Are you gearing up for a career in Metal Alloy Scientist? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Alloy Scientist and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

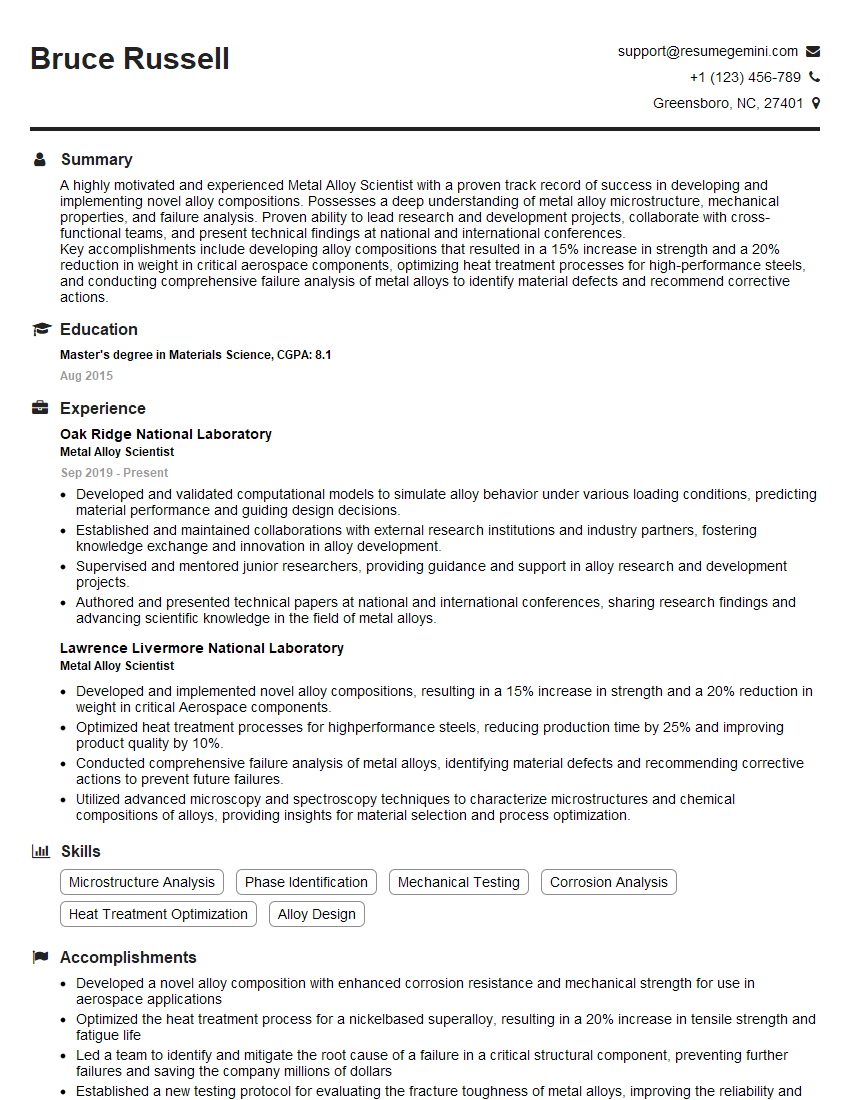

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Alloy Scientist

1. Explain the different types of metal alloys and their properties?

- Ferrous alloys: These alloys contain iron as their primary component. They are strong, durable, and magnetic. Common ferrous alloys include steel, cast iron, and wrought iron.

- Non-ferrous alloys: These alloys do not contain iron as their primary component. They are typically lighter, less strong, and less magnetic than ferrous alloys. Common non-ferrous alloys include aluminum, copper, and titanium.

2. Describe the different methods of alloying?

Mechanical alloying

- This method involves mechanically blending together different metal powders. The powders are then subjected to high pressure and temperature, which causes them to bond together.

Solid-state alloying

- This method involves heating two or more metals together in the solid state. The metals then diffuse into each other, forming an alloy.

Liquid-state alloying

- This method involves melting two or more metals together. The molten metals then mix together, forming an alloy.

3. What are the different factors that affect the properties of metal alloys?

- Composition: The composition of an alloy is the most important factor that affects its properties. The type and amount of each element in an alloy will determine its strength, hardness, ductility, and other properties.

- Processing: The way an alloy is processed can also affect its properties. For example, heat treatment can be used to improve the strength and hardness of an alloy.

- Environment: The environment in which an alloy is used can also affect its properties. For example, exposure to corrosive environments can cause an alloy to weaken or fail.

4. What are the different applications of metal alloys?

- Aerospace: Metal alloys are used in a variety of aerospace applications, such as aircraft, spacecraft, and missiles.

- Automotive: Metal alloys are used in a variety of automotive applications, such as engines, transmissions, and bodies.

- Medical: Metal alloys are used in a variety of medical applications, such as implants, surgical instruments, and prosthetics.

5. Describe the process of heat treating metal alloys?

- The process of heat treating metal alloys involves heating the alloy to a specific temperature and then cooling it at a controlled rate. This process can be used to improve the strength, hardness, ductility, and other properties of an alloy.

6. What is the difference between annealing, normalizing, and tempering?

-

Annealing: Annealing is a process that involves heating an alloy to a high temperature and then cooling it slowly. This process softens the alloy and makes it more ductile.

Normalizing: Normalizing is a process that involves heating an alloy to a high temperature and then cooling it in air. This process produces a microstructure that is more uniform than that produced by annealing.

Tempering: Tempering is a process that involves heating an alloy to a temperature below the critical temperature and then cooling it. This process improves the strength and hardness of the alloy.

7. What are the different types of corrosion?

-

Uniform corrosion: This is the most common type of corrosion. It occurs when the entire surface of a metal is attacked by a corrosive environment.

Localized corrosion: This type of corrosion occurs when a specific area of a metal is attacked by a corrosive environment.

Stress corrosion cracking: This type of corrosion occurs when a metal is subjected to both stress and a corrosive environment.

8. What are the different methods of preventing corrosion?

- Protective coatings: Protective coatings, such as paint, galvanizing, and anodizing, can be used to prevent corrosion.

- Cathodic protection: Cathodic protection is a method of preventing corrosion by connecting the metal to a more active metal, such as zinc.

- Inhibitors: Inhibitors are chemicals that can be added to a corrosive environment to slow down the rate of corrosion.

9. What are the different types of metalworking processes?

- Casting: Casting is a process that involves pouring molten metal into a mold. The metal then solidifies and takes the shape of the mold.

- Forging: Forging is a process that involves shaping metal by hammering or pressing it. This process can be used to create a variety of shapes, such as bars, rods, and sheets.

- Rolling: Rolling is a process that involves passing metal through a series of rollers. This process can be used to reduce the thickness of the metal or to create a specific shape.

10. What are the different types of welding processes?

- Arc welding: Arc welding is a process that involves using an electric arc to melt the metal together.

- Gas welding: Gas welding is a process that involves using a gas flame to melt the metal together.

- Resistance welding: Resistance welding is a process that involves using pressure and heat to weld the metal together.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Alloy Scientist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Alloy Scientist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Alloy Scientist is a professional who conducts research and development to create or improve metal alloys. Metal alloys are combinations of two or more metals that are mixed together to create a new material with specific properties. Metal Alloy Scientists work in a variety of industries, including aerospace, automotive, and manufacturing. They may also work in research and development laboratories.

1. Research and Develop New Alloys

Metal Alloy Scientists research and develop new alloys to meet the specific needs of their clients or employers. They may work with a variety of metals, including steel, aluminum, and titanium. They use their knowledge of metallurgy and chemistry to create alloys with the desired properties, such as strength, durability, and corrosion resistance.

- Conduct experiments to test the properties of new alloys

- Analyze data to determine the best combination of metals for a specific application

2. Improve Existing Alloys

Metal Alloy Scientists also work to improve existing alloys. They may do this by adding new elements to the alloy or by changing the heat treatment process. They use their knowledge of metallurgy to understand how different factors affect the properties of an alloy. They can then make changes to the alloy to improve its performance.

- Identify the problems with existing alloys

- Develop solutions to improve the performance of existing alloys

3. Test and Evaluate Alloys

Metal Alloy Scientists test and evaluate alloys to ensure that they meet the required specifications. They use a variety of testing methods, including tensile testing, hardness testing, and corrosion testing. They analyze the results of the tests to determine whether the alloy meets the desired properties.

- Conduct tensile tests to measure the strength of an alloy

- Conduct hardness tests to measure the hardness of an alloy

- Conduct corrosion tests to measure the corrosion resistance of an alloy

4. Write Technical Reports

Metal Alloy Scientists write technical reports to document their research and development work. They may also write reports on the properties of new alloys or on the results of testing. They use their writing skills to communicate their findings to a variety of audiences, including engineers, scientists, and managers.

- Write technical reports on research and development work

- Write reports on the properties of new alloys

- Write reports on the results of testing

Interview Tips

Before you go on an interview, take some time to prepare. This will help you feel more confident and prepared to answer the interviewer’s questions. Here are a few tips to help you prepare for your interview:

1. Research the Company

Before you go on an interview, take some time to research the company. This will help you learn about the company’s culture, values, and goals. You can also learn about the company’s products and services. This information will help you answer the interviewer’s questions and show that you are interested in the company.

- Visit the company’s website

- Read the company’s annual report

- Talk to people who work at the company

2. Practice Answering Questions

Once you have researched the company, take some time to practice answering common interview questions. This will help you feel more confident and prepared to answer the interviewer’s questions. You can practice answering questions with a friend or family member. You can also practice answering questions in front of a mirror.

- Common interview questions include:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing a suit or business dress. You should also make sure your clothes are clean and pressed. The way you dress will show the interviewer that you are serious about the position.

- Wear a suit or business dress

- Make sure your clothes are clean and pressed

- Polish your shoes

4. Be on Time

Punctuality is important, so be on time for your interview. This means arriving at the interview location at least 10 minutes early. If you are late, the interviewer may think that you are not interested in the position. The timeliness will show that you respect the interviewer’s time too.

- Arrive at the interview location at least 10 minutes early

- If you are running late, call the interviewer to let them know

- If you are stuck in traffic, park your car and walk to the interview location

5. Be Yourself

The most important thing is to be yourself. The interviewer wants to get to know the real you. So, don’t try to be someone you’re not. Just be yourself and let the interviewer see what you have to offer.

- Be honest and forthcoming

- Don’t try to be someone you’re not

- Let the interviewer see the real you

Next Step:

Now that you’re armed with the knowledge of Metal Alloy Scientist interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal Alloy Scientist positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini