Are you gearing up for an interview for a Mechanical Striper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Mechanical Striper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

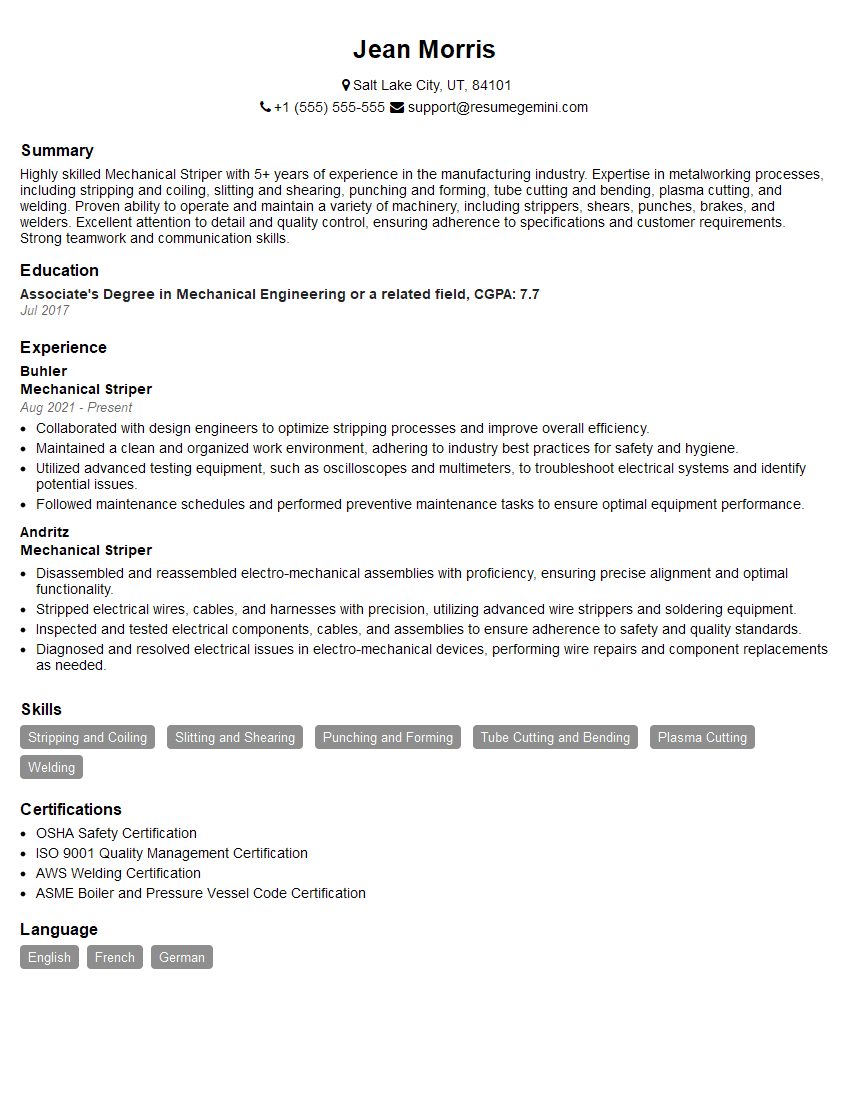

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanical Striper

1. Explain the process of stripping insulation from wire using a mechanical stripper?

- Place the wire into the stripper’s jaws, ensuring it is properly aligned.

- Adjust the stripper’s settings to the appropriate wire size and insulation type.

- Engage the stripper’s stripping mechanism to remove the insulation from the wire.

- Inspect the stripped wire to ensure the insulation has been removed cleanly and the conductor is not damaged.

2. What are the different types of mechanical strippers and their applications?

Manual strippers

- Handheld and require manual force to strip the wire.

- Suitable for small-scale operations or occasional use.

Semi-automatic strippers

- Use a foot pedal or trigger to activate the stripping mechanism.

- Faster than manual strippers, suitable for medium-scale operations.

Automatic strippers

- Fully automated, requiring no manual input.

- Used for large-scale production or high-volume stripping.

3. How do you determine the correct blade size for a mechanical stripper?

- Measure the diameter of the wire to be stripped.

- Refer to the stripper’s specifications or use a sizing chart to determine the appropriate blade size.

- Ensure the blade is sharp and in good condition.

4. What safety precautions should be taken when using a mechanical stripper?

- Wear appropriate safety gear, including gloves and safety glasses.

- Ensure the stripper is properly grounded to prevent electrical shock.

- Do not use the stripper on live wires.

- Keep the stripper clean and well-maintained.

5. How do you troubleshoot common problems with mechanical strippers?

- Stripper not cutting cleanly: Check the blade sharpness, blade size, or wire alignment.

- Stripper not gripping the wire properly: Adjust the stripper’s settings or clean the jaws.

- Stripper not stripping the insulation completely: Check the blade depth or tension settings.

- Stripper damaging the conductor: Inspect the blade for damage or alignment issues.

6. What is the difference between a mechanical stripper and a thermal stripper?

- Mechanical stripper: Uses blades to physically cut the insulation.

- Thermal stripper: Uses heat to melt the insulation.

7. What are the advantages and disadvantages of using a mechanical stripper?

Advantages

- Fast and efficient for high-volume stripping.

- Produces clean and consistent results.

- Durable and long-lasting with proper maintenance.

Disadvantages

- Can be expensive to purchase and maintain.

- May not be suitable for small-scale or occasional use.

- Requires careful setup and calibration for optimal performance.

8. What is the importance of proper blade maintenance for mechanical strippers?

- Sharp blades ensure clean cuts and prevent damage to the wire.

- Regular blade maintenance extends the stripper’s lifespan.

- Properly maintained blades reduce the risk of accidents or injuries.

9. How do you calibrate a mechanical stripper?

- Follow the manufacturer’s instructions for the specific stripper model.

- Use a calibration tool or test wires to adjust the blade depth and tension.

- Ensure the stripper is calibrated to the appropriate wire size and insulation type.

10. What are the key considerations when choosing a mechanical stripper?

- Wire size and insulation type: The stripper must be capable of handling the specific wire and insulation.

- Volume and frequency of use: Consider the production requirements to determine the appropriate stripper type.

- Features and capabilities: Evaluate additional features such as automatic feed, blade adjustment, and safety mechanisms.

- Budget and maintenance cost: Factor in the initial investment and ongoing maintenance expenses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanical Striper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanical Striper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Mechanical Stripper is employed by a manufacturing company specialising in the stripping of coatings and materials from a variety of substrates. The key responsibilities of a Mechanical Stripper include:

1. Equipment Maintenance and Operation

A Mechanical Stripper is responsible for ensuring that all equipment involved in the stripping process is in good working order. This includes performing regular maintenance and calibrations, as well as troubleshooting and repairing any issues that may arise.

- Performing routine maintenance checks on equipment

- Calibrating and adjusting equipment

- Troubleshooting and repairing equipment

2. Stripping Process

The primary responsibility of a Mechanical Stripper is to operate the stripping equipment to remove coatings and materials from substrates. This involves selecting the appropriate stripping method and settings, as well as monitoring the process to ensure that it is being carried out safely and effectively.

- Selecting the appropriate stripping method and settings

- Loading and unloading substrates

- Monitoring the stripping process

3. Quality Control

To ensure that the stripped substrates meet the required standards, Mechanical Strippers are responsible for conducting quality control checks throughout the stripping process. This involves inspecting substrates for defects, measuring the thickness of the removed coating, and ensuring that the surface finish meets specifications.

- Inspecting substrates for defects

- Measuring the thickness of the removed coating

- Ensuring that the surface finish meets specifications

4. Safety Compliance

As the stripping process involves the use of hazardous materials and equipment, Mechanical Strippers are responsible for ensuring that all safety regulations are followed. This includes wearing the appropriate personal protective equipment, following proper handling procedures, and maintaining a clean and organised work area.

- Wearing the appropriate personal protective equipment

- Following proper handling procedures

- Maintaining a clean and organised work area

Interview Tips

Preparing for an interview is essentially a three-step process: research, practice, and presentation.

1. Research

One of the most important things you can do before an interview is to research the company and the position you’re applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position. You can find this information on the company’s website, as well as in industry publications and news articles.

- Visit the company’s website

- Read industry publications and news articles

- Talk to people in your network who work at the company

2. Practice

Once you’ve done your research, it’s time to start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview, which will increase your chances of success.

- Practice answering common interview questions

- Record yourself answering questions and watch it back

- Ask a friend or family member to mock interview you

3. Presentation

On the day of the interview, it’s important to make a good first impression. This means dressing professionally, arriving on time, and being prepared to answer questions. It’s also important to be polite and respectful to everyone you meet, including the receptionist, the interviewer, and other employees.

- Dress professionally

- Arrive on time

- Be prepared to answer questions

- Be polite and respectful

Next Step:

Now that you’re armed with the knowledge of Mechanical Striper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Mechanical Striper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini