Are you gearing up for an interview for a Metal and Plastic Shear and Slitter Machine Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal and Plastic Shear and Slitter Machine Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

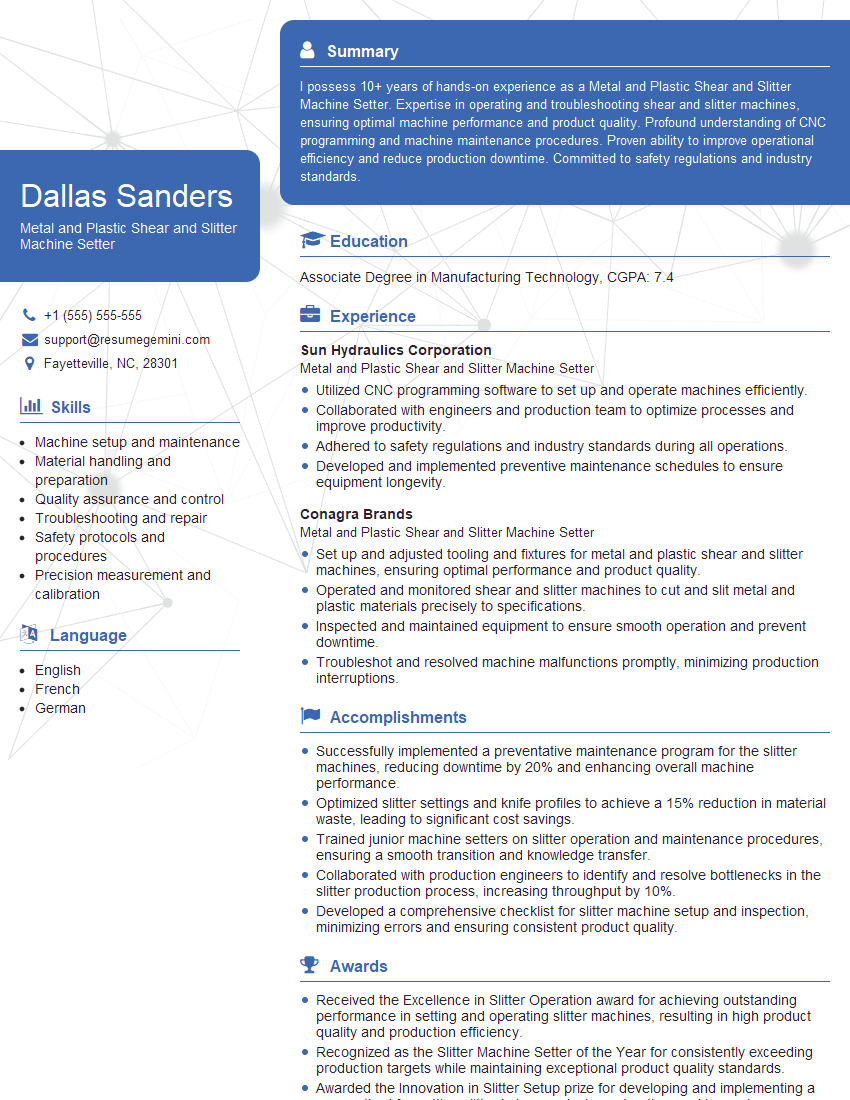

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal and Plastic Shear and Slitter Machine Setter

1. What are the key responsibilities of a Metal and Plastic Shear and Slitter Machine Setter?

- Set up, adjust, and maintain metal and plastic shear and slitter machines to ensure optimal performance.

- Inspect and measure materials to determine appropriate settings for shear and slitter machines.

- Monitor machine operations and make adjustments as needed to maintain production and quality standards.

- Troubleshoot and resolve machine malfunctions to minimize downtime and ensure efficient operations.

- Maintain a clean and organized work area, adhering to safety protocols and industry regulations.

2. What are the different types of shear and slitter machines?

subheading of the answer

- Guillotine shears: Used for straight cuts on metal and plastic sheets.

- Rotary shears: Used for cutting curves and irregular shapes on metal and plastic sheets.

- Slitters: Used for cutting metal and plastic sheets into narrow strips.

subheading of the answer

- Horizontal slitter: The material is fed horizontally through the machine, and the slitting blades are mounted on a rotating shaft.

- Vertical slitter: The material is fed vertically through the machine, and the slitting blades are mounted on a vertical shaft.

- Combination shear and slitter: Combines the functions of both a shear and a slitter, allowing for both straight and slit cuts on metal and plastic sheets.

3. What are the safety precautions that must be taken when operating shear and slitter machines?

- Always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection.

- Ensure that the machine is properly grounded and all guards are in place before operating.

- Never reach into the cutting area while the machine is running.

- Keep the work area clean and free of debris to prevent slipping or tripping hazards.

- Be aware of the location of emergency stop buttons and use them immediately if necessary.

4. What are the common causes of shear and slitter machine downtime?

- Dull or damaged blades

- Improper machine setup

- Material feeding issues

- Electrical or mechanical faults

- Lack of proper maintenance

5. How do you troubleshoot and resolve a shear or slitter machine that is not cutting properly?

- Check the blades for dullness or damage and replace if necessary.

- Inspect the material and ensure that it is the correct thickness and type for the machine.

- Verify that the machine is set up correctly for the desired cut.

- Check for any electrical or mechanical faults that may be causing the issue.

- Perform regular maintenance and lubrication to prevent future problems.

6. What are the key performance indicators (KPIs) for a Metal and Plastic Shear and Slitter Machine Setter?

- Machine uptime and efficiency

- Product quality and accuracy

- Production output and throughput

- Material yield and waste minimization

- Safety compliance and incident prevention

7. How do you stay up-to-date on the latest advancements in shearing and slitting technology?

- Attend industry conferences and trade shows.

- Read industry publications and white papers.

- Connect with other professionals in the field.

- Participate in online forums and webinars.

- Receive training from equipment manufacturers.

8. What is your experience with using computerized numerical control (CNC) systems?

- Experience programming and operating CNC shear and slitter machines.

- Familiarity with different CNC software and controllers.

- Ability to create and optimize CNC programs for efficient and accurate cutting operations.

9. What are some of the challenges you have faced as a Metal and Plastic Shear and Slitter Machine Setter?

- Setting up and maintaining complex machines to meet tight tolerances.

- Troubleshooting and resolving machine malfunctions under time pressure.

- Working in a fast-paced and demanding production environment.

- Ensuring the safety of oneself and others while operating heavy machinery.

- Staying up-to-date with the latest technological advancements.

10. Why are you interested in working as a Metal and Plastic Shear and Slitter Machine Setter in our company?

- Interest in contributing to the manufacturing industry by ensuring efficient and precise cutting operations.

- Desire to work with advanced machinery and technology.

- Attracted by the opportunity to work in a fast-paced and challenging environment.

- Belief that my skills and experience will be a valuable asset to the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal and Plastic Shear and Slitter Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal and Plastic Shear and Slitter Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal and Plastic Shear and Slitter Machine Setters are responsible for the setup, operation, and maintenance of metal and plastic shear and slitter machines. They must be able to read and interpret blueprints and specifications, and have a strong understanding of the principles of shearing and slitting. Key responsibilities include:

1. Set up and operate shear and slitter machines

Set up and operate shear and slitter machines to cut metal and plastic into specified shapes and sizes.

- Read and interpret blueprints and specifications to determine the required cuts.

- Select the appropriate tooling and set up the machine accordingly.

- Operate the machine to cut the metal or plastic to the specified dimensions.

2. Inspect and maintain shear and slitter machines

Inspect and maintain shear and slitter machines to ensure they are operating properly and safely.

- Check the machine for wear and tear.

- Lubricate and adjust the machine as needed.

- Troubleshoot and repair any problems that may occur.

3. Train and supervise other workers

Train and supervise other workers on the proper use of shear and slitter machines.

- Instruct workers on the safe operation of the machines.

- Monitor the work of other workers to ensure they are following proper procedures.

- Provide feedback and guidance to other workers.

4. Maintain a safe work environment

Maintain a safe work environment by following all safety regulations.

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Keep the work area clean and free of debris.

- Report any unsafe conditions to a supervisor.

Interview Tips

Preparing for an interview for a Metal and Plastic Shear and Slitter Machine Setter position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you’re applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, social media pages, and Glassdoor. You can also find information about the specific position by reading the job description.

2. Practice answering common interview questions

There are a number of common interview questions that you’re likely to be asked, regardless of the position you’re applying for. It’s a good idea to practice answering these questions before the interview so that you can deliver clear and concise answers. Some common interview questions include:

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- What are your career goals?

3. Prepare questions to ask the interviewer

Asking questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the next year?

- What is the company’s culture like?

- What are the opportunities for advancement within the company?

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for the interview. You should also arrive on time for the interview. Punctuality shows that you’re respectful of the interviewer’s time.

5. Be yourself and be confident

The most important thing is to be yourself and be confident. The interviewer will be able to tell if you’re being genuine, so don’t try to be someone you’re not. Just relax, be yourself, and let your personality shine through.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal and Plastic Shear and Slitter Machine Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.