Are you gearing up for a career in Metal Annealer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Annealer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

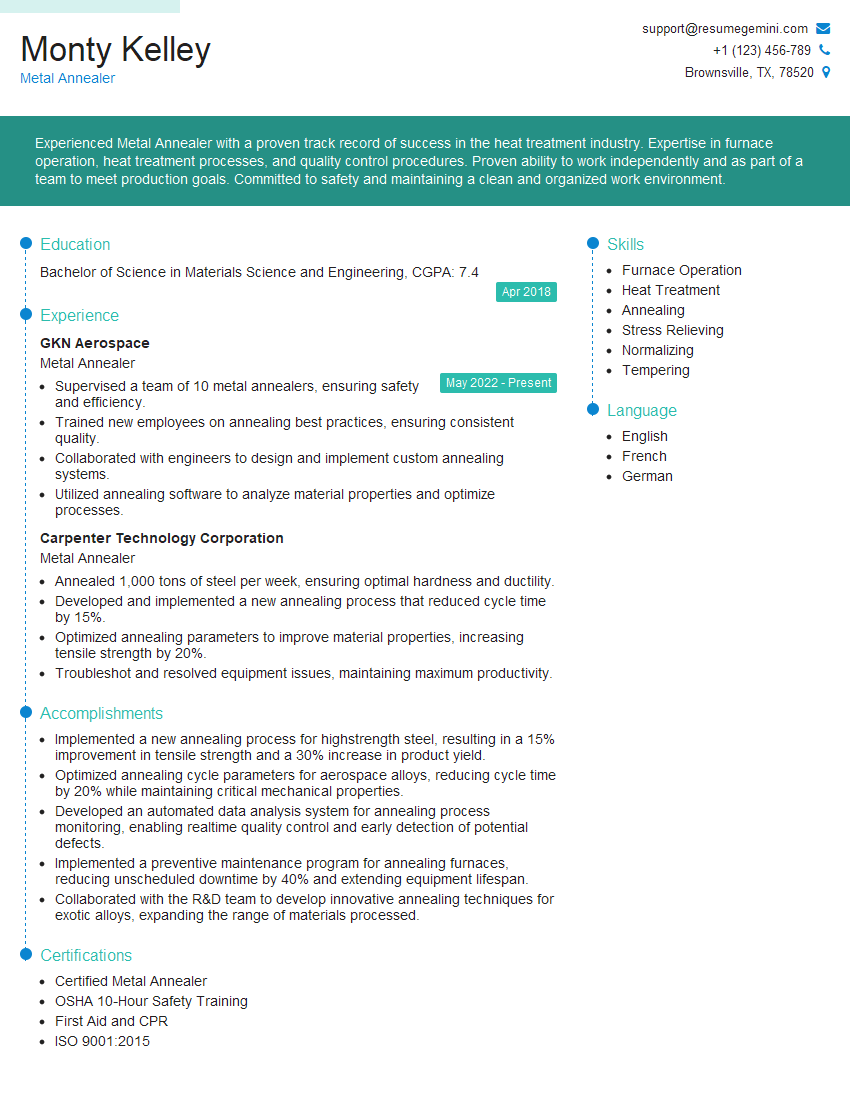

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Annealer

1. What are the different types of annealing processes used for metals, and how do they differ?

Annealing is a heat treatment process that alters the physical and mechanical properties of a metal by heating it to a specific temperature and then cooling it slowly. There are three main types of annealing processes:

- Process Annealing: Involves heating the metal to a temperature just below its melting point and holding it there for a period of time. This process softens the metal and makes it more ductile.

- Full Annealing: Similar to process annealing, but the metal is heated to a higher temperature, typically above its critical temperature. This process produces a softer and more ductile metal than process annealing.

- Stress Relief Annealing: Involves heating the metal to a temperature below its recrystallization temperature and holding it there for a period of time. This process relieves internal stresses in the metal, making it less brittle and more resistant to cracking.

2. Explain the process of normalizing in annealing.

Normalizing is a heat treatment process that involves heating the metal to a temperature above its critical temperature and then cooling it in still air. This process produces a metal with a fine-grained structure that is stronger and harder than annealed metal.

Benefits of Normalizing:

- Improves the strength and hardness of the metal

- Produces a more uniform grain structure

- Reduces internal stresses

Applications of Normalizing:

- Forgings and castings

- Steel plates and bars

- Automotive components

3. What are the effects of annealing on the microstructure and properties of metals?

Annealing can significantly alter the microstructure and properties of metals. The effects of annealing on the microstructure include:

- Grain Growth: Annealing can cause grain growth, which increases the average grain size of the metal.

- Recrystallization: Annealing can cause recrystallization, which is the formation of new grains with a different orientation than the original grains.

- Phase Transformation: Annealing can cause phase transformations, such as the transformation of austenite to ferrite in steel.

The effects of annealing on the properties of metals include:

- Hardness: Annealing generally decreases the hardness of metals.

- Strength: Annealing generally decreases the strength of metals.

- Ductility: Annealing generally increases the ductility of metals.

- Toughness: Annealing generally increases the toughness of metals.

4. How do you determine the appropriate annealing temperature for a given metal?

The appropriate annealing temperature for a given metal depends on several factors, including:

- The type of metal

- The desired properties

- The thickness of the metal

- The annealing equipment

The annealing temperature can be determined by consulting with a metallurgist or by using an annealing chart. Annealing charts provide recommended annealing temperatures for different metals and thicknesses.

5. What are the different methods used to control the cooling rate during annealing?

The cooling rate during annealing can be controlled by using different cooling methods, such as:

- Air Cooling: Cooling the metal in still air.

- Oil Quenching: Cooling the metal in oil.

- Water Quenching: Cooling the metal in water.

- Controlled Cooling: Cooling the metal in a controlled atmosphere, such as a furnace.

The cooling rate can also be controlled by varying the size and shape of the metal, as well as the temperature of the cooling medium.

6. How do you test the effectiveness of an annealing process?

The effectiveness of an annealing process can be tested by performing various tests on the annealed metal, such as:

- Hardness testing

- Tensile testing

- Impact testing

- Microstructure analysis

The results of these tests can be compared to the desired properties of the annealed metal to determine the effectiveness of the annealing process.

7. What are the common defects that can occur during annealing?

Common defects that can occur during annealing include:

- Overheating: Heating the metal to too high a temperature or for too long, which can cause grain growth and loss of strength.

- Underheating: Heating the metal to too low a temperature or for too short a time, which can result in incomplete recrystallization and insufficient softening.

- Non-uniform heating: Heating the metal unevenly, which can lead to variations in the microstructure and properties of the annealed metal.

- Excessive cooling rate: Cooling the metal too quickly after annealing, which can cause distortion and cracking.

8. How can you prevent defects from occurring during annealing?

To prevent defects from occurring during annealing, it is important to:

- Control the annealing temperature and time carefully

- Heat the metal uniformly

- Cool the metal at a controlled rate

- Use the appropriate annealing equipment

- Inspect the annealed metal for defects

9. What are the safety precautions that should be taken when annealing metals?

When annealing metals, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as heat-resistant gloves and clothing.

- Use a well-ventilated area.

- Keep the annealing furnace in good working order.

- Handle the annealed metal with care, as it may be hot and sharp.

- Follow all safety procedures and guidelines.

10. What are the recent advancements in annealing technology?

Recent advancements in annealing technology include:

- Vacuum annealing: Annealing metals in a vacuum environment to prevent oxidation and contamination.

- Controlled atmosphere annealing: Annealing metals in a controlled atmosphere to achieve specific properties.

- Laser annealing: Using lasers to heat and anneal metals locally.

- Microwave annealing: Using microwaves to heat and anneal metals.

These advancements have improved the efficiency and precision of the annealing process and have enabled the annealing of new materials and applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Annealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Annealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Annealers are responsible for heat treating metals to improve their properties. Their primary duties include:

1. Annealing

Annealing involves heating the metal to a specific temperature and holding it there for a controlled period, then cooling it slowly. This process makes the metal softer and more ductile

- Load and unload metal parts into annealing furnaces

- Monitor temperature and hold it within specified ranges

- Adjust cooling rates to achieve desired metallurgical properties

2. Equipment Maintenance

Ensuring the proper functioning of annealing furnaces and other equipment is crucial

- Perform regular inspections and maintenance tasks

- Identify and troubleshoot malfunctions

- Work with maintenance technicians to repair equipment

3. Quality Control

Metal Annealers play a vital role in ensuring the quality of the annealed parts

- Inspect annealed parts for defects, such as cracks or distortions

- Conduct hardness and other mechanical tests to verify properties

- Maintain records of annealing parameters and quality control results

4. Workplace Safety

Working in an industrial setting requires adherence to safety regulations

- Follow established safety protocols and wear appropriate protective gear

- Handle hazardous materials with care

- Maintain a clean and organized work area

Interview Tips

Preparing for an interview is crucial for success. Here are some tips to help candidates ace their Metal Annealer interview.

1. Research the Company and Position

Understanding the company’s culture, products, and industry is essential. Read their website, LinkedIn profile, and any relevant news articles.

- Tailor your answers to the specific requirements of the position.

- Highlight your skills and experience that align with the job responsibilities

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful responses. Practice answering aloud to improve your delivery and confidence.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples of your accomplishments and how they benefited your previous employer.

3. Highlight Your Technical Skills

Metal Annealing requires specialized technical knowledge. Showcase your expertise in:

- Annealing processes and principles

- Material properties and metallurgy

- Furnace operation and maintenance

4. Demonstrate Your Problem-Solving Abilities

Metal Annealers often face unexpected challenges. Highlight your ability to:

- Identify and diagnose equipment malfunctions

- Troubleshoot quality issues and suggest solutions

- Maintain productivity and efficiency even under pressure

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Annealer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!