Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Mechanical Electrical Plumbing Supervisor (MEP Supervisor) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

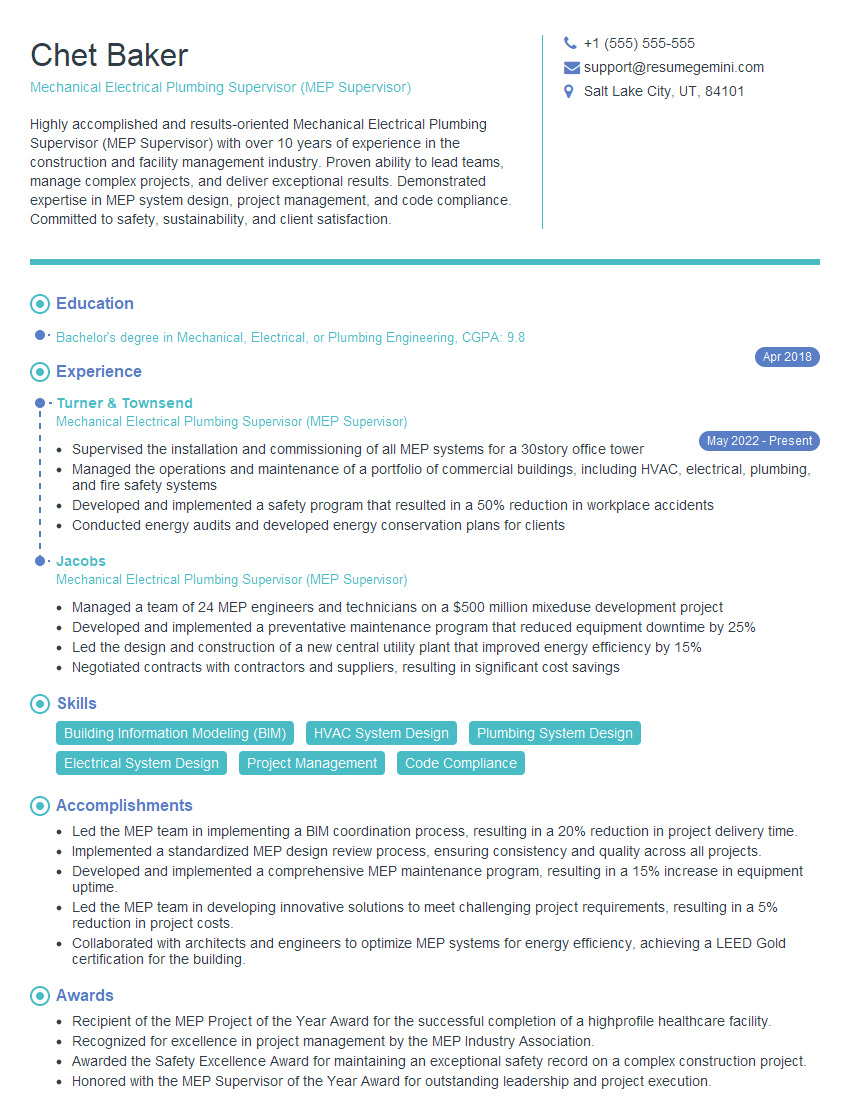

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanical Electrical Plumbing Supervisor (MEP Supervisor)

1. What is the difference between a balanced and unbalanced electrical system?

In a balanced system, the loads are evenly distributed across the three phases, while in an unbalanced system, the loads are not evenly distributed. This can cause problems with voltage regulation and power factor. Here are some of the key differences between balanced and unbalanced electrical systems:

- Balanced systems have equal voltages on all three phases.

- Balanced systems have equal currents on all three phases.

- Balanced systems have a power factor of 1.

- Unbalanced systems have unequal voltages on the three phases.

- Unbalanced systems have unequal currents on the three phases.

- Unbalanced systems have a power factor less than 1.

2. What are the different types of electrical loads?

Resistive loads

- Resistive loads are the most common type of electrical load. They include things like incandescent light bulbs, electric heaters, and toasters.

- Resistive loads draw a constant current from the power source.

Inductive loads

- Inductive loads include things like motors, transformers, and inductors.

- Inductive loads draw a current that lags the voltage.

- Inductive loads can cause power factor problems.

Capacitive loads

- Capacitive loads include things like capacitors and power factor correction capacitors.

- Capacitive loads draw a current that leads the voltage.

- Capacitive loads can help to improve power factor.

3. How can you improve the power factor of an electrical system?

There are several ways to improve the power factor of an electrical system, including:

- Installing power factor correction capacitors.

- Using synchronous motors.

- Using variable frequency drives.

- Reducing the number of inductive loads.

4. What are the different types of HVAC systems?

- Split systems: Split systems consist of an outdoor unit and an indoor unit. The outdoor unit houses the compressor and condenser, while the indoor unit houses the evaporator and blower.

- Packaged systems: Packaged systems combine the outdoor and indoor units into a single unit. This type of system is often used in smaller buildings.

- Variable refrigerant flow (VRF) systems: VRF systems use a variable refrigerant flow to control the temperature in different zones of a building. This type of system is often used in larger buildings.

5. What are the different types of plumbing systems?

- Water supply systems: Water supply systems provide water to fixtures and appliances throughout a building. These systems typically include a water meter, a pressure regulator, and a water heater.

- Drain-waste-vent (DWV) systems: DWV systems remove wastewater from fixtures and appliances throughout a building. These systems typically include a main drain, vent pipes, and traps.

- Gas piping systems: Gas piping systems provide gas to appliances throughout a building. These systems typically include a gas meter, a pressure regulator, and a gas line.

6. What are the most common problems with MEP systems?

- Electrical problems: Electrical problems can include things like power outages, voltage fluctuations, and ground faults.

- HVAC problems: HVAC problems can include things like heating or cooling problems, refrigerant leaks, and air quality problems.

- Plumbing problems: Plumbing problems can include things like leaks, clogs, and backflows.

7. How can you prevent problems with MEP systems?

There are several things you can do to prevent problems with MEP systems, including:

- Regular maintenance: Regular maintenance is the best way to prevent problems with MEP systems. This includes things like inspecting equipment, cleaning filters, and checking for leaks.

- Proper installation: MEP systems should be properly installed by qualified professionals. This will help to ensure that the systems are operating efficiently and safely.

- Training: Employees should be trained on how to operate and maintain MEP systems. This will help to prevent problems and ensure that the systems are operating safely.

8. What is your experience with MEP systems?

I have over 10 years of experience with MEP systems. I have worked on a variety of projects, including commercial buildings, residential buildings, and industrial facilities. I have experience with all aspects of MEP systems, including design, installation, and maintenance.

9. What are your strengths and weaknesses as an MEP Supervisor?

Strengths

- I am a highly motivated and results-oriented individual.

- I have a strong understanding of MEP systems.

- I have excellent communication and interpersonal skills.

- I am a team player and I am able to work independently.

Weaknesses

- I am sometimes too detail-oriented.

- I can be a bit of a perfectionist.

10. Why are you interested in this job?

I am interested in this job because it is a great opportunity to use my skills and experience to make a difference in the lives of others. I am passionate about MEP systems and I believe that I can use my knowledge and expertise to help ensure that buildings are safe, comfortable, and efficient.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanical Electrical Plumbing Supervisor (MEP Supervisor).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanical Electrical Plumbing Supervisor (MEP Supervisor)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Mechanical Electrical Plumbing Supervisor (MEP Supervisor) is a critical role within a construction or engineering project. Key responsibilities include:

1. Overseeing MEP Systems

The MEP Supervisor is responsible for the installation, maintenance, and repair of all mechanical, electrical, and plumbing systems within a building. This includes HVAC systems, plumbing fixtures, electrical wiring, and fire protection systems.

2. Managing MEP Subcontractors

The MEP Supervisor works closely with MEP subcontractors to ensure that all work is completed on time, within budget, and to the required specifications. They must be able to coordinate and manage multiple contractors, including plumbers, electricians, and HVAC technicians.

3. Coordinating with Other Project Stakeholders

The MEP Supervisor must be able to effectively communicate and coordinate with other project stakeholders, such as the project manager, architect, and engineer. They must be able to provide input on MEP design and ensure that the MEP systems are compatible with the overall project design.

4. Ensuring Compliance with Building Codes and Regulations

The MEP Supervisor is responsible for ensuring that all MEP systems are installed in accordance with building codes and regulations. They must be familiar with the relevant codes and ensure that all work is completed to the required standards.

Interview Tips

To ace the interview for an MEP Supervisor position, candidates should:

1. Prepare for Technical Questions

Candidates should be prepared to answer questions about MEP systems, building codes, and construction practices. They should be able to demonstrate a strong understanding of the technical aspects of the role.

- Example Question: Describe the different types of HVAC systems and their applications.

- Example Answer: There are four main types of HVAC systems: central systems, packaged systems, split systems, and mini-split systems. Central systems are located outside of the conditioned space and distribute air through ducts. Packaged systems are also located outside of the conditioned space but combine the heating and cooling components into a single unit. Split systems have an outdoor unit and an indoor unit that are connected by refrigerant lines. Mini-split systems are similar to split systems, but they are designed for smaller spaces and have multiple indoor units.

2. Highlight Management and Leadership Skills

MEP Supervisors need to be able to effectively manage and lead a team of contractors. They should be able to motivate and inspire their team and ensure that all work is completed on time and to the required standards.

- Example Question: Describe a time when you successfully managed a team of contractors on a complex project.

- Example Answer: On a recent project, I was responsible for managing a team of contractors to install the mechanical, electrical, and plumbing systems for a new hospital. The project was complex and had a tight deadline. I was able to successfully manage the team and ensure that all work was completed on time and to the required standards. I did this by setting clear expectations, providing regular feedback, and recognizing the team’s accomplishments.

3. Research the Company and Project

Candidates should take the time to research the company and the specific project for which they are applying. This will help them to understand the company’s culture and the project’s requirements. They should be prepared to discuss how their skills and experience can benefit the company and the project.

4. Practice Answering Common Interview Questions

Candidates should practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” They should also be prepared to discuss their strengths, weaknesses, and career goals.

- Example Question: Why are you interested in this position?

- Example Answer: I am interested in this position because I am passionate about the MEP industry and I have a strong track record of success in managing MEP projects. I am also confident that my skills and experience would be a valuable asset to your team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mechanical Electrical Plumbing Supervisor (MEP Supervisor) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!