Are you gearing up for an interview for a Medical Device Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Medical Device Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

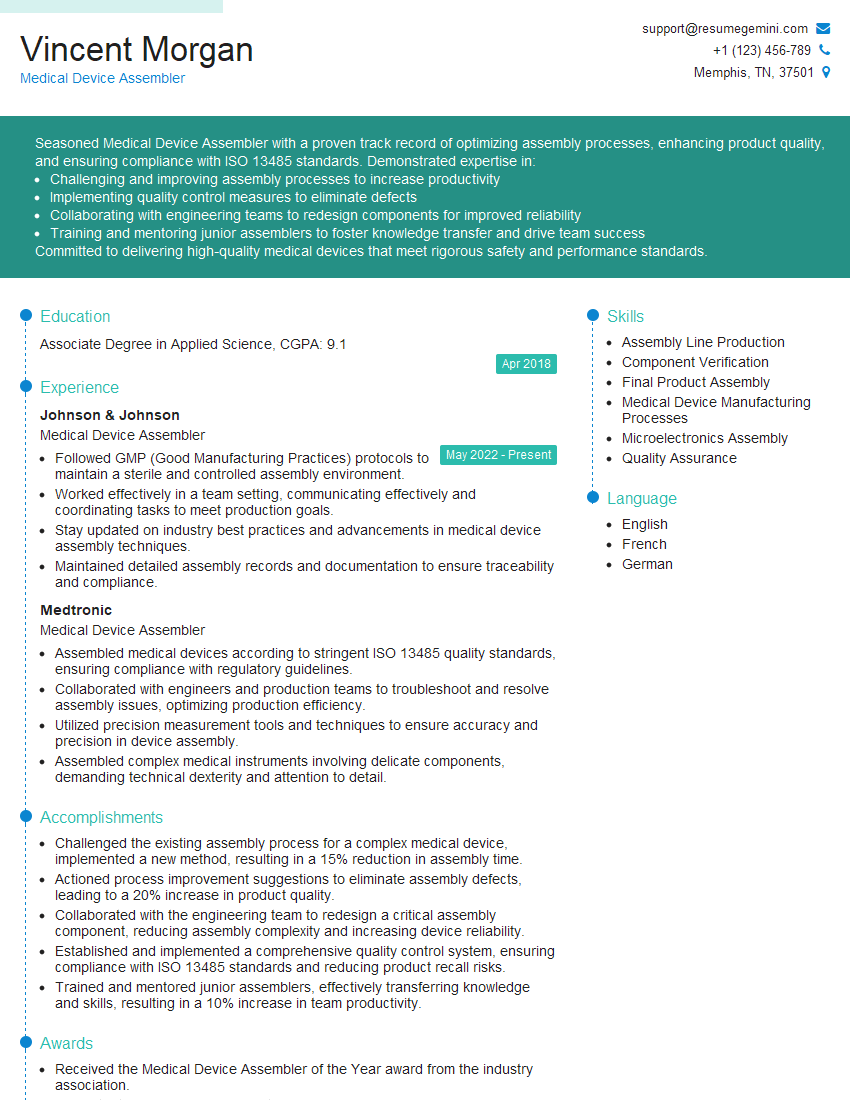

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Medical Device Assembler

1. Describe the process of assembling a medical device, step by step?

Sample Answer

- Read and understand the assembly instructions.

- Gather the necessary components and tools.

- Prepare the workspace by cleaning and organizing.

- Assemble the components according to the instructions, using precision tools and techniques.

- Inspect the assembled device for defects and ensure it meets specifications.

- Package and sterilize the device as per requirements.

2. What are the different types of medical devices you have experience assembling?

Sample Answer

- Stents

- Catheters

- Surgical instruments

- Implantable devices

- Diagnostics devices

3. How do you ensure the quality of the medical devices you assemble?

Sample Answer

- Follow strict assembly protocols and guidelines.

- Use precision tools and techniques for accurate assembly.

- Inspect components and devices at each stage of assembly.

- Adhere to quality control standards and regulations.

- Document assembly processes and results for traceability.

4. What are some of the challenges you have encountered in medical device assembly and how did you overcome them?

Sample Answer

- Working with delicate and complex components.

- Used precision tools and handled components with care.

- Meeting tight deadlines without compromising quality.

- Optimized assembly processes, prioritized tasks, and communicated with team members.

- Ensuring sterility and cleanliness during assembly.

- Followed strict protocols, used sterile tools, and maintained a clean workspace.

Challenge:

Solution:

Challenge:

Solution:

Challenge:

Solution:

5. What is your understanding of the importance of calibration and maintenance of assembly equipment?

Sample Answer

- Ensure accurate and precise assembly.

- Prevent errors and defects in medical devices.

- Maximize equipment lifespan and efficiency.

- Comply with industry regulations and standards.

- Minimize downtime and reduce maintenance costs.

6. How do you stay up-to-date on the latest advancements in medical device assembly techniques?

Sample Answer

- Attend industry workshops and conferences.

- Read technical publications and journals.

- Network with other medical device assemblers.

- Receive training from equipment manufacturers.

- Implement continuous improvement initiatives.

7. Describe your experience with cleanroom assembly environments.

Sample Answer

- Understanding and adhering to cleanroom protocols.

- Wearing appropriate personal protective equipment (PPE).

- Maintaining a clean and sterile workspace.

- Handling components and devices with care to avoid contamination.

- Following quality control procedures to ensure product integrity.

8. What are the safety precautions you take when assembling medical devices?

Sample Answer

- Wear appropriate PPE, including gloves, safety glasses, and lab coats.

- Handle sharp or hazardous materials with care.

- Follow proper handling and disposal procedures for chemicals and waste.

- Maintain a clean and organized work area.

- Be aware of potential hazards and take steps to mitigate risks.

9. How do you prioritize and manage multiple assembly tasks effectively?

Sample Answer

- Review assembly instructions and identify critical tasks.

- Set priorities based on deadlines and device importance.

- Create a work schedule and allocate time for each task.

- Communicate with team members and delegate responsibilities.

- Monitor progress and make adjustments as needed.

10. How do you handle and resolve assembly errors or defects?

Sample Answer

- Identify and document the error or defect.

- Determine the root cause of the issue.

- Implement corrective actions to resolve the error.

- Retest or inspect the device to ensure it meets specifications.

- Report errors and defects to supervisors and follow quality control procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Medical Device Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Medical Device Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Medical Device Assemblers play a crucial role in the healthcare industry, ensuring the precise assembly of medical devices that are vital for patient care. Their responsibilities encompass a wide range of tasks necessary for the production of high-quality medical devices.

1. Assembly Process

Assemblers are responsible for following assembly instructions and adhering to strict quality standards.

- Interpreting and following assembly drawings, schematics, and work orders.

- Selecting and installing appropriate components, ensuring proper fit and functionality.

- Operating assembly equipment and tools to join components using techniques such as soldering, welding, and bonding.

2. Quality Control

Ensuring the quality of assembled devices is paramount to patient safety and regulatory compliance.

- Inspecting assembled devices for defects or deviations from specifications.

- Conducting functional testing to verify device performance and compliance with design requirements.

- Maintaining accurate records of assembly and inspection processes for traceability and quality assurance.

3. Sterilization and Packaging

Medical devices must be sterilized before use to prevent the transmission of infections.

- Preparing devices for sterilization using appropriate methods such as autoclaving or ethylene oxide gas.

- Packaging and labeling devices according to specifications and regulatory requirements.

4. Safety and Compliance

Assemblers must adhere to safety protocols and regulatory guidelines to ensure a safe and compliant work environment.

- Following established safety procedures for handling and using equipment and materials.

- Maintaining a clean and organized work area to minimize contamination and hazards.

- Understanding and complying with relevant industry regulations and standards, such as ISO 13485.

Interview Tips

Preparing for an interview for a Medical Device Assembler position requires careful consideration and a strategic approach. Here are some tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s mission, values, and the specific responsibilities of the Medical Device Assembler role. This will allow you to tailor your answers and demonstrate your understanding of the industry.

2. Highlight Relevant Experience

Emphasize your previous experience in assembly, quality control, or related fields. Provide specific examples that showcase your skills and abilities, quantifying your results whenever possible.

3. Practice Common Interview Questions

Anticipate and prepare for common interview questions, such as: “Why are you interested in this role?”, “What is your experience with medical device assembly?”, and “How would you handle a quality issue?”.

4. Showcase Your Attention to Detail

Medical Device Assemblers must possess a keen eye for detail. Highlight your ability to follow instructions precisely, identify defects, and ensure accuracy in your work.

5. Emphasize Safety and Compliance

Understanding and adhering to safety protocols and regulatory guidelines is essential in this field. Explain your commitment to maintaining a safe and compliant work environment.

6. Be Prepared to Discuss Quality Control Processes

Describe your knowledge of quality control techniques, such as inspection, testing, and documentation. Explain how you ensure the quality and integrity of assembled devices.

7. Show Enthusiasm and Motivation

Convey your passion for working in the healthcare industry and your desire to contribute to patient care. Highlight your willingness to learn and grow within the role.

Next Step:

Now that you’re armed with the knowledge of Medical Device Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Medical Device Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini