Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal and Plastic Combination Machine Tool Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

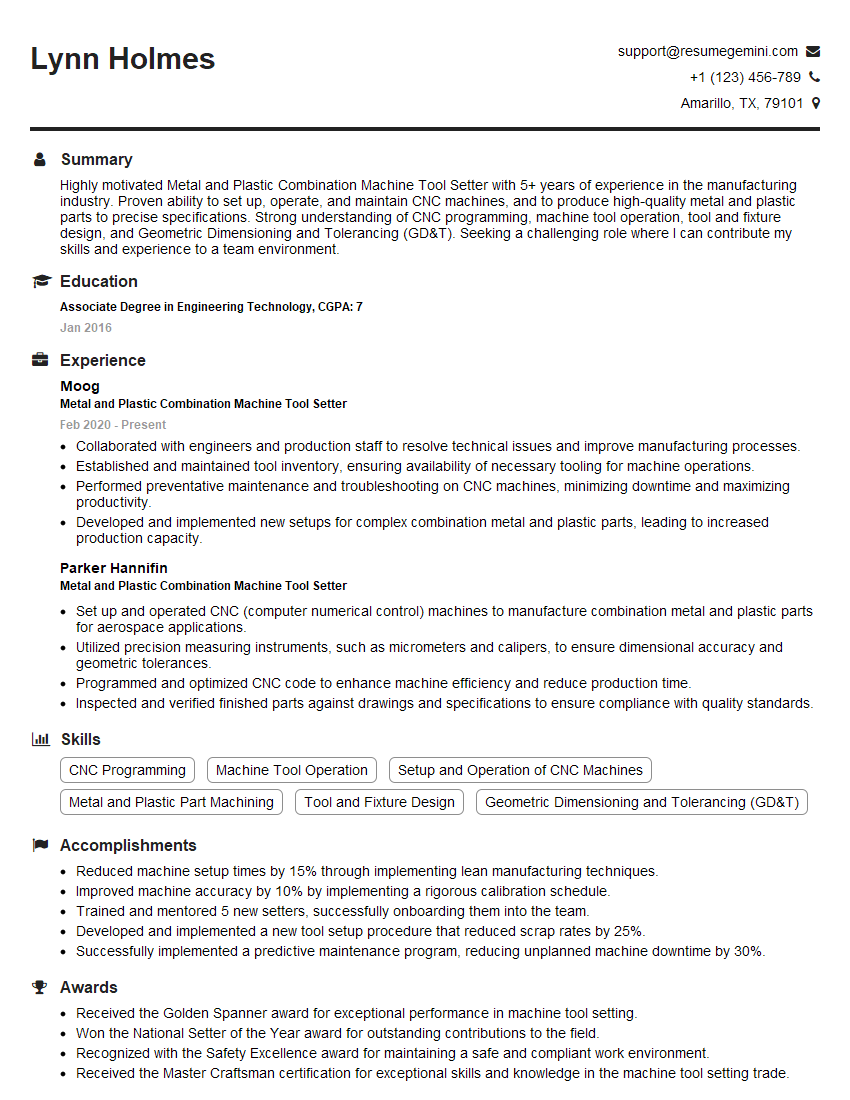

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal and Plastic Combination Machine Tool Setter

1. What are the key differences between metal and plastic combination machine tools and conventional machine tools?

Metal and plastic combination machine tools are more versatile than conventional machine tools as they can process both metal and plastic materials. They provide the benefits of both metalworking and plastic processing in a single machine. In addition to standard metalworking operations, they offer additional capabilities such as cutting, shaping, and forming plastics, making them ideal for producing complex parts that require both metal and plastic components.

2. How do you ensure the accuracy and precision of metal and plastic combination machine tools?

Calibration and Maintenance

- Regularly calibrate the machine according to the manufacturer’s specifications to maintain accuracy.

- Perform preventive maintenance to ensure all components are functioning correctly.

Tooling and Workholding

- Use sharp and appropriate cutting tools for the specific materials being processed.

- Securely clamp the workpiece to minimize vibration and prevent inaccuracies.

Environmental Conditions

- Control temperature and humidity in the operating environment to minimize thermal expansion.

- Protect the machine from vibration and other external factors that could affect accuracy.

3. What are the different types of CNC controls used in metal and plastic combination machine tools?

There are various types of CNC controls used in metal and plastic combination machine tools. Some common types include:

- Proprietary controls: Developed and supplied by the machine manufacturer.

- Third-party controls: Provided by independent companies and can be used on different machine brands.

- Open-source controls: Freely available and customizable, allowing for greater flexibility.

- Industrial PCs: High-performance computers used for complex control and automation tasks.

4. How do you troubleshoot common problems encountered in metal and plastic combination machine tools?

Mechanical Issues

- Check for loose connections, worn components, or mechanical misalignments.

- Inspect the lubrication system to ensure proper lubrication.

Electrical Issues

- Inspect electrical connections, wiring, and circuit breakers.

- Check for voltage fluctuations or power outages.

Software Issues

- Verify that the CNC program is error-free and compatible with the machine’s control system.

- Check for software updates or patches that may resolve issues.

5. What is the importance of proper coolant management in metal and plastic combination machine tools?

- Cooling and lubrication: Coolant prevents overheating of cutting tools and the workpiece, reducing friction and wear.

- Chip removal: Coolant helps flush away chips and debris from the cutting area, improving surface finish.

- Corrosion prevention: Coolant containing additives can protect metal parts from corrosion.

- Tool life extension: Proper coolant management can prolong the life of cutting tools by reducing heat and wear.

6. How do you handle the transition between metalworking and plastic processing operations on a metal and plastic combination machine tool?

- Change tooling: Replace metalworking tools with plastic processing tools.

- Adjust machine parameters: Modify cutting speeds, feed rates, and coolant settings to suit plastic materials.

- Clean the machine: Remove any metal chips or debris from the cutting area to prevent contamination of plastic parts.

- Inspect the workpiece: Ensure that the transition between materials is smooth, with no burrs or imperfections.

7. What safety precautions should be taken when operating metal and plastic combination machine tools?

- Wear appropriate safety gear, including eye protection, gloves, and protective clothing.

- Ensure the machine is properly grounded and electrically safe.

- Keep the work area clean and free of obstructions.

- Be aware of moving parts and rotating tools.

- Follow lockout/tagout procedures when servicing or maintaining the machine.

8. What is the role of CAM software in programming metal and plastic combination machine tools?

- Generate CNC programs from 3D models: CAM software converts design models into CNC instructions.

- Toolpath optimization: CAM software calculates efficient toolpaths to minimize cycle times and improve part quality.

- Simulation and verification: CAM software allows for simulation of toolpaths to identify potential issues.

- Post-processing: CAM software generates CNC code compatible with specific machine controls.

9. How do you stay up-to-date with advancements in metal and plastic combination machine tools and technologies?

- Attend industry trade shows and conferences.

- Read technical publications and articles.

- Participate in online forums and discussion groups.

- Take training courses offered by machine manufacturers or technical institutions.

10. What qualities make an effective metal and plastic combination machine tool setter?

- Strong technical skills and understanding of machining principles.

- Proficiency in CNC programming and operation.

- Ability to troubleshoot and resolve technical issues.

- Attention to detail and a commitment to accuracy.

- Effective communication and teamwork skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal and Plastic Combination Machine Tool Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal and Plastic Combination Machine Tool Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal and Plastic Combination Machine Tool Setters are responsible for setting up, operating, and maintaining metal and plastic combination machine tools. They ensure that the tools are functioning properly and producing high-quality products. Some of the key responsibilities include:

1. Setting up and operating machine tools

Set up and operate metal and plastic combination machine tools to produce parts according to specifications

- Interpret blueprints and other technical documents to determine the required settings for the machine tools

- Select and install the appropriate tooling and fixtures

- Adjust the machine tools to the correct speeds and feeds

- Monitor the operation of the machine tools to ensure that they are producing parts to the correct specifications

2. Maintaining machine tools

Perform preventive maintenance on metal and plastic combination machine tools to keep them in good working order

- Lubricate and clean the machine tools

- Inspect the machine tools for wear and tear

- Repair or replace worn or damaged parts

- Calibrate the machine tools to ensure that they are accurate

3. Troubleshooting problems

Troubleshoot problems with metal and plastic combination machine tools to ensure that they are operating properly

- Identify the cause of the problem

- Repair or replace the damaged parts

- Adjust the machine tools to the correct settings

- Test the machine tools to ensure that they are operating properly

4. Working with other departments

Work with other departments to ensure that the metal and plastic combination machine tools are producing parts to the correct specifications

- Communicate with engineers to discuss the design of the parts

- Coordinate with production to ensure that the parts are produced on time

- Provide feedback to management on the performance of the machine tools

Interview Tips

To ace the interview for a Metal and Plastic Combination Machine Tool Setter position, it is important to prepare thoroughly and practice answering common interview questions. Here are a few tips:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information on the company’s website, LinkedIn, and other online sources.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

3. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience in setting up and operating metal and plastic combination machine tools. Be prepared to discuss your experience in detail, including the specific types of machines you have worked with and the types of parts you have produced. You should also be able to discuss your troubleshooting skills and your experience in working with other departments.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the position and who is positive about their ability to do the job. Be sure to show your enthusiasm and positivity throughout the interview. You should also be prepared to answer questions about your career goals and your aspirations for the future.

5. Be prepared to ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the position and the company. Be prepared to ask thoughtful questions that show your interest in the position and your commitment to the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal and Plastic Combination Machine Tool Setter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.