Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mechanical Spreader Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mechanical Spreader Operator so you can tailor your answers to impress potential employers.

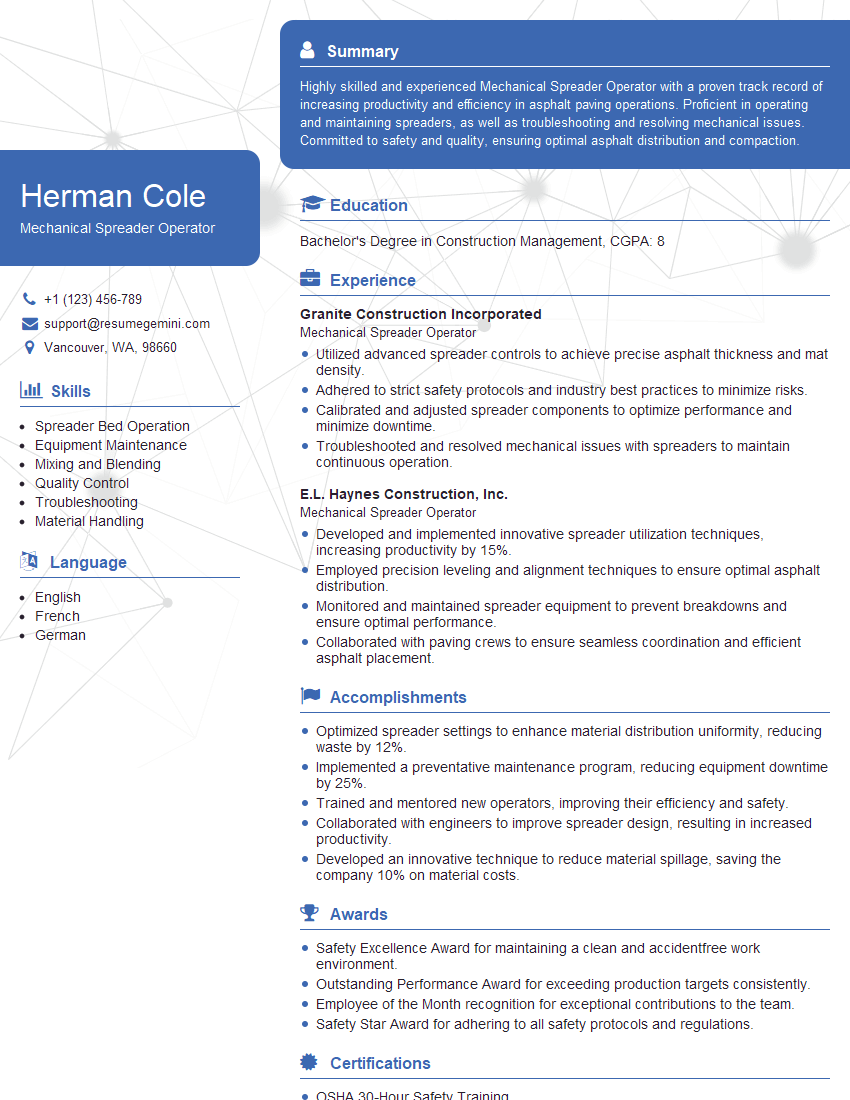

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanical Spreader Operator

1. What are the main responsibilities of a Mechanical Spreader Operator?

As a Mechanical Spreader Operator, my primary responsibilities include:

- Operating mechanical spreaders to apply materials such as asphalt, concrete, or soil evenly onto surfaces

- Controlling the spreader’s speed, width, and depth of application

2. How do you ensure the quality of the applied materials?

Maintaining Equipment

- Regularly inspect and maintain the spreader to ensure its proper functioning

- Calibrate the spreader to achieve precise application rates and dimensions

Monitoring Application

- Monitor the spread material’s consistency, thickness, and texture

- Adjust the spreader’s settings as needed to optimize the application

3. What safety precautions do you observe while operating a mechanical spreader?

To ensure safety, I adhere to these precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection

- Inspect the work area for potential hazards and clear any obstacles

- Maintain a safe distance from other workers and equipment

4. How do you troubleshoot common problems encountered with mechanical spreaders?

When troubleshooting issues, I follow these steps:

- Identify the problem and isolate its cause

- Refer to the manufacturer’s instructions for specific troubleshooting guidance

- Check for loose connections, blockages, or worn components

- Make necessary adjustments or repairs to resolve the problem

5. What techniques do you use to minimize material waste and maximize efficiency?

To optimize material usage and efficiency, I employ these techniques:

- Plan the application route to avoid overlaps and minimize waste

- Use a spreader with adjustable settings to control material depth and width

- Monitor the application process closely and make adjustments as needed

6. How do you communicate effectively with other crew members to ensure a smooth operation?

Effective communication is crucial:

- Establish clear communication channels and protocols

- Use hand signals, radios, or walkie-talkies for efficient communication

- Provide regular updates on progress and any potential issues

7. How do you stay updated on the latest industry best practices and technological advancements in mechanical spreading?

To stay current, I:

- Attend industry workshops and training programs

- Read trade publications and technical manuals

- Consult with manufacturers and suppliers for updates on equipment and techniques

8. How do you prioritize multiple tasks and manage your time effectively?

Prioritizing tasks and managing time efficiently are crucial:

- Create a daily or weekly schedule and prioritize tasks based on importance and urgency

- Break down large tasks into smaller, manageable steps

- Delegate tasks to other crew members when feasible

9. How do you maintain a positive and productive work environment within the crew?

Maintaining a positive work environment is essential:

- Communicate openly and respectfully with crew members

- Provide positive feedback and recognition for good work

- Address conflicts promptly and professionally

10. What is your understanding of the different types of mechanical spreaders and their applications?

There are several types of mechanical spreaders, each with its own applications:

- Chip Spreaders: Apply small aggregate materials such as gravel or chips

- Asphalt Spreaders: Used for paving roads and parking lots

- Concrete Spreaders: Designed for spreading concrete evenly and precisely

- Soil Spreaders: Used in landscaping and agricultural applications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanical Spreader Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanical Spreader Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operate and maintain mechanical spreaders

Operate and maintain mechanical spreaders used to apply materials such as fertilizer, seed, and chemicals to agricultural fields. Ensure that spreaders are in good working order and calibrated to apply materials at the correct rate.

2. Plan spreading routes and determine application rates

Plan spreading routes to ensure even coverage of materials and minimize overlap. Determine application rates based on field size, crop type, and soil conditions.

3. Inspect fields and monitor crop growth

Inspect fields to assess crop growth and identify areas that require additional treatment. Monitor crop growth and adjust application rates as needed.

4. Keep records and report on spreading activities

Keep accurate records of spreading activities, including materials used, application rates, and field conditions. Report on spreading activities to management and customers.

Interview Tips

1. Research the company and the position

Before the interview, research the company, its values, and the specific position you are applying for. This will help you understand the company’s culture and the expectations of the role.

2. Practice answering common interview questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and prepared during the interview.

3. Highlight your relevant experience and skills

When answering questions, be sure to highlight your relevant experience and skills. Use specific examples to demonstrate your abilities.

4. Be enthusiastic and positive

Throughout the interview, maintain a positive and enthusiastic attitude. This will show the interviewer that you are genuinely interested in the position and the company.

5. Ask questions

At the end of the interview, ask questions to show your interest in the position and the company. This is also an opportunity to clarify any information or ask about the next steps in the hiring process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mechanical Spreader Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!