Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Medical or Surgical Instrument Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

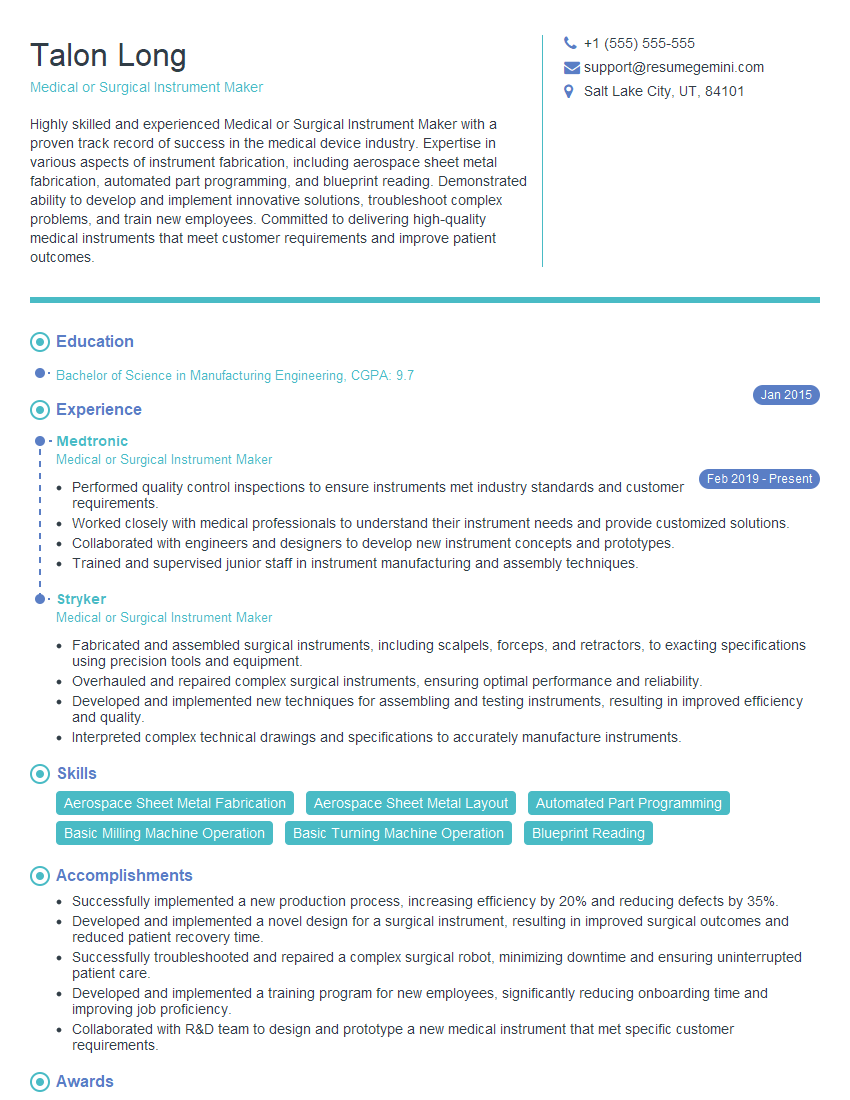

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Medical or Surgical Instrument Maker

1. Describe the process of manufacturing a surgical instrument, from design to final assembly.

In the manufacturing of a surgical instrument, the process typically involves the following steps:

- Design and development: The process begins with the conceptualization and design of the instrument, taking into account factors such as its intended purpose, ergonomics, and materials.

- Prototyping: Once the design is finalized, a prototype is created to evaluate its functionality and make necessary adjustments.

- Material selection: The choice of materials for the instrument is crucial, considering factors such as biocompatibility, durability, and sterilization requirements.

- Fabrication: The instrument’s components are manufactured using various techniques, such as machining, forging, or casting, to achieve the desired shape and dimensions.

- Assembly: The fabricated components are assembled together to form the complete instrument, ensuring proper fit and function.

- Finishing and sterilization: The instrument undergoes finishing processes such as polishing or coating to enhance its surface properties. It is then sterilized to eliminate any microorganisms before packaging and distribution.

2. What are the different types of materials used in the production of medical and surgical instruments?

Metals:

- Stainless steel: Durable, corrosion-resistant, and widely used in surgical instruments.

- Titanium: Lightweight, strong, and biocompatible, suitable for implants and surgical tools.

- Cobalt-chromium alloys: Hard, wear-resistant, and used in joint replacements and dental instruments.

Polymers:

- Polycarbonate: Transparent, impact-resistant, and used in surgical trays and containers.

- Polyetheretherketone (PEEK): High-strength, biocompatible, and used in spinal implants and surgical devices.

- Silicone: Flexible, biocompatible, and used in catheters, tubing, and surgical seals.

Ceramics:

- Zirconia: Hard, wear-resistant, and used in dental implants and cutting tools.

- Hydroxyapatite: Biocompatible, osteoconductive, and used in bone implants.

3. Explain the importance of quality control in the manufacturing of medical devices.

Quality control in the manufacturing of medical devices is paramount for the following reasons:

- Patient safety: Medical devices directly impact patient health, and ensuring their quality is crucial to prevent harm or complications.

- Regulatory compliance: Manufacturers must adhere to stringent regulations set by regulatory bodies to ensure the safety and efficacy of medical devices.

- Brand reputation: High-quality medical devices enhance the reputation of the manufacturer and build trust among healthcare providers and patients.

- Cost-effectiveness: Preventing defects and ensuring quality can reduce the cost of recalls, legal liabilities, and customer dissatisfaction.

4. Describe the different methods used to test the performance of medical devices.

Various methods are employed to test the performance of medical devices, including:

- Bench testing: Laboratory testing of devices under controlled conditions to evaluate their electrical, mechanical, and functional characteristics.

- Animal testing: In vivo testing in animals to assess biocompatibility, safety, and efficacy of devices.

- Clinical trials: Human studies to evaluate the safety and effectiveness of devices in real-world settings.

- Accelerated life testing: Testing devices under extreme conditions to simulate long-term use and identify potential failure points.

5. What are the challenges faced in the design and manufacture of minimally invasive surgical instruments?

Minimally invasive surgical instruments pose unique challenges:

- Small size and dexterity: Instruments must be miniaturized to access small anatomical spaces, requiring precise design and manufacturing.

- Multiple functionalities: Minimally invasive instruments often incorporate multiple functions, adding complexity to design.

- Sterilizability: Instruments must withstand repeated sterilization without compromising their performance or materials.

- Cost: Miniaturization and complex designs can increase manufacturing costs, which must be balanced with affordability.

6. Explain the role of computer-aided design (CAD) and computer-aided manufacturing (CAM) in the production of medical devices.

CAD and CAM play vital roles in medical device production:

- CAD: Used to design and create 3D models of medical devices, allowing for precise design iteration and optimization.

- CAM: Converts CAD designs into instructions for CNC machines, enabling automated manufacturing of devices with high accuracy and repeatability.

7. Describe the process of reverse engineering a medical device.

Reverse engineering involves:

- Disassembly: Taking apart the device to study its components and design.

- Measurement and documentation: Recording dimensions, materials, and functionality of each component.

- 3D scanning: Capturing the shape and dimensions of the device using a 3D scanner.

- CAD modeling: Creating a 3D CAD model based on the collected data.

8. What are the ethical considerations in the design and manufacture of medical devices?

Ethical considerations include:

- Patient safety: Ensuring the safety and efficacy of devices above all else.

- Informed consent: Obtaining patient consent before using experimental or invasive devices.

- Privacy: Protecting patient data collected by medical devices.

- Conflict of interest: Avoiding conflicts between financial interests and patient well-being.

9. Discuss the future trends in the medical device industry.

Trends include:

- Personalized medicine: Devices tailored to individual patient needs.

- Wearable devices: Monitoring and tracking health parameters remotely.

- AI and machine learning: Enhancing device performance, disease diagnosis, and patient outcomes.

- Nanotechnology: Developing miniaturized devices for targeted therapies.

10. Describe a challenging project you have worked on and how you overcame the obstacles.

Provide a specific example of a challenging project, highlighting:

- Problem statement: Clearly define the problem encountered.

- Analytical approach: Explain the steps taken to identify the root cause.

- Technical solutions: Describe the technical solutions implemented.

- Results achieved: Quantify the improvements or benefits of your solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Medical or Surgical Instrument Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Medical or Surgical Instrument Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Medical or surgical instrument makers are responsible for producing instruments used in medical and surgical procedures. Their tasks may vary depending on the specific industry and company they work for, but some common key job responsibilities include:- Work with engineers and product designers to develop new products.

- Design and build prototypes of medical and surgical instruments.

- Maintain and repair medical and surgical instruments.

- Inspect and test medical and surgical instruments to ensure they meet quality standards.

- Write instructions for the use and maintenance of medical and surgical instruments.

- Stay up-to-date on the latest advances in medical technology.

- Follow all safety regulations and procedures.

Interview Tips

If you’re looking to land a job as a medical or surgical instrument maker, there are a few things you can do to prepare for your interview.1. Research the company and the position:

Make sure you have a good understanding of the company’s culture, values, and products. You should also be familiar with the specific job requirements and responsibilities.2. Practice your answers to common interview questions:

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to prepare your answers to these questions in advance.3: Show your passion and enthusiasm.

Medical or surgical instrument makers are often passionate about their work. They’re also typically enthusiastic about the medical field and the role that their products play in helping patients. Showing your passion and enthusiasm for the job during your interview can help you make a positive impression on the hiring manager.4. Prepare to discuss your skills and experience:

The interviewer will likely want to know about your skills and experience as a medical or surgical instrument maker. Be prepared to discuss your technical skills, as well as your experience with specific types of medical or surgical instruments.5. Be prepared to talk about your safety knowledge:

Medical or surgical instrument makers must be familiar with all safety regulations and procedures. Be prepared to discuss your safety knowledge and experience in your interview. By following these tips, you can increase your chances of acing your interview and landing the job you want.Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Medical or Surgical Instrument Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.