Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

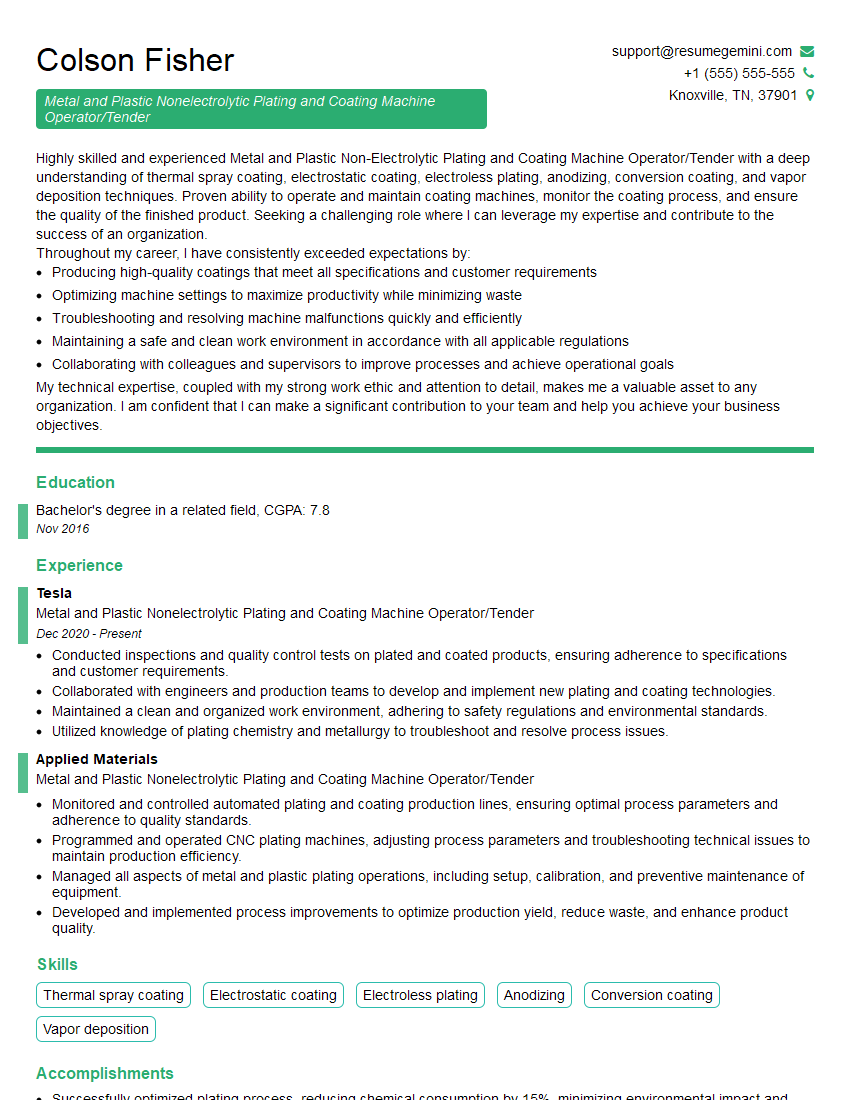

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender

1. What are the different types of non-electrolytic plating and coating processes?

There are three main types of non-electroless plating and coating processes:

- Chemical plating: In chemical plating, the metal or alloy is deposited on the substrate by a chemical reduction reaction. The reductant is typically a hypophosphite or borohydride.

- Electroless plating: In electroless plating, the metal or alloy is deposited on the substrate by a redox reaction involving a metal ion and a reducing agent. The metal ion is typically in a complex form.

- Vapor deposition: In vapor deposition, the metal or alloy is deposited on the substrate by a physical or chemical process. The metal or alloy is vaporized and then condensed onto the substrate.

2. What are the advantages and disadvantages of non-electrolytic plating and coating?

Advantages

- Non-electrolytic plating and coating processes are relatively simple and inexpensive.

- They can be used to deposit a wide variety of metals and alloys.

- They can be used to coat a variety of substrates, including metals, plastics, and ceramics.

Disadvantages

- Non-electrolytic plating and coating processes can be slow.

- They can produce deposits that are not as thick or as uniform as those produced by electrolytic plating processes.

- They can produce deposits that are not as corrosion-resistant as those produced by electrolytic plating processes.

3. What are the different types of equipment used in non-electrolytic plating and coating?

The following equipment is used in non-electrolytic plating and coating:

- Plating tanks

- Coating machines

- Chemical pumps

- Heat exchangers

- Filters

4. What are the different types of materials used in non-electrolytic plating and coating?

The following materials are used in non-electrolytic plating and coating:

- Metal salts

- Reducing agents

- Complexing agents

- Buffers

- Surfactants

5. What are the different process parameters that can be controlled in non-electrolytic plating and coating?

The following process parameters can be controlled in non-electrolytic plating and coating:

- Temperature

- pH

- Concentration of metal ions

- Concentration of reducing agents

- Concentration of complexing agents

- Concentration of buffers

- Concentration of surfactants

6. What are the different quality control tests that can be performed on non-electrolytic plated and coated products?

The following quality control tests can be performed on non-electrolytic plated and coated products:

- Thickness testing

- Adhesion testing

- Corrosion testing

- Hardness testing

- Electrical testing

7. What are the different safety precautions that must be taken when working with non-electrolytic plating and coating chemicals?

The following safety precautions must be taken when working with non-electrolytic plating and coating chemicals:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area.

- Do not ingest or inhale chemicals.

- Do not mix chemicals unless you are specifically instructed to do so.

- Dispose of chemicals properly.

8. What are the different troubleshooting techniques that can be used to solve problems with non-electrolytic plating and coating processes?

The following troubleshooting techniques can be used to solve problems with non-electrolytic plating and coating processes:

- Check the process parameters to make sure they are within the specified range.

- Check the equipment to make sure it is functioning properly.

- Check the materials to make sure they are of the correct type and concentration.

- Check the substrate to make sure it is clean and free of contaminants.

- Check the process sequence to make sure it is correct.

9. What are the different career opportunities for people with experience in non-electrolytic plating and coating?

People with experience in non-electrolytic plating and coating can work in a variety of industries, including:

- Automotive industry

- Aerospace industry

- Electronics industry

- Medical device industry

10. What are your long-term career goals?

My long-term career goal is to become a manager in the plating and coating industry. I want to use my knowledge and experience to help my company develop and produce high-quality products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal and Plastic Nonelectrolytic Plating and Coating Machine Operators/Tenders play a crucial role in the production process, ensuring the proper coating and plating of metal and plastic surfaces. Their responsibilities include meticulously adhering to established procedures and operating sophisticated machinery to achieve the desired results. Here are some key responsibilities of the role:

1. Machine Operation

Expertly operate and monitor nonelectrolytic plating and coating machines, ensuring optimal functioning and compliance with established process parameters.

- Adjust and calibrate machine settings to achieve precise coating and plating specifications.

- Load and unload workpieces, adhering to safety protocols and maintaining efficient production flow.

2. Process Monitoring

Continuously monitor the plating and coating processes, vigilantly observing indicators such as temperature, pressure, and chemical composition.

- Conduct regular inspections of workpieces to ensure adherence to quality standards and specifications.

- Identify and promptly address any deviations from established process parameters, taking corrective actions as needed.

3. Equipment Maintenance

Perform basic maintenance and troubleshooting tasks on plating and coating machines, minimizing downtime and ensuring smooth operations.

- Clean and lubricate equipment as per established schedules.

- Identify and report any mechanical or electrical issues to supervisors promptly.

4. Safety and Compliance

Uphold stringent safety standards and adhere to all applicable environmental regulations throughout the plating and coating processes.

- Wear appropriate personal protective equipment (PPE) to minimize exposure to hazardous chemicals.

- Follow established waste disposal procedures, ensuring compliance with environmental regulations.

Interview Tips

Preparing thoroughly for an interview is crucial to showcasing your skills and making a positive impression on potential employers. Here are some tips to help you ace your interview for a Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender position:

1. Research the Company and Role

Familiarize yourself with the company’s background, products, and industry standing. Thoroughly review the job description to understand the specific responsibilities and qualifications required for the role. This knowledge will enable you to tailor your answers and demonstrate your alignment with the company’s needs.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating nonelectrolytic plating and coating machines and your understanding of the underlying processes. Quantify your accomplishments whenever possible, providing specific examples of how you contributed to production efficiency or quality improvements in previous roles.

3. Demonstrate Safety Awareness

Plating and coating processes involve handling potentially hazardous chemicals and equipment. Highlight your commitment to safety by describing your experience in adhering to safety protocols and preventing accidents. Mention any safety certifications or training you have received, as this will demonstrate your dedication to maintaining a safe work environment.

4. Prepare for Technical Questions

Anticipate technical questions about plating and coating processes. Study the basics of these processes, including the different types of coatings, their applications, and the factors that affect coating quality. Be prepared to discuss your understanding of the process parameters and how you would troubleshoot common issues.

5. Practice Your Communication Skills

Effective communication is essential for conveying your qualifications and enthusiasm clearly. Practice answering common interview questions out loud, focusing on articulating your thoughts concisely and confidently. Remember to maintain eye contact, actively listen to the interviewer’s questions, and ask thoughtful questions of your own to show your engagement and interest in the role.

Next Step:

Now that you’re armed with the knowledge of Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini