Are you gearing up for a career in Mechanical Maintenance Supervisor? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Mechanical Maintenance Supervisor and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

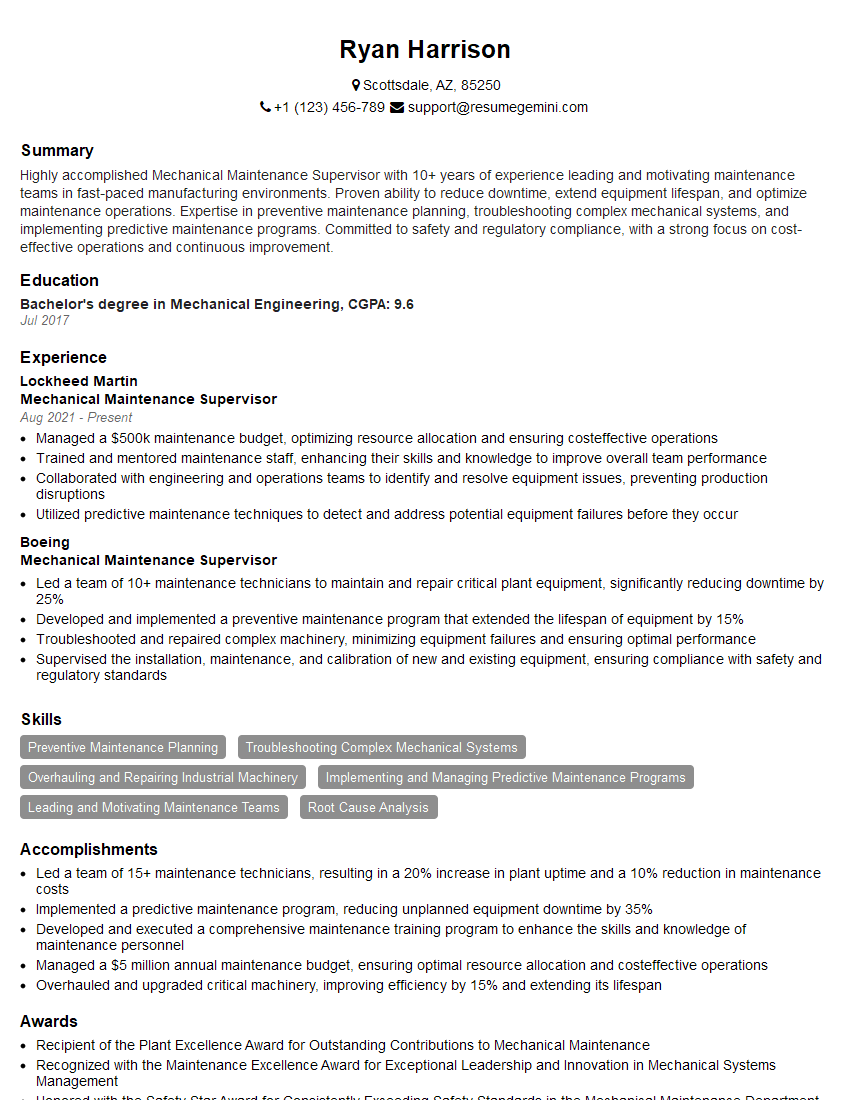

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanical Maintenance Supervisor

1. How would you approach a situation where a critical piece of equipment has failed and needs to be repaired as quickly as possible?

In such a situation, I would:

- Identify the problem quickly and accurately using proper diagnostic methods.

- Prioritize the repair based on the equipment’s criticality and the potential impact of the downtime.

- Gather the necessary resources, including spare parts, tools, and personnel.

- Execute the repair efficiently and effectively, following safety protocols and technical specifications.

- Test the repaired equipment thoroughly to ensure it is functioning properly.

- Document the repair process and communicate the status to relevant stakeholders.

2. Describe your experience in implementing predictive maintenance strategies. How have they improved the reliability and efficiency of equipment?

Benefits of Predictive Maintenance

- Reduced unplanned downtime.

- Increased equipment life and reliability.

- Improved safety and compliance.

- Optimized maintenance schedules.

- Enhanced energy efficiency.

Implementation Process

- Baseline data collection and analysis.

- Condition monitoring technologies and sensors.

- Data analysis and diagnostics.

- Maintenance planning and optimization.

- Performance evaluation and continuous improvement.

3. How do you ensure the health and safety of your team while performing maintenance tasks?

I prioritize the health and safety of my team by:

- Conducting regular safety training and drills.

- Enforcing proper use of personal protective equipment (PPE).

- Establishing safe work procedures and protocols.

- Inspecting tools and equipment regularly.

- Promoting a culture of safety consciousness and reporting any hazardous conditions.

- Investigating accidents and incidents thoroughly and implementing corrective actions.

4. How would you optimize maintenance schedules to minimize downtime and maximize equipment availability?

To optimize maintenance schedules, I would:

- Implement preventive maintenance and lubrication programs.

- Use reliability-centered maintenance (RCM) principles to identify and prioritize tasks.

- Monitor equipment performance and usage data to determine optimal maintenance intervals.

- Schedule maintenance activities during low-production periods or downtime.

- Incorporate predictive maintenance techniques to detect potential issues early.

- Collaborate with production teams to plan maintenance activities that minimize disruption.

5. Describe your experience in managing a team of maintenance technicians. How do you motivate and empower them?

In managing a team of maintenance technicians, I:

- Establish clear roles, responsibilities, and expectations.

- Provide ongoing training and development opportunities.

- Foster a positive and collaborative work environment.

- Recognize and reward exceptional performance.

- Empower technicians to make decisions and take ownership of their work.

- Encourage teamwork and cross-training.

- Provide regular feedback and support to help technicians grow professionally.

6. How do you stay up-to-date on the latest maintenance technologies and best practices?

I stay up-to-date on maintenance technologies and best practices by:

- Attending industry conferences and seminars.

- Reading technical journals and publications.

- Participating in online forums and webinars.

- Seeking certifications and continuing education.

- Collaborating with manufacturers and vendors.

- Implementing pilot programs to evaluate new technologies.

7. How do you prioritize maintenance tasks when faced with multiple urgent requests?

When faced with multiple urgent maintenance requests, I prioritize tasks based on the following criteria:

- Safety concerns.

- Impact on production and revenue.

- Equipment criticality.

- Estimated repair time.

- Availability of resources.

- Long-term consequences of deferring maintenance.

8. Describe your approach to managing spare parts inventory. How do you balance cost-effectiveness with ensuring availability?

To manage spare parts inventory effectively, I:

- Maintain an optimized inventory level based on historical usage data and criticality analysis.

- Implement inventory management software to track stock levels and usage.

- Negotiate favorable terms with suppliers to reduce costs while ensuring timely delivery.

- Establish a vendor evaluation process to ensure quality and reliability.

- Conduct regular inventory audits to identify discrepancies and prevent stockouts.

- Collaborate with suppliers to forecast future demand and plan for potential supply chain disruptions.

9. How do you communicate maintenance plans and updates to stakeholders, including management, production, and engineering teams?

I ensure effective communication of maintenance plans and updates to stakeholders by:

- Developing clear and concise documentation.

- Holding regular meetings to discuss maintenance needs and priorities.

- Using online platforms and communication tools to share information.

- Providing timely updates on maintenance progress and any potential delays.

- Responding promptly to inquiries and requests for information.

- Seeking feedback from stakeholders to improve communication effectiveness.

10. Describe your experience with root cause analysis and corrective action implementation. How do you ensure that problems are resolved permanently?

Root Cause Analysis

- Using logical and analytical techniques to identify underlying causes of equipment failures.

- Investigating multiple potential factors, including design, manufacturing, installation, operation, and maintenance.

Corrective Action Implementation

- Developing and implementing effective corrective actions to prevent recurrence of problems.

- Monitoring and evaluating the effectiveness of corrective actions to ensure long-term resolution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanical Maintenance Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanical Maintenance Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Mechanical Maintenance Supervisor plays a key role in overseeing and managing the maintenance and repair of mechanical systems within an organization. Their responsibilities encompass a wide range of tasks, including:

1. Maintenance Management

Supervising and coordinating a team of maintenance technicians

- Scheduling maintenance activities and inspections

- Developing and implementing maintenance plans and procedures

2. Equipment Maintenance

Ensuring the proper maintenance and repair of mechanical equipment

- Diagnosing and troubleshooting equipment failures

- Performing repairs and replacements as needed

3. Inventory Management

Managing the inventory of spare parts and materials

- Ordering and stocking necessary parts

- Tracking inventory levels and ensuring timely replenishment

4. Safety and Compliance

Enforcing safety regulations and ensuring compliance

- Conducting safety inspections and audits

- Providing training and guidance to employees on safety procedures

Interview Tips

Preparing thoroughly for an interview is crucial to making a positive impression and showcasing your qualifications. Here are some tips to help you ace your interview for a Mechanical Maintenance Supervisor position:

1. Research the Company and Position

Familiarize yourself with the company’s industry, size, and recent developments. Understand the specific requirements and responsibilities of the Mechanical Maintenance Supervisor role.

- Visit the company website and social media pages

- Read industry news and articles about the company’s sector

2. Highlight Your Technical Expertise

Emphasize your proficiency in mechanical maintenance principles, equipment troubleshooting, and repair techniques. Provide specific examples from your previous experience that demonstrate your technical abilities.

- Describe a complex maintenance project you successfully managed

- Explain how you implemented a new maintenance procedure that improved efficiency

3. Demonstrate Leadership and Management Skills

Showcase your ability to lead and motivate a team effectively. Discuss your experience in managing maintenance personnel, assigning tasks, and resolving conflicts.

- Share an example of how you motivated your team to achieve a challenging goal

- Describe a situation where you successfully resolved a conflict between team members

4. Emphasize Safety and Compliance

Highlight your commitment to safety and compliance in the workplace. Explain your experience in conducting safety audits, implementing safety programs, and ensuring adherence to regulations.

- Discuss a safety initiative you implemented that improved the safety culture of your previous workplace

- Explain how you stay up-to-date on industry safety standards and best practices

5. Practice Your Answers

Prepare thoughtful and concise answers to common interview questions. Practice delivering your answers confidently and clearly. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

- Anticipate questions about your technical skills, leadership abilities, and safety experience

- Rehearse your answers with a friend or family member

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mechanical Maintenance Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.