Are you gearing up for an interview for a Metal and Plastic Heating Equipment Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal and Plastic Heating Equipment Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

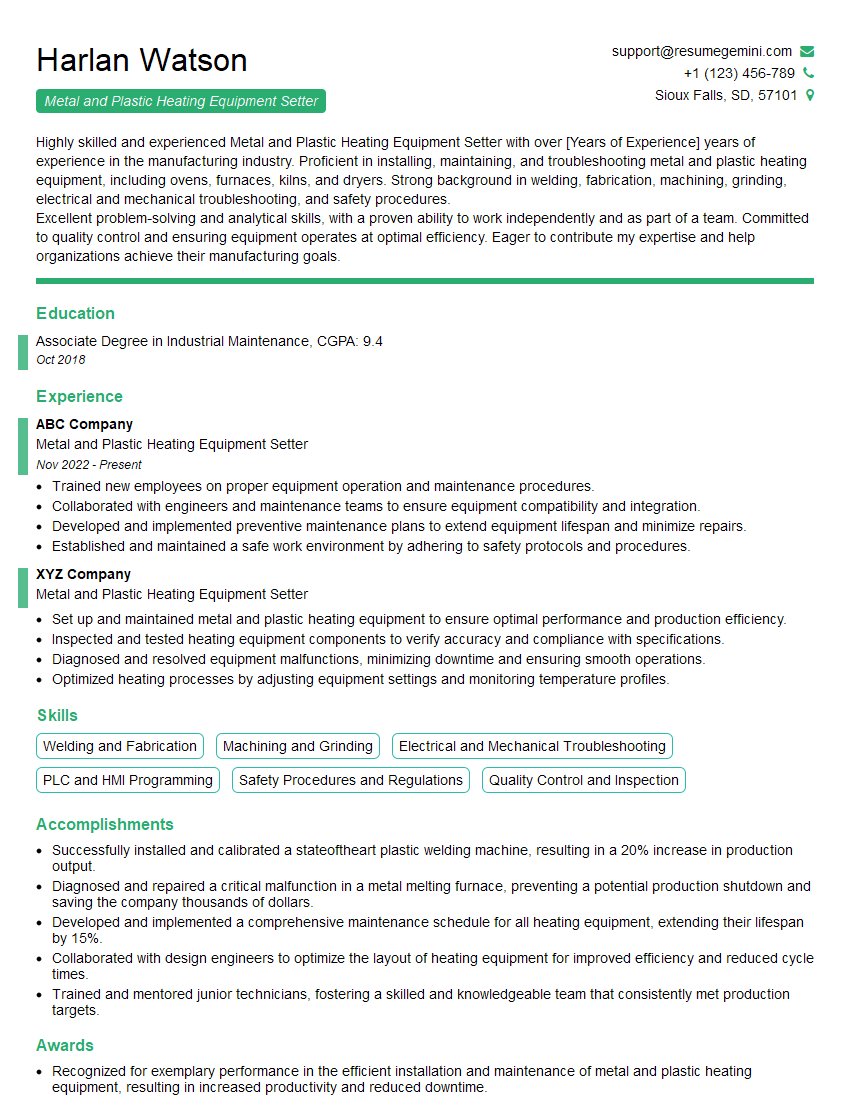

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal and Plastic Heating Equipment Setter

1. What are the different types of metal and plastic heating equipment that you are familiar with?

I am familiar with a wide range of metal and plastic heating equipment, including:

- Furnaces

- Ovens

- Kilns

- Induction heaters

- Lasers

- Plasma cutters

- Waterjet cutters

2. What are the key safety considerations when working with metal and plastic heating equipment?

Hazard Identification

- Identify potential hazards associated with the equipment, such as electrical shock, burns, and fumes.

- Assess the risks associated with each hazard and determine appropriate control measures.

Control Measures

- Use proper personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Ensure that the equipment is properly grounded and ventilated.

- Follow established safety procedures and guidelines.

Emergency Preparedness

- Know the location of fire extinguishers and first aid kits.

- Be trained in emergency response procedures.

3. How do you troubleshoot and repair common problems with metal and plastic heating equipment?

To troubleshoot and repair common problems with metal and plastic heating equipment, I follow these steps:

- Identify the problem and its potential causes.

- Inspect the equipment for any visible damage or loose connections.

- Check the electrical supply and connections.

- Test the equipment using a multimeter or other diagnostic tools.

- Replace or repair any faulty components.

- Test the equipment again to ensure that the problem has been resolved.

4. What are the different types of materials that can be heated with metal and plastic heating equipment?

The different types of materials that can be heated with metal and plastic heating equipment include:

- Metals: steel, aluminum, copper, brass, etc.

- Plastics: polyethylene, polypropylene, PVC, etc.

- Glass

- Ceramics

- Composites

5. What are the different types of heating processes that can be used with metal and plastic heating equipment?

The different types of heating processes that can be used with metal and plastic heating equipment include:

- Convection heating

- Conduction heating

- Radiation heating

- Induction heating

- Laser heating

- Plasma heating

- Waterjet cutting

6. What are the different types of quality control checks that you perform when setting up and operating metal and plastic heating equipment?

The different types of quality control checks that I perform when setting up and operating metal and plastic heating equipment include:

- Checking the equipment for proper calibration.

- Ensuring that the equipment is operating within the specified temperature range.

- Monitoring the equipment for any signs of wear or damage.

- Inspecting the finished product for any defects.

- Maintaining detailed records of all quality control checks.

7. What are the different types of maintenance tasks that you perform on metal and plastic heating equipment?

The different types of maintenance tasks that I perform on metal and plastic heating equipment include:

- Cleaning the equipment regularly.

- Lubricating moving parts.

- Inspecting the equipment for any signs of wear or damage.

- Replacing any worn or damaged parts.

- Calibrating the equipment regularly.

- Maintaining detailed records of all maintenance tasks.

8. What are the different types of safety regulations that you are familiar with for working with metal and plastic heating equipment?

The different types of safety regulations that I am familiar with for working with metal and plastic heating equipment include:

- Occupational Safety and Health Administration (OSHA) regulations

- National Fire Protection Association (NFPA) codes

- American National Standards Institute (ANSI) standards

- Company-specific safety policies and procedures

9. What are the different types of training that you have received for working with metal and plastic heating equipment?

The different types of training that I have received for working with metal and plastic heating equipment include:

- On-the-job training from experienced operators

- Classroom training from qualified instructors

- Online training modules

- Manufacturer-specific training programs

10. What are your career goals and how do you see this position helping you achieve them?

My career goal is to become a supervisor in the metal and plastic heating equipment industry. I believe that this position will help me achieve my goal by providing me with the opportunity to develop my leadership skills, gain experience in managing a team, and learn more about the technical aspects of metal and plastic heating.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal and Plastic Heating Equipment Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal and Plastic Heating Equipment Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal and Plastic Heating Equipment Setter is responsible for installing, maintaining, and repairing heating equipment used in the manufacturing of metal and plastic products. Key responsibilities include:

1. Equipment Installation and Setup

Installing and setting up heating equipment, including furnaces, ovens, and kilns.

- Ensuring that equipment is properly leveled, grounded, and connected to power and gas supplies.

- Verifying that equipment is operating safely and efficiently.

2. Equipment Maintenance and Repair

Conducting regular maintenance and repairs on heating equipment.

- Inspecting equipment for signs of wear and tear.

- Replacing worn or damaged parts.

- Calibrating equipment to ensure accuracy.

3. Process Monitoring and Control

Monitoring and controlling the heating process to ensure that products are heated to the correct temperature and for the correct amount of time.

- Using thermocouples and other instruments to measure temperature.

- Adjusting equipment settings to maintain desired temperatures.

- Ensuring that products are heated evenly and consistently.

4. Safety Compliance

Complying with all safety regulations and procedures.

- Wearing appropriate safety gear.

- Following lockout/tagout procedures.

- Reporting any safety hazards or concerns.

Interview Tips

To ace an interview for a Metal and Plastic Heating Equipment Setter position, it is important to:

1. Research the Company and Position

Learn about the company’s products, services, and culture. Research the specific role and its responsibilities.

- Visit the company’s website.

- Read industry publications.

- Talk to people who work in the field.

2. Highlight Your Skills and Experience

Emphasize your skills and experience in installing, maintaining, and repairing heating equipment. Highlight your knowledge of safety regulations and procedures.

- Quantify your accomplishments whenever possible.

- Use specific examples to demonstrate your skills.

- Tailor your resume and cover letter to the specific job requirements.

3. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about your experience installing and maintaining heating equipment.

- What are your strengths and weaknesses as a Metal and Plastic Heating Equipment Setter?

- Why are you interested in working for this company?

4. Dress Professionally and Arrive on Time

Make a good impression by dressing professionally and arriving on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal and Plastic Heating Equipment Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.