Are you gearing up for a career in Melter Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Melter Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

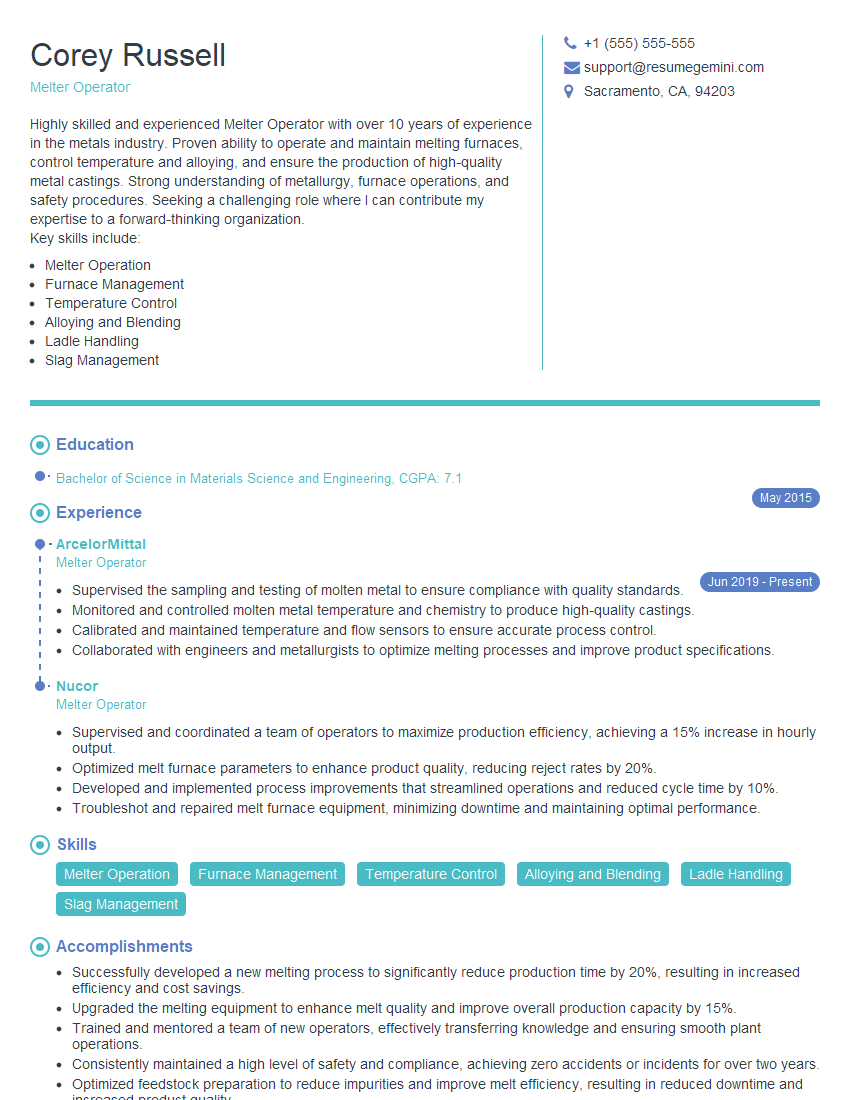

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Melter Operator

1. Describe your understanding of the melting process and its key stages?

- Melting involves converting raw materials into a molten state by applying heat and chemical reactions.

- Key stages include charging the furnace, heating and melting the materials, refining and homogenizing the melt, and tapping the molten metal.

2. Explain the role of different fluxes in the melting process.

Acidic fluxes

- Remove metallic oxides and impurities by forming a slag.

Basic fluxes

- Neutralize acidic impurities and lower the melting point of slag.

Neutral fluxes

- Protect the molten metal from oxidation and control slag formation.

3. Discuss the methods used to control and measure melt temperature.

- Thermocouples or pyrometers measure the temperature of the melt.

- Temperature is controlled by adjusting fuel flow, air flow, and oxygen enrichment.

4. Describe the safety precautions and procedures you follow when operating a melter.

- Wear appropriate protective gear, including gloves, goggles, and a fire-resistant suit.

- Ensure proper ventilation and exhaust systems to remove fumes and gases.

- Follow established procedures for handling molten metal and hazardous materials.

5. Explain the importance of slag control in the melting process.

- Slag absorbs impurities and prevents them from entering the molten metal.

- Slag controls the temperature and flowability of the melt.

- Slag disposal is essential for environmental compliance and waste management.

6. Discuss the different types of melters and their applications.

- Induction melters use electromagnetic induction to create heat.

- Arc furnaces use electric arcs to generate heat.

- Gas-fired melters use combustion of gas to provide heat.

7. Explain the maintenance and calibration procedures for a melter.

- Regularly inspect and clean the melter to prevent damage and ensure optimal performance.

- Calibrate sensors and gauges to ensure accurate readings of temperature, pressure, and flow.

- Perform scheduled maintenance tasks to extend the life of the melter.

8. Describe the quality control procedures you follow to ensure the quality of the molten metal.

- Conduct chemical analysis of the melt using spectrometers or other analytical techniques.

- Inspect the molten metal for defects, such as inclusions or porosity.

- Implement corrective actions based on quality control results.

9. Explain the environmental considerations and best practices for melter operation.

- Reduce emissions by using efficient combustion systems and controlling flue gas.

- Recycle and reuse materials, such as slag, to minimize waste.

- Adhere to environmental regulations and guidelines.

10. Describe your experience in troubleshooting and resolving common melter issues.

- Troubleshoot issues related to temperature control, slag formation, and molten metal quality.

- Analyze data and identify potential causes of problems.

- Implement solutions to resolve issues and ensure smooth melter operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Melter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Melter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Melter Operators play a crucial role in the production process, ensuring the efficient operation of melting furnaces and related equipment. Their primary responsibilities include:

1. Furnace Operation

Loading and unloading raw materials into and from the furnace

- Monitoring and adjusting furnace temperature and pressure

- Maintaining optimal furnace conditions to ensure product quality

2. Equipment Maintenance

Performing routine maintenance and inspections on furnaces and related equipment

- Identifying and troubleshooting equipment malfunctions

- Coordinating repairs and ensuring equipment is operational

3. Process Control

Monitoring and controlling the melting process to meet production targets

- Adjusting process parameters such as temperature, speed, and chemical composition

- Ensuring quality control and adherence to specifications

4. Material Handling

Receiving and handling raw materials, including ores, fluxes, and other additives

- Storing materials safely and efficiently

- Disposing of waste materials according to environmental regulations

Interview Tips

Preparing for a Melter Operator interview requires careful preparation and a deep understanding of the job responsibilities. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Learn about the company’s history, products, and industry trends. This will demonstrate your interest in the position and the company

- Visit the company website and industry publications

- Network with professionals in the field

2. Practice Your Technical Skills

Review your knowledge of melting furnaces, process control, and equipment maintenance. Practice answering technical questions confidently

- Solve sample problems related to furnace operation

- Describe how you would troubleshoot common equipment malfunctions

3. Highlight Your Safety Awareness

Melter Operators work in a potentially hazardous environment. Emphasize your understanding of safety protocols and your commitment to safe work practices

- Describe your experience with safety equipment and procedures

- Explain how you would respond to a safety hazard

4. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your problem-solving skills and teamwork abilities. Prepare examples that demonstrate your

- Ability to work effectively in a team environment

- Experience resolving conflicts and managing stress

- Commitment to continuous learning and improvement

5. Dress Professionally and Be on Time

First impressions matter. Dress professionally and arrive on time for your interview. This shows respect for the interviewer and the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Melter Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.