Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mechanical Designer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

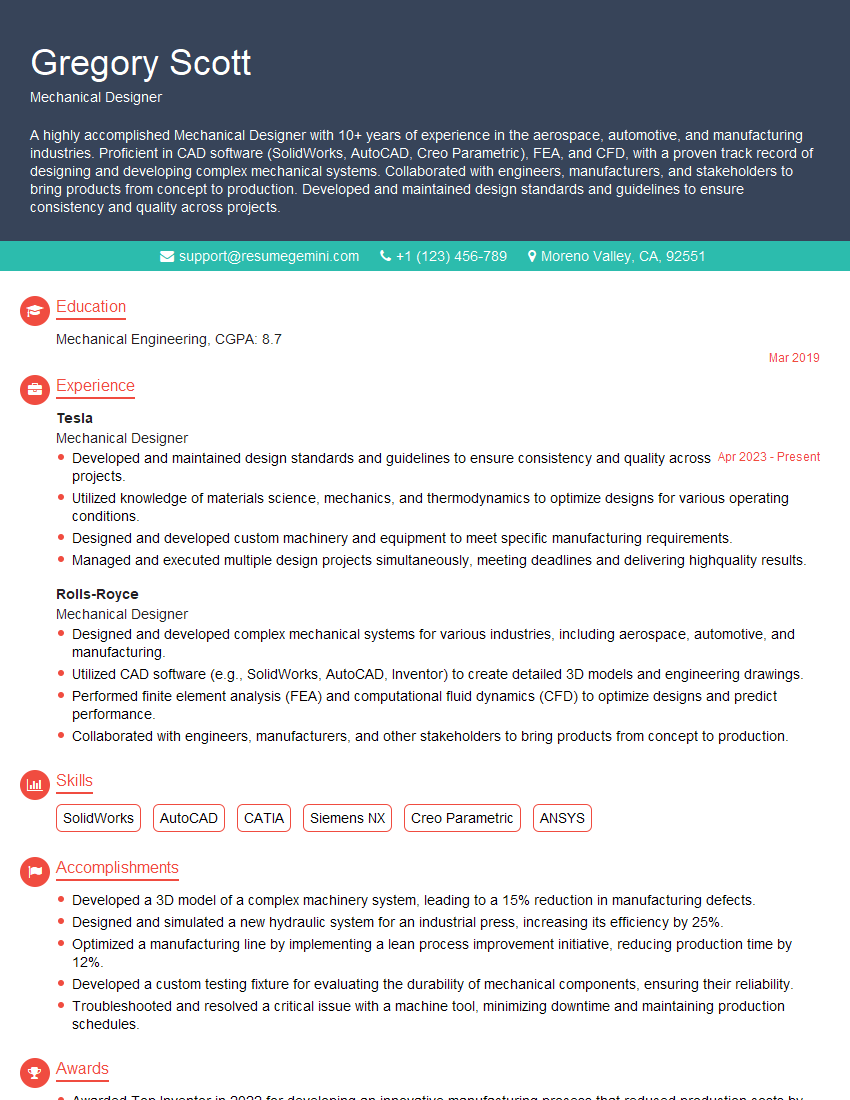

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanical Designer

1. How would you approach the design of a complex mechanical assembly, such as a gearbox or engine?

Explain the design process from initial concept to final product, including key considerations and tools used.

- Begin with a thorough understanding of the design requirements and specifications.

- Brainstorm and sketch out multiple concept designs that meet the requirements.

- Use computer-aided design (CAD) software to create detailed 3D models of the design.

- Analyze the models using simulation and finite element analysis (FEA) to verify their performance and identify any potential issues.

- Prototype and test the design to ensure it meets the requirements before finalizing the design.

2. Describe your experience with using CAD software. What specific software packages are you proficient in?

CAD Software Proficiency

- SolidWorks

- AutoCAD

- Creo Parametric

Experience with CAD Software

- Designed and modeled complex mechanical assemblies.

- Created detailed 3D models and 2D drawings.

- Utilized simulation and FEA to analyze and optimize designs.

3. How do you stay up-to-date on the latest advancements in mechanical design technology?

Explain methods used to keep up with industry trends, new software, and best practices.

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and communities.

- Take continuing education courses.

4. What are the key differences between additive and subtractive manufacturing processes?

Provide a detailed comparison of the two technologies, including their advantages and limitations.

- Additive manufacturing (3D printing):

- Advantages:

- Can create complex geometries that are difficult or impossible to manufacture using subtractive methods.

- Reduces material waste.

- Disadvantages:

- Can be slower and more expensive than subtractive methods.

- May have limitations on material properties.

- Subtractive manufacturing (CNC machining):

- Advantages:

- Can produce high-precision parts with tight tolerances.

- Can be faster and more cost-effective for large production runs.

- Disadvantages:

- Can create more material waste.

- May be limited in the complexity of geometries that can be manufactured.

5. How do you ensure the reliability and durability of your designs?

Describe the methods and techniques used to analyze and optimize designs for performance and longevity.

- Use simulation and FEA to analyze stress, strain, and other factors that can affect reliability and durability.

- Conduct physical testing to validate the performance of the design.

- Apply design principles and best practices to minimize potential failure points.

- Consider factors such as material selection, manufacturing tolerances, and environmental conditions.

6. How do you collaborate with other engineers and stakeholders during the design process?

Explain the importance of communication and teamwork in the design process.

- Attend regular design review meetings to discuss progress and identify issues.

- Use collaboration tools such as shared design documents and online forums.

- Seek feedback and input from other engineers and stakeholders throughout the design process.

- Resolve conflicts and ensure that all team members are on the same page.

7. Describe your experience with design for manufacturability (DFM).

Explain how you consider manufacturing constraints and optimize designs for ease of production.

- Consider factors such as material availability, manufacturing processes, and assembly techniques.

- Design parts that are easy to machine, assemble, and test.

- Minimize the number of components and assembly steps.

- Use standard components and off-the-shelf parts whenever possible.

8. How do you manage design changes and revisions?

Explain the process for tracking, implementing, and documenting design changes.

- Use a change management system to track and document all design changes.

- Communicate design changes to all affected parties in a timely manner.

- Review and approve design changes before they are implemented.

- Update design documentation and drawings to reflect any changes.

9. Describe your experience with project management in the context of mechanical design.

Explain how you plan, execute, and track design projects.

- Set clear project goals and objectives.

- Develop a detailed project plan that includes timelines, milestones, and resources.

- Assign tasks and responsibilities to team members.

- Monitor project progress and identify risks or issues.

- Communicate project updates to stakeholders.

10. What are your strengths and weaknesses as a mechanical designer?

Provide a balanced and honest assessment of your skills and areas for improvement.

Strengths:- Strong understanding of mechanical design principles.

- Proficient in CAD software and simulation tools.

- Excellent problem-solving and analytical skills.

- Ability to work independently and as part of a team.

- Limited experience with certain advanced design techniques.

- Can sometimes be overly perfectionist and spend too much time on details.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanical Designer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanical Designer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mechanical designers play a vital role in product development, leveraging their expertise in engineering principles and computer-aided design (CAD) software to create detailed plans for machines, components, and systems.

1. Design and Development

Collaborate with product development teams to create detailed designs that meet customer needs and specifications.

- Develop concept designs, using sketching, CAD software, and engineering analysis tools.

- Conduct performance testing, prototype fabrication, and analysis to validate designs.

2. CAD and 3D Modeling

Create accurate and detailed CAD models using industry-standard software.

- Generate 3D models, assemblies, and detailed drawings for manufacturing.

- Develop documentation, technical drawings, and specifications for production.

3. Mechanical Analysis

Apply engineering principles to analyze and optimize designs for performance.

- Conduct stress, thermal, and dynamic analysis to ensure designs meet industry standards.

- Review and approve designs to ensure they comply with quality and safety regulations.

4. Manufacturing Support

Provide technical support to manufacturing teams during production.

- Liaise with manufacturers to resolve production issues and ensure smooth transitions.

- Troubleshoot and provide solutions for manufacturing challenges.

Interview Tips

To ace the interview for a mechanical design role, it’s essential to prepare thoroughly and showcase your skills and experience effectively.

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and culture. Understand the specific requirements of the role you’re applying for and tailor your responses accordingly.

2. Highlight Your Technical Skills

Emphasize your proficiency in CAD software, analysis tools, and engineering principles. Provide concrete examples of projects where you applied these skills successfully.

3. Showcase Your Design Process

Explain your approach to mechanical design, from concept development to production support. Use the STAR method (Situation, Task, Action, Result) to illustrate your experiences.

4. Prepare for Industry-Specific Questions

Research the industry trends and best practices related to mechanical design. Be prepared to discuss your knowledge of materials, manufacturing processes, and quality standards.

5. Practice Answering Common Interview Questions

Prepare for standard interview questions such as “Tell me about your experience” and “Why are you interested in this role?” Rehearse your answers to deliver them clearly and confidently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mechanical Designer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!