Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal and Plastic Heater interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal and Plastic Heater so you can tailor your answers to impress potential employers.

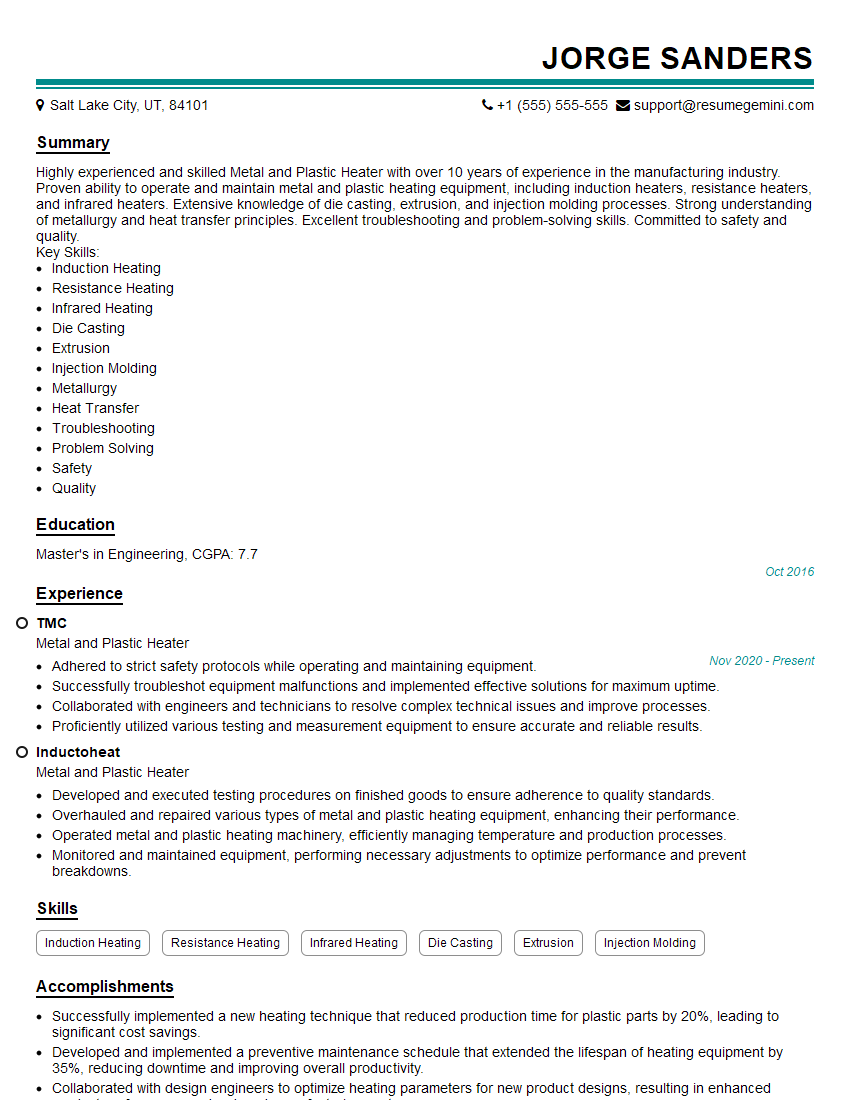

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal and Plastic Heater

1. What are the different types of metal and plastic heaters?

There are many different types of metal and plastic heaters, each with its own unique advantages and disadvantages. Some of the most common types include:

- Resistance heaters: These heaters use a resistive element to generate heat. They are simple to design and build, but they can be less efficient than other types of heaters.

- Induction heaters: These heaters use electromagnetic induction to generate heat. They are very efficient, but they can be more expensive than other types of heaters.

- Infrared heaters: These heaters emit infrared radiation, which is absorbed by objects and converted into heat. They are very efficient and can be used to heat large areas.

- Microwave heaters: These heaters use microwaves to generate heat. They are very fast and efficient, but they can be more expensive than other types of heaters.

2. What are the factors that affect the performance of a metal and plastic heater?

Factors affecting metal heater performance

- Material properties: The thermal conductivity, specific heat, and emissivity of the metal will all affect its ability to heat up and cool down.

- Heater design: The shape, size, and surface area of the heater will all affect its ability to transfer heat to the metal.

- Operating conditions: The temperature, pressure, and flow rate of the fluid being heated will all affect the performance of the heater.

Factors affecting plastic heater performance

- Material properties: The thermal conductivity, specific heat, and melting point of the plastic will all affect its ability to heat up and cool down.

- Heater design: The shape, size, and surface area of the heater will all affect its ability to transfer heat to the plastic.

- Operating conditions: The temperature, pressure, and flow rate of the fluid being heated will all affect the performance of the heater.

3. How can you troubleshoot a metal and plastic heater?

Troubleshooting a metal and plastic heater involves a systematic approach to identify and resolve any issues that may arise. The following steps can be followed:

- Check the power supply to the heater to ensure that it is receiving power.

- Inspect the heater for any visible damage, such as loose wires or broken components.

- Measure the temperature of the heater using a thermometer or other temperature-measuring device to ensure that it is heating up to the desired temperature.

- Check the flow rate of the fluid being heated to ensure that it is within the specified range.

- If the heater is not heating up properly, check the heating element for any damage or wear.

- If the heater is overheating, check for any blockages in the flow of the fluid or any other factors that may be causing the heater to overheat.

4. What are the safety precautions that should be taken when working with metal and plastic heaters?

When working with metal and plastic heaters, it is important to take the following safety precautions:

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Be aware of the potential for burns and take precautions to avoid contact with hot surfaces.

- Do not operate heaters in the presence of flammable materials.

- Ensure that heaters are properly grounded to prevent electrical shock.

- Follow all manufacturer instructions for the safe operation of the heater.

5. What are the applications of metal and plastic heaters?

Metal and plastic heaters have a wide range of applications in various industries, including:

- Industrial processes: Metal and plastic heaters are used in a variety of industrial processes, such as metal forming, plastic molding, and heat treating.

- Consumer products: Metal and plastic heaters are used in a variety of consumer products, such as hair dryers, space heaters, and ovens.

- Medical applications: Metal and plastic heaters are used in a variety of medical applications, such as surgical instruments, medical imaging equipment, and patient warming.

6. What are the advantages and disadvantages of using metal and plastic heaters?

Advantages of using metal and plastic heaters:

- High efficiency: Metal and plastic heaters are very efficient at transferring heat to the target material.

- Durability: Metal and plastic heaters are durable and can withstand high temperatures and harsh conditions.

- Compact size: Metal and plastic heaters are relatively compact and can be easily integrated into various applications.

- Cost-effectiveness: Metal and plastic heaters are relatively cost-effective compared to other heating methods.

Disadvantages of using metal and plastic heaters:

- Safety concerns: Metal and plastic heaters can pose safety concerns, such as the risk of burns or electrical shock.

- Maintenance requirements: Metal and plastic heaters require regular maintenance to ensure optimal performance and safety.

- Limited temperature range: Metal and plastic heaters may have limited temperature ranges compared to other heating methods.

7. What are the latest trends in metal and plastic heater technology?

The latest trends in metal and plastic heater technology include:

- Increased use of advanced materials: Advanced materials, such as graphene and carbon nanotubes, are being used to improve the thermal conductivity and efficiency of metal and plastic heaters.

- Development of new heater designs: New heater designs, such as flexible heaters and 3D printed heaters, are being developed to meet the specific requirements of various applications.

- Integration of sensors and controls: Sensors and controls are being integrated into metal and plastic heaters to improve temperature control and energy efficiency.

8. What are the challenges in the design and manufacturing of metal and plastic heaters?

The design and manufacturing of metal and plastic heaters pose several challenges, including:

- Material selection: Selecting the right materials for the heater is crucial to ensure its performance, durability, and safety.

- Heat transfer optimization: Designing the heater to optimize heat transfer while minimizing energy loss is a key challenge.

- Safety considerations: Ensuring the safety of the heater during operation and handling is a top priority.

- Cost-effective manufacturing: Balancing the performance and cost of the heater is essential for commercial success.

9. How do you stay up-to-date with the latest advancements in metal and plastic heater technology?

To stay up-to-date with the latest advancements in metal and plastic heater technology, I employ the following strategies:

- Attend industry conferences and workshops: These events provide valuable opportunities to learn about new technologies and network with experts in the field.

- Read technical journals and articles: Staying informed through reputable publications ensures access to the latest research and development findings.

- Engage with industry professionals: Connecting with peers and colleagues allows for the exchange of knowledge and insights.

- Participate in online forums and discussion groups: These platforms facilitate discussions and the sharing of information related to the industry.

10. What are your career goals and how do you see this role contributing to your professional development?

My career goals revolve around contributing to the advancement of metal and plastic heater technology. I am particularly interested in exploring the use of novel materials and innovative designs to improve the efficiency and safety of these devices. This role aligns with my aspirations as it provides an opportunity to work on cutting-edge projects and collaborate with experienced professionals in the field. Through hands-on experience and mentorship, I am confident that I can make meaningful contributions to the company and further develop my skills in the field of metal and plastic heater technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal and Plastic Heater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal and Plastic Heater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal and Plastic Heater is a skilled professional who operates and maintains machinery that heats and shapes metal and plastic materials. They work in a variety of industries, including manufacturing, automotive, and construction.

1. Operate and maintain machinery

Metal and Plastic Heaters are responsible for operating and maintaining a variety of machinery, including furnaces, ovens, and presses. They must be able to troubleshoot and repair machinery, as well as make adjustments to ensure that the equipment is operating properly.

2. Heat and shape metal and plastic

Metal and Plastic Heaters use heat to shape and form metal and plastic materials. They must be able to control the temperature and pressure of the equipment to achieve the desired results.

3. Inspect finished products

Metal and Plastic Heaters inspect finished products to ensure that they meet specifications. They must be able to identify defects and take corrective action.

4. Follow safety procedures

Metal and Plastic Heaters must follow all safety procedures to protect themselves and others from injury. They must be aware of the hazards associated with working with hot materials and equipment.

Interview Tips

Preparing for an interview for a Metal and Plastic Heater position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company and position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in a clear and concise manner.

3. Prepare questions for the interviewer

Asking the interviewer questions is a great way to show that you are interested in the position and the company. Prepare a few questions that you can ask, such as “What are the biggest challenges facing the company right now?” or “What is the company’s culture like?”

4. Dress professionally and arrive on time

First impressions matter, so make sure to dress professionally for your interview. Arrive on time for your interview and be prepared to start on time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Metal and Plastic Heater, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Metal and Plastic Heater positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.