Are you gearing up for a career in Mechanical Assembly Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mechanical Assembly Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

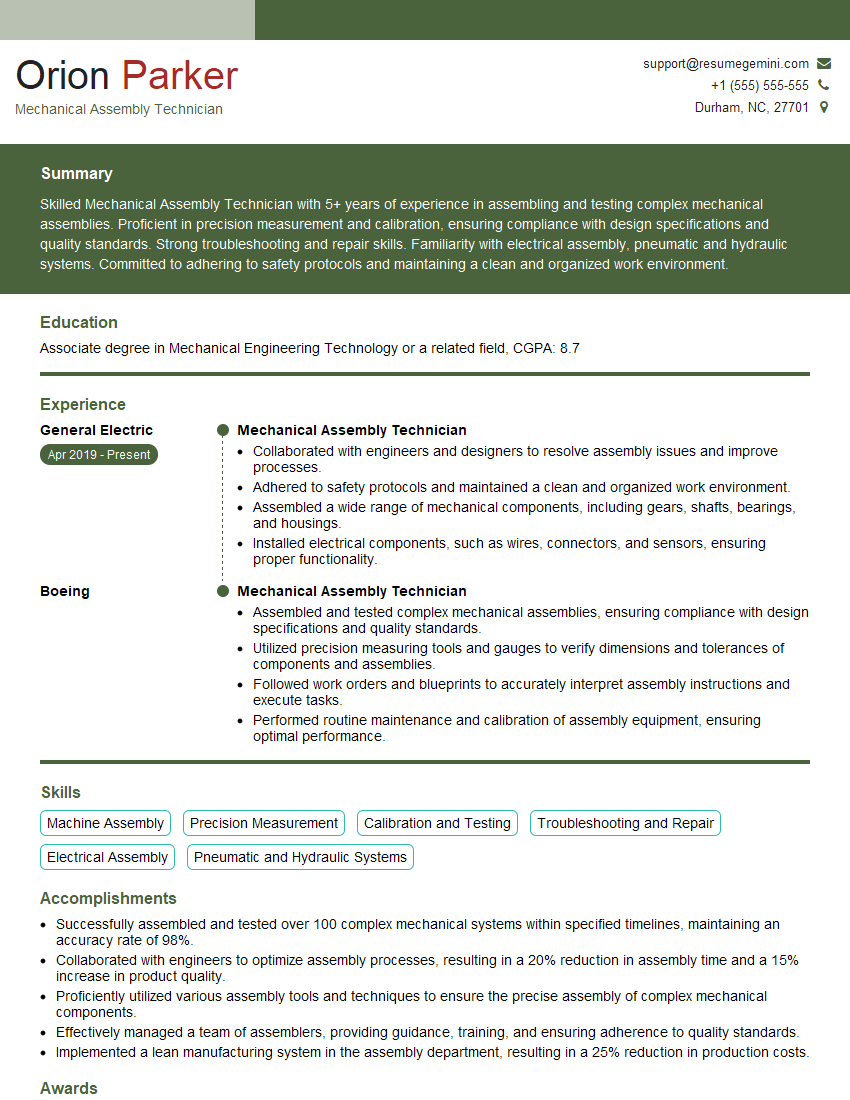

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanical Assembly Technician

1. How would you measure the bore of a cylinder?

To measure the bore of a cylinder, I would use a bore gauge. A bore gauge is a precision measuring tool that consists of a cylindrical plug with a micrometer attached to it. The plug is inserted into the bore and the micrometer is used to measure the diameter of the bore.

2. How would you determine the pitch of a screw thread?

To determine the pitch of a screw thread, I would use a thread pitch gauge. A thread pitch gauge is a tool that has a series of blades with different pitches. The blades are inserted into the screw thread and the blade that fits the thread the best will indicate the pitch of the screw.

3. How would you calculate the torque required to tighten a bolt?

To calculate the torque required to tighten a bolt, I would use the following formula: T = K * F * d “` where: * T is the torque in newton-meters (N-m) * K is the coefficient of friction * F is the force applied to the bolt in newtons (N) * d is the diameter of the bolt in meters (m)

The coefficient of friction is a dimensionless number that depends on the materials of the bolt and the nut. I would use a table of coefficients of friction to find the appropriate value for the materials I am using.

4. How would you assemble a gear train?

To assemble a gear train, I would first identify the gears that I need to use. I would then use a gear puller to remove the gears from their shafts. I would then clean the gears and the shafts. I would then apply a thin layer of grease to the gears and the shafts. I would then slide the gears onto the shafts. I would then use a torque wrench to tighten the bolts that hold the gears in place.

5. How would you troubleshoot a hydraulic system?

To troubleshoot a hydraulic system, I would first check the fluid level. I would then check the pressure in the system. I would then check the flow rate of the fluid. I would then check the temperature of the fluid. I would then check the condition of the hoses and fittings. I would then check the condition of the pump. I would then check the condition of the valves. I would then check the condition of the cylinders.

6. How would you maintain a pneumatic system?

To maintain a pneumatic system, I would first check the air pressure. I would then check the condition of the hoses and fittings. I would then check the condition of the compressor. I would then check the condition of the valves. I would then check the condition of the cylinders. I would then check the condition of the filters. I would then check the condition of the lubricators.

7. How would you interpret a mechanical drawing?

To interpret a mechanical drawing, I would first identify the title block. The title block contains information about the drawing, such as the name of the part, the scale of the drawing, and the date of the drawing. I would then identify the views of the part. The views of the part show the part from different angles. I would then identify the dimensions of the part. The dimensions of the part tell me the size of the part.

8. How would you use a micrometer?

To use a micrometer, I would first clean the anvil and the spindle. I would then close the micrometer and set the zero point. I would then open the micrometer and place the object to be measured between the anvil and the spindle. I would then close the micrometer until the object is snugly held. I would then read the measurement on the micrometer scale.

9. How would you use a vernier caliper?

To use a vernier caliper, I would first clean the jaws and the beam. I would then close the caliper and set the zero point. I would then open the caliper and place the object to be measured between the jaws. I would then close the caliper until the object is snugly held. I would then read the measurement on the caliper scale. I would then read the measurement on the vernier scale.

10. What are the different types of fasteners?

There are many different types of fasteners, including:

- Bolts

- Nuts

- Screws

- Washers

- Pins

- Rivets

- Retaining rings

- Clamps

- Velcro

- Glue

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanical Assembly Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanical Assembly Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mechanical Assembly Technicians are responsible for assembling and testing mechanical components and systems according to specifications.

1. Assembly and Installation

Assemble mechanical components, subassemblies, and systems following blueprints, diagrams, and specifications.

- Use hand tools, power tools, and specialized equipment to assemble and install components.

- Ensure that all components are properly aligned and secured.

2. Testing and Inspection

Test assembled components and systems to ensure they meet specifications.

- Conduct functional tests, performance tests, and quality control inspections.

- Identify and correct any defects or malfunctions.

3. Maintenance and Repair

Perform preventive maintenance and repairs on mechanical equipment.

- Inspect equipment for wear, damage, or misalignment.

- Replace or repair worn or damaged parts.

4. Troubleshooting and Problem Solving

Troubleshoot and resolve mechanical problems.

- Identify the root cause of problems and develop solutions.

- Make adjustments or modifications to equipment to improve performance.

Interview Tips

To ace an interview for a Mechanical Assembly Technician position, preparation is key.

1. Research the Company and Position

Learn about the company’s products, services, and culture. Research the specific position you are applying for and the responsibilities it entails.

- Visit the company’s website and LinkedIn page.

- Read industry news and articles to stay up-to-date on the latest trends.

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to the job description. Use specific examples to demonstrate your skills and experience in mechanical assembly.

- Quantify your accomplishments whenever possible.

- Use action verbs and technical terms to describe your work experience.

3. Prepare for Technical Questions

Be prepared to answer technical questions about mechanical assembly, including blueprint reading, tool operation, and troubleshooting techniques.

- Review basic mechanical engineering principles and formulas.

- Practice using common assembly tools and equipment.

4. Show Your Enthusiasm

Convey your passion for mechanical assembly during the interview.

- Speak confidently about your abilities and experience.

- Ask thoughtful questions about the company and the position.

Next Step:

Now that you’re armed with the knowledge of Mechanical Assembly Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mechanical Assembly Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini