Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Melter – Caster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

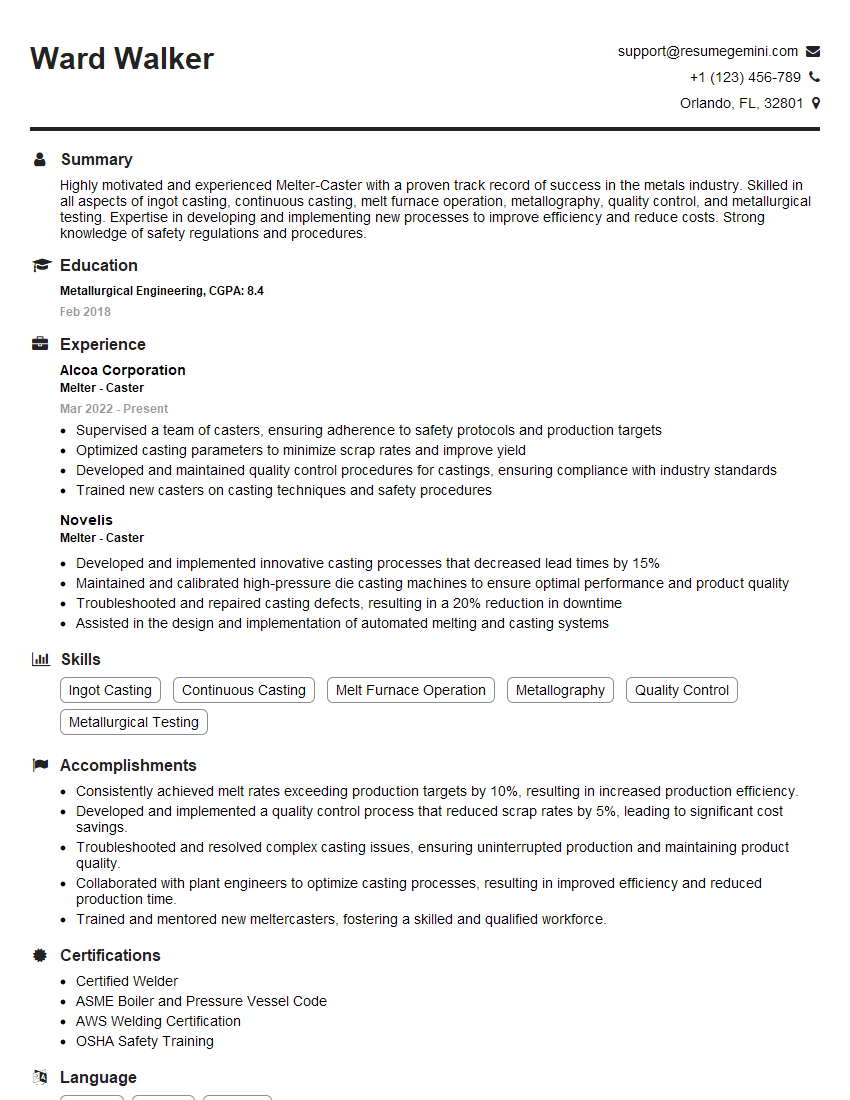

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Melter – Caster

1. What are the main responsibilities of a Melter – Caster?

The primary responsibilities of a Melter – Caster include:

- Operating and maintaining melting and casting equipment, including furnaces, ladles, and casting machines.

- Monitoring and controlling the melting and casting process, ensuring adherence to quality standards.

- Inspecting finished castings for defects and non-conformances.

- Performing maintenance and repairs on melting and casting equipment.

- Adhering to safety protocols and regulations.

2. What are the different types of melting and casting processes?

Electric arc furnace (EAF)

- Uses electric arcs to melt scrap metal and create molten steel.

- Produces high-quality steel with low impurities.

Basic oxygen furnace (BOF)

- Uses oxygen to refine molten iron, producing steel.

- Produces large quantities of steel efficiently.

Continuous casting

- Molten metal is continuously cast into slabs, billets, or blooms.

- Reduces production time and improves efficiency.

Sand casting

- Molten metal is poured into sand molds to create castings.

- Suitable for complex shapes and small production runs.

3. What are the key factors that affect the quality of castings?

The quality of castings is influenced by several factors, including:

- Composition of the molten metal

- Melting and casting temperatures

- Mold design and preparation

- Casting speed and cooling rate

- Post-casting heat treatment

4. How do you troubleshoot common casting defects?

Common casting defects include:

- Shrinkage cavities

- Gas porosity

- Cracks

- Inclusions

Troubleshooting involves identifying the root cause of the defect, such as:

- Improper melting or casting parameters

- Mold design or preparation issues

- Contamination of the molten metal

5. What safety precautions are essential in a melting and casting facility?

Safety precautions include:

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

- Following proper operating procedures

- Handling molten metal with care

- Being aware of potential hazards, such as heat, sparks, and fumes

6. How do you monitor and control the melting and casting process?

Monitoring involves:

- Observing furnace temperatures and molten metal flow

- Taking samples for chemical analysis

- Inspecting castings for defects

Control involves adjusting process parameters such as:

- Furnace temperature

- Casting speed

- Mold temperature

7. What experience do you have in operating and maintaining melting and casting equipment?

Provide specific examples of your involvement in operating and maintaining melting and casting equipment, including:

- Type of equipment operated and maintained

- Tasks performed, such as equipment inspections, repairs, and troubleshooting

- Measures taken to ensure equipment reliability and safety

8. How do you ensure the quality of castings produced?

Quality assurance involves:

- Adhering to established quality standards

- Performing regular inspections and testing

- Maintaining process records and documentation

- Implementing continuous improvement initiatives

- Collaborating with other departments, such as quality control and engineering

9. How do you stay updated on the latest developments in the melting and casting industry?

Staying updated can be achieved through:

- Attending industry conferences and seminars

- Reading technical journals and publications

- Participating in professional organizations

- Seeking training and certification opportunities

10. Why should we hire you as a Melter – Caster?

Highlight your skills, experience, and qualifications that make you an ideal candidate, such as:

- Proficiency in melting and casting operations

- Strong understanding of metallurgy and casting processes

- Experience in quality assurance and safety procedures

- Excellent communication and teamwork skills

Express your enthusiasm for the role and the industry, and how you can contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Melter – Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Melter – Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Melters – Casters utilize specialized equipment and knowledge to transform raw materials into molten metal and cast it into molds, ensuring the production of high-quality metal components.

1. Raw Material Handling and Preparation

Inspecting incoming raw materials (e.g., scrap metal, alloys) to verify quality and compliance.

- Preparing raw materials by sorting, cleaning, and blending them to meet specific specifications.

- Operating equipment to melt down and refine raw materials, removing impurities and controlling the chemical composition.

2. Casting Operations

Setting up and operating casting equipment, including molds, dies, and furnaces.

- Pouring molten metal into molds and controlling the casting process to ensure the production of quality castings.

- Inspecting castings for defects, dimensions, and adherence to specifications.

3. Quality Control and Inspection

Performing visual and dimensional inspections of castings to identify any defects.

- Analyzing chemical composition and physical properties of castings to ensure they meet customer requirements.

- Identifying and resolving casting issues, implementing corrective actions to improve quality.

4. Equipment Maintenance and Troubleshooting

Performing routine maintenance and repairs on casting equipment to ensure optimal performance.

- Monitoring equipment for signs of wear or damage, taking proactive measures to prevent breakdowns.

- Troubleshooting and resolving equipment issues, minimizing downtime and maintaining productivity.

Interview Tips

Preparation is key when it comes to acing an interview for a Melter – Caster position. Apart from thoroughly understanding the job responsibilities mentioned above, here are some tips to enhance your chances of success:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, services, and industry trends. This will help you engage in meaningful conversations and demonstrate your interest in the specific role.

- Review the company’s website, LinkedIn page, and industry news to gather relevant information.

2. Highlight Relevant Experience and Skills

Emphasize your experience in raw material handling, casting operations, quality control, and equipment maintenance. Quantify your achievements using specific metrics and examples.

- Discuss instances where you identified and resolved casting issues, resulting in improved product quality.

3. Be Prepared to Discuss Safety Procedures

Safety is paramount in the metalworking industry. Highlight your knowledge of relevant safety protocols and your commitment to maintaining a safe and compliant work environment.

- Share examples of how you have implemented safety measures to minimize risks and ensure the well-being of yourself and colleagues.

4. Demonstrate Proactive Problem-Solving

Melters – Casters often face unexpected challenges. Showcase your ability to analyze problems, identify root causes, and develop effective solutions.

- Describe a situation where you identified equipment issues early and took immediate action to prevent production delays.

5. Ask Thoughtful Questions

Prepared questions indicate your curiosity, engagement, and interest in the position. Ask questions about the company’s casting processes, quality standards, and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Melter – Caster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!