifying potential hazards and implementing measures to mitigate risks.

10. What are your motivations for pursuing a career in mechanics/welding?

My passion for mechanics/welding stems from a deep fascination with the intricate workings of machines and the satisfaction of solving complex problems.

- I am intrigued by the challenge of diagnosing and repairing vehicles and equipment.

- I enjoy the hands-on nature of the work and the opportunity to apply my skills in a practical setting.

- I am driven by the desire to contribute to the safety and reliability of our infrastructure and transportation systems.

- I believe that my technical abilities and dedication make me a valuable asset to any organization in this field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanic/Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanic/Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Mechanic/Welder, you will have a multifaceted role involving mechanical repairs, welding tasks, and maintenance activities. Your responsibilities will encompass:

1. Mechanical Repairs

You will diagnose and repair various mechanical systems, including engines, transmissions, brakes, and electrical components.

- Inspect and troubleshoot mechanical systems to identify malfunctions.

- Perform repairs and replacements as necessary, ensuring functionality and safety.

- Maintain accurate records of repairs and preventive maintenance.

2. Welding Operations

You will perform a range of welding tasks using different techniques to fabricate, repair, and assemble metal components.

- Interpret welding blueprints and specifications to determine appropriate techniques.

- Operate welding equipment, such as arc welders, MIG welders, and TIG welders, to create strong and durable welds.

- Ensure compliance with safety regulations and industry standards.

3. Equipment Maintenance

You will maintain and repair various equipment and machinery to ensure optimal performance and longevity.

- Conduct preventive maintenance checks and inspections to identify potential issues.

- Perform repairs and replacements on equipment, such as engines, generators, pumps, and compressors.

- Monitor equipment performance and provide recommendations for upgrades or modifications.

4. Safety Compliance

You will prioritize safety in all aspects of your work, adhering to established regulations and procedures.

- Follow OSHA and industry safety guidelines to prevent accidents and injuries.

- Wear appropriate personal protective equipment (PPE) and follow proper handling techniques.

- Maintain a clean and organized work environment to minimize hazards.

Interview Tips

To ace your interview for a Mechanic/Welder position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This knowledge will demonstrate your interest and enthusiasm for the position.

- Visit the company website, read industry news, and attend industry events.

- Highlight your research during the interview to show your preparedness.

2. Emphasize Your Skills and Experience

Showcase your technical abilities, including your welding techniques, mechanical repair experience, and safety knowledge.

- Provide specific examples of projects you have worked on and the challenges you overcame.

- Quantify your accomplishments whenever possible, such as the number of repairs completed or the percentage improvement in equipment performance.

3. Demonstrate Problem-Solving Abilities

Interviewers will be interested in your ability to analyze problems and find solutions. Share examples where you diagnosed and repaired complex mechanical or welding issues.

- Walk the interviewer through your problem-solving process, explaining the steps you took to identify and resolve the problem.

- Emphasize your analytical and critical thinking skills.

4. Highlight Your Safety Mindset

Safety is paramount in this role. Emphasize your commitment to following safety protocols and maintaining a safe work environment.

- Describe your adherence to industry regulations and the specific safety measures you implement in your work.

- Explain how you promote a culture of safety in your team.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Mechanic/Welder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Mechanic/Welder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.