Are you gearing up for an interview for a Metal and Plastic Sawing Machine Tool Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal and Plastic Sawing Machine Tool Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

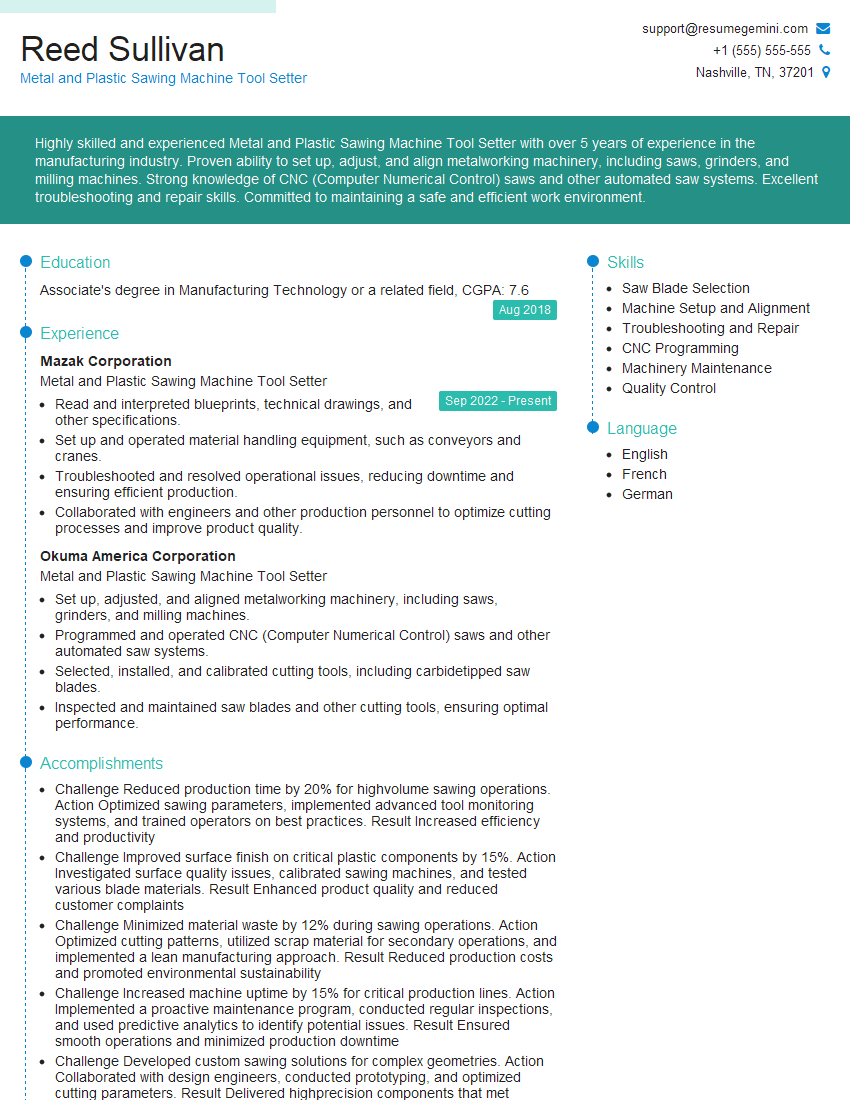

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal and Plastic Sawing Machine Tool Setter

1. Describe the key responsibilities of a Metal and Plastic Sawing Machine Tool Setter?

- Set up, adjust, and maintain metal and plastic sawing machines to cut materials accurately.

- Inspect and verify the quality of produced parts to ensure they meet specifications.

- Troubleshoot and resolve any problems that arise with the equipment or processes.

- Develop and implement processes to improve efficiency and productivity.

- Maintain a clean and organized work area.

2. What are the different types of sawing machines used in metal and plastic cutting, and what are their applications?

Types of sawing machines

- Band saws: Cutting curves and contours in metal and plastic.

- Circular saws: Straight cuts in metal and plastic.

- Jigsaw: Cutting intricate shapes in metal and plastic.

- Reciprocating saws: Cutting straight or curved lines in metal and plastic.

- Hacksaws: Cutting metal and plastic pipes and tubes.

Applications

- Automotive industry: Cutting car parts and components.

- Construction industry: Cutting metal and plastic pipes and beams.

- Aerospace industry: Cutting lightweight metal alloys for aircraft components.

- Manufacturing industry: Cutting metal and plastic components for various products.

3. Explain the process of setting up a sawing machine for a specific cutting operation, including blade selection, feed rate, and cutting speed.

- Determine the type of material and thickness to be cut.

- Select the appropriate saw blade based on the material and desired cut quality.

- Set the feed rate and cutting speed according to the blade specifications and material properties.

- Secure the material to the cutting table and align it with the blade.

- Start the machine and monitor the cutting process, making adjustments as needed.

4. How do you maintain the accuracy and precision of sawing machines?

- Regularly clean and lubricate the machine components.

- Inspect and replace worn or damaged blades.

- Calibrate the machine’s sensors and measuring devices.

- Use precision measuring tools to ensure accurate cuts.

- Follow recommended maintenance schedules and procedures.

5. Describe the different types of cutting fluids and their applications in metal and plastic sawing.

- Water-based cutting fluids: Cooling and lubricating the cutting zone, preventing overheating and extending blade life.

- Oil-based cutting fluids: Providing lubrication and cooling, suitable for heavy-duty cutting operations.

- Synthetic cutting fluids: Combining the advantages of water-based and oil-based fluids, offering improved cooling and lubrication.

- Solid lubricants: Used in dry cutting applications, reducing friction and wear.

6. How do you troubleshoot and resolve common problems that occur with sawing machines?

- Identify the problem by observing symptoms and error codes.

- Check for loose connections, worn parts, or damaged components.

- Refer to technical manuals and manufacturer’s guidelines for troubleshooting procedures.

- Replace faulty parts, adjust settings, or perform maintenance tasks to resolve the issue.

- Test the machine after repairs to ensure proper operation.

7. What safety precautions must be taken when operating sawing machines?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Ensure the machine is properly grounded and guarded.

- Keep the work area clean and free of debris.

- Be aware of the machine’s moving parts and potential hazards.

- Follow all operating instructions and safety protocols.

8. What quality control procedures do you follow to ensure the accuracy and quality of cut parts?

- Inspect the raw material before cutting to ensure it meets specifications.

- Set up the machine according to the specified cutting parameters.

- Monitor the cutting process and make adjustments as needed.

- Inspect the finished parts to ensure they meet dimensional and quality requirements.

- Maintain records of quality control checks and take corrective actions if necessary.

9. How do you stay updated on the latest advancements and technologies in sawing machines?

- Attend industry trade shows and conferences.

- Read technical journals and articles.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and discussions.

- Take training courses to enhance skills and knowledge.

10. How do you demonstrate your attention to detail and accuracy in your work as a Metal and Plastic Sawing Machine Tool Setter?

- Paying meticulous attention to machine setup and calibration.

- Thoroughly inspecting materials and parts before and after processing.

- Adhering to established quality control procedures and specifications.

- Identifying and correcting errors promptly to minimize waste.

- Maintaining a clean and organized work area to reduce the risk of mistakes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal and Plastic Sawing Machine Tool Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal and Plastic Sawing Machine Tool Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Metal and Plastic Sawing Machine Tool Setter is a skilled professional responsible for setting up and maintaining sawing machines used to cut metal and plastic materials. They ensure that the machines operate efficiently and produce high-quality products.

1. Machine Setup and Calibration

Set up, calibrate, and adjust sawing machines according to specified tolerances and requirements.

- Install and align saw blades, guides, and other components.

- Set cutting parameters such as speed, feed rate, and depth of cut.

2. Operation Monitoring

Monitor and control the operation of sawing machines to ensure efficient production.

- Observe cutting processes, material feed, and machine performance.

- Identify and correct any deviations from specified parameters.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting to keep sawing machines in optimal condition.

- Inspect and clean machines regularly.

- Lubricate and replace worn or damaged parts.

- Identify and resolve operational issues.

4. Quality Assurance

Inspect and measure cut materials to ensure they meet required specifications.

- Use measuring tools, gauges, and other equipment to verify accuracy.

- Reject defective parts and recommend corrective actions.

Interview Tips

To prepare for an interview for the Metal and Plastic Sawing Machine Tool Setter position, you can follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and culture. Research the specific job description to understand the key responsibilities and requirements.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your skills in machine setup, operation, maintenance, and troubleshooting. Quantify your experience whenever possible, using specific examples of projects or accomplishments.

3. Demonstrate Safety Knowledge

Understand and emphasize your commitment to workplace safety. Highlight your experience with following safety protocols, using personal protective equipment, and maintaining a clean and organized work area.

4. Prepare for Technical Questions

Be prepared to answer questions about sawing machine types, cutting techniques, and troubleshooting procedures. Review common industry terminology and concepts to demonstrate your technical knowledge.

5. Practice Your Communication Skills

Practice answering interview questions clearly and concisely. Prepare examples of your problem-solving abilities and how you handle challenges in the workplace. Communicate your passion for working with machinery and your attention to detail.

Next Step:

Now that you’re armed with the knowledge of Metal and Plastic Sawing Machine Tool Setter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal and Plastic Sawing Machine Tool Setter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini