Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Mechanical Unit Repairer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Mechanical Unit Repairer so you can tailor your answers to impress potential employers.

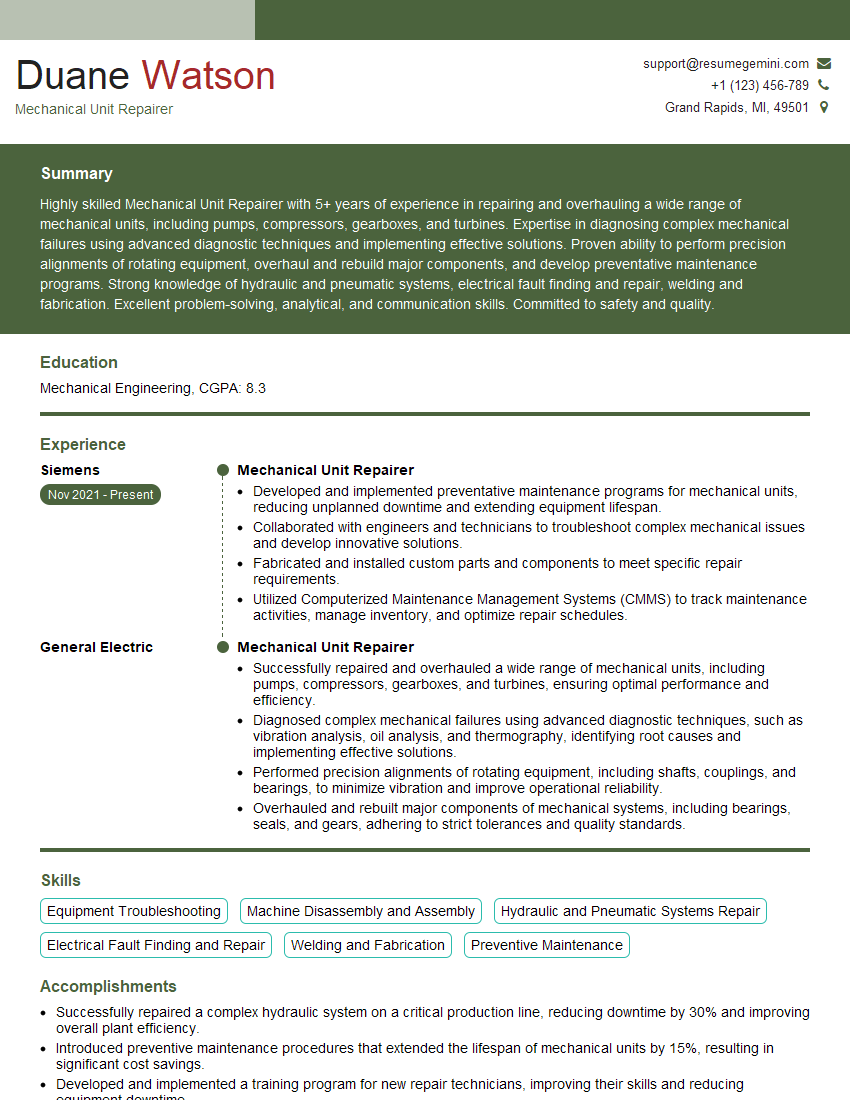

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mechanical Unit Repairer

1. How do you troubleshoot a hydraulic system that is leaking?

To troubleshoot a hydraulic system that is leaking, I would follow these steps:

- Inspect the system for any visible leaks.

- Check the hydraulic fluid level and condition.

- Test the system pressure.

- Inspect the hoses and fittings for any damage.

- Check the pump and motor for any leaks.

- Inspect the valves and cylinders for any leaks.

2. What are the different types of bearings used in mechanical units?

Types of bearings

- Rolling bearings

- Sliding bearings

Rolling bearings

- Ball bearings

- Roller bearings

- Tapered roller bearings

- Needle bearings

Sliding bearings

- Plain bearings

- Hydrodynamic bearings

- Hydrostatic bearings

- Gas bearings

3. How do you align a shaft and coupling?

To align a shaft and coupling, I would use a laser alignment tool. This tool allows me to precisely align the shafts and ensure that they are running smoothly.

- Mount the laser alignment tool on the shafts.

- Adjust the shafts until the laser beams are aligned.

- Tighten the coupling bolts.

- Check the alignment again to ensure that it is correct.

4. What are the different types of seals used in mechanical units?

- Lip seals

- O-rings

- V-rings

- T-rings

- U-rings

- Chevron seals

- Diaphragm seals

- Gaskets

5. How do you maintain a gearbox?

To maintain a gearbox, I would perform the following tasks:

- Inspect the gearbox for any leaks or damage.

- Check the oil level and condition.

- Change the oil and filter as per the manufacturer’s recommendations.

- Inspect the gears and bearings for any wear or damage.

- Lubricate the gearbox as per the manufacturer’s recommendations.

6. What are the different types of lubricants used in mechanical units?

- Oils

- Greases

- Solid lubricants

Oils

- Mineral oils

- Synthetic oils

Greases

- Lithium greases

- Calcium greases

- Sodium greases

- Synthetic greases

Solid lubricants

- Graphite

- Molybdenum disulfide

- Polytetrafluoroethylene (PTFE)

7. How do you troubleshoot a mechanical unit that is not functioning properly?

To troubleshoot a mechanical unit that is not functioning properly, I would follow these steps:

- Inspect the unit for any visible damage.

- Check the power supply to the unit.

- Check the controls for the unit.

- Inspect the unit for any loose or damaged parts.

- Test the unit using a diagnostic tool.

- Repair or replace any faulty parts.

8. What safety precautions should be taken when working on mechanical units?

When working on mechanical units, it is important to take the following safety precautions:

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Lock out and tag out the unit before performing any maintenance or repairs.

- Be aware of potential hazards, such as moving parts, sharp edges, and hot surfaces.

- Use proper tools and equipment for the job.

- Follow all manufacturer’s instructions and safety guidelines.

9. What is your experience with using diagnostic tools?

I have experience using a variety of diagnostic tools, including:

- Multimeters

- Oscilloscopes

- Logic analyzers

- Vibration analyzers

- Thermal imaging cameras

I am proficient in using these tools to troubleshoot and repair mechanical units.

10. What is your experience with repairing mechanical units?

I have experience repairing a variety of mechanical units, including:

- Engines

- Gearboxes

- Pumps

- Compressors

- Hydraulic systems

I am proficient in diagnosing and repairing these units, and I have a proven track record of success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mechanical Unit Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mechanical Unit Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mechanical Unit Repairers handle the maintenance and repair of complex mechanical units and systems. A thorough understanding of mechanical principles, maintenance procedures, and safety protocols are essential for the role. The core responsibilities of a Mechanical Unit Repairer typically include:

1. Maintenance and Repair

Conducting routine maintenance inspections, diagnosing faults, and carrying out repairs for various mechanical units and systems to ensure optimal performance and prevent breakdowns.

2. Troubleshooting

Identifying and resolving mechanical issues by analyzing symptoms, conducting tests, and determining appropriate repair solutions.

3. Equipment Modification and Installation

Modifying and installing new or upgraded mechanical components and systems to enhance functionality and meet changing operational requirements.

4. Preventative Maintenance

Developing and implementing preventive maintenance plans, including lubrication, adjustments, and cleaning, to minimize the risk of breakdowns and extend the life of equipment.

5. Safety and Compliance

Maintaining a safe work environment by adhering to safety regulations, using appropriate equipment, and ensuring that repaired units meet safety standards.

Interview Tips

Preparing for an interview as a Mechanical Unit Repairer requires a balanced approach. By combining thorough research, self-reflection, and practice, you can increase your chances of making a strong impression:

1. Research the Company and Role

Understanding the company’s culture, industry, and specific requirements for the Mechanical Unit Repairer position will help you align your answers with their expectations.

2. Highlight Relevant Experience and Skills

Focus on showcasing your technical expertise in mechanical repair, troubleshooting, and preventative maintenance. Quantify your accomplishments using specific examples to demonstrate your impact.

3. Emphasize Safety and Compliance

Mechanical Unit Repairers have a fundamental responsibility for safety. Highlight your commitment to safety protocols, adherence to regulations, and the ability to identify and mitigate potential hazards.

4. Prepare for Technical Questions

Be prepared to answer questions related to your understanding of mechanical principles, troubleshooting techniques, and maintenance procedures. Practice explaining complex concepts in a clear and concise manner.

5. Practice STAR Method

Use the STAR method (Situation, Task, Action, Result) to structure your answers to behavioral questions. This method helps you effectively communicate your experiences, skills, and accomplishments.

6. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your interest and engagement. Prepare questions about the company’s growth plans, the team you’ll be working with, and any opportunities for professional development.

7. Professionalism and Confidence

Dress professionally, arrive on time, and maintain a positive and respectful demeanor throughout the interview. Confidence in your abilities and a genuine interest in the role will make a lasting impression.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Mechanical Unit Repairer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.