Are you gearing up for a career in Metal Bench Patternmaker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Bench Patternmaker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

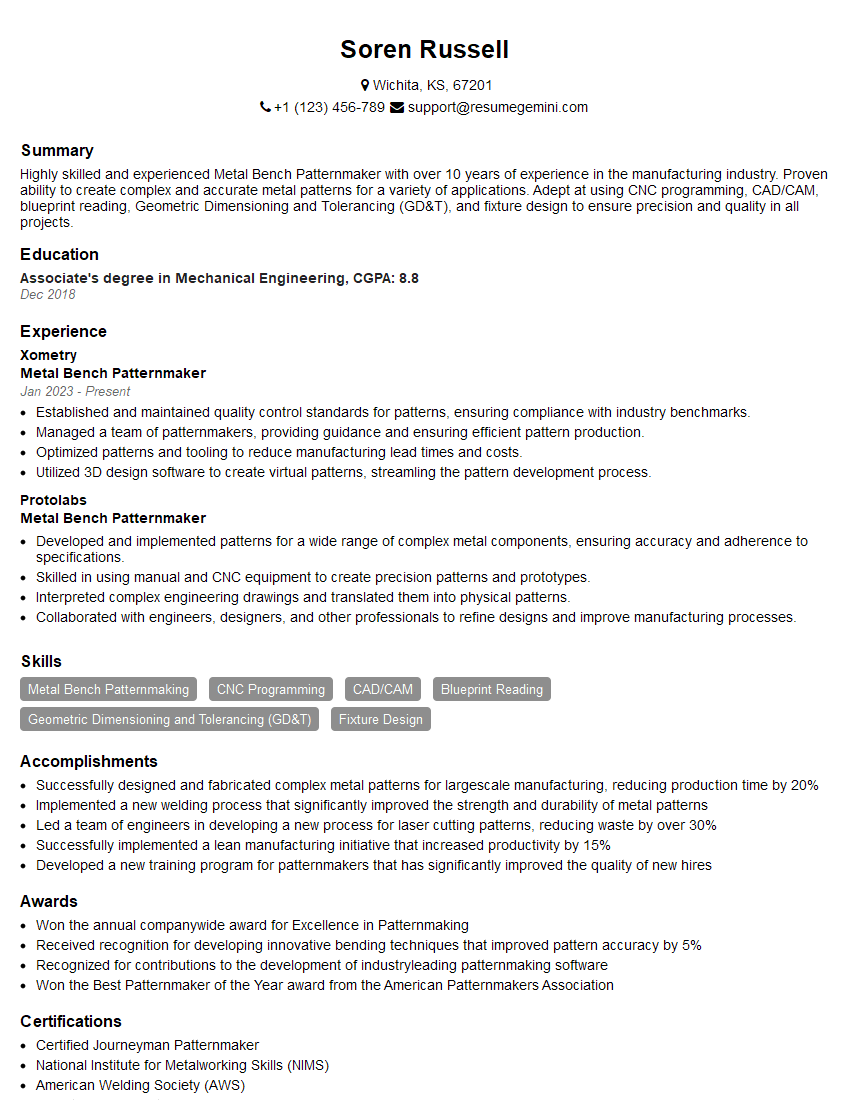

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Bench Patternmaker

1. What are the different types of patternmaking materials and their applications?

Patternmaking materials can be classified into two main types: wood and metal. Wood is the most common material used for patterns, as it is relatively inexpensive, easy to work with, and has good dimensional stability. Metal patterns are typically used for high-volume production runs, as they are more durable than wood patterns. Other materials that can be used for patterns include plastic, plaster, and wax.

- Wood: Wood is the most common patternmaking material, as it is relatively inexpensive, easy to work with, and has good dimensional stability.

- Metal: Metal patterns are typically used for high-volume production runs, as they are more durable than wood patterns.

- Plastic: Plastic patterns are often used for complex shapes, as they can be easily molded and formed.

- Plaster: Plaster patterns are often used for making molds, as they can be easily cast and have a high degree of accuracy.

- Wax: Wax patterns are often used for investment casting, as they can be easily melted and formed.

2. Explain the process of bench patternmaking.

Pattern design:

- The first step in bench patternmaking is to design the pattern. This involves creating a drawing or model of the part that is to be cast.

Pattern construction:

- Once the pattern has been designed, it is constructed using a variety of materials and techniques. The materials used will depend on the size, shape, and complexity of the part.

Pattern finishing:

- Once the pattern has been constructed, it is finished to ensure that it is accurate and durable. This may involve sanding, painting, or other finishing processes.

3. What are the different types of bench patternmaking tools and their uses?

There are a wide variety of bench patternmaking tools, each with its own specific purpose. Some of the most common tools include:

- Hand tools: Hand tools are used for a variety of tasks, such as cutting, shaping, and finishing patterns. Some of the most common hand tools include saws, chisels, gouges, and files.

- Power tools: Power tools can be used to speed up the patternmaking process. Some of the most common power tools include sanders, drills, and lathes.

- Measuring tools: Measuring tools are used to ensure that patterns are accurate. Some of the most common measuring tools include rulers, calipers, and micrometers.

4. What are the different types of patternmaking tolerances and how are they determined?

Patternmaking tolerances are the allowable deviations from the specified dimensions of a pattern. Tolerances are determined based on a number of factors, including the size, shape, and complexity of the part, as well as the casting process that will be used.

- Linear tolerances: Linear tolerances specify the allowable deviation from the specified length or width of a pattern.

- Angular tolerances: Angular tolerances specify the allowable deviation from the specified angle of a pattern.

- Form tolerances: Form tolerances specify the allowable deviation from the specified shape of a pattern.

5. What are the different types of patternmaking defects and how can they be prevented?

Patternmaking defects can occur for a variety of reasons, including improper design, construction, or finishing. Some of the most common patternmaking defects include:

- Dimensional errors: Dimensional errors occur when the pattern does not conform to the specified dimensions.

- Surface defects: Surface defects occur when the surface of the pattern is not smooth or uniform.

- Core shift: Core shift occurs when the core is not properly aligned with the pattern.

Patternmaking defects can be prevented by following proper design, construction, and finishing techniques. It is also important to use high-quality materials and to inspect patterns regularly for defects.

6. What are the different types of patternmaking allowances and how are they determined?

Patternmaking allowances are the extra dimensions that are added to a pattern to compensate for shrinkage and other factors that can affect the casting process. Allowances are determined based on a number of factors, including the size, shape, and complexity of the part, as well as the casting process that will be used.

- Shrinkage allowance: Shrinkage allowance is the extra dimension that is added to a pattern to compensate for the shrinkage that occurs when the metal solidifies.

- Draft allowance: Draft allowance is the extra dimension that is added to a pattern to make it easier to remove the pattern from the mold.

- Machining allowance: Machining allowance is the extra dimension that is added to a pattern to allow for machining operations that will be performed on the casting.

7. What are the different types of patternmaking gates and risers and how are they used?

Patternmaking gates and risers are used to control the flow of molten metal into and out of the mold. Gates are openings in the pattern that allow molten metal to enter the mold. Risers are openings in the pattern that allow air and gases to escape from the mold.

- Gates: Gates are typically located at the bottom of the mold, and they are designed to allow molten metal to enter the mold in a controlled manner.

- Risers: Risers are typically located at the top of the mold, and they are designed to allow air and gases to escape from the mold.

8. What are the different types of patternmaking molding materials and their applications?

Patternmaking molding materials are the materials that are used to create the mold into which the molten metal will be poured. Molding materials can be classified into two main types: sand and metal.

- Sand: Sand is the most common patternmaking molding material. It is relatively inexpensive, easy to work with, and has good dimensional stability.

- Metal: Metal molding materials are typically used for high-volume production runs, as they are more durable than sand molding materials.

9. What are the different types of patternmaking molding processes and their applications?

Patternmaking molding processes can be classified into two main types: sand casting and metal casting.

- Sand casting: Sand casting is the most common patternmaking molding process. It is relatively inexpensive and can be used to produce a wide variety of castings.

- Metal casting: Metal casting is a more specialized patternmaking molding process that is used to produce high-quality castings.

10. What are the different types of patternmaking finishing processes and their applications?

Patternmaking finishing processes are the processes that are used to give patterns a smooth, uniform surface. Finishing processes can be classified into two main types: hand finishing and machine finishing.

- Hand finishing: Hand finishing is the most common patternmaking finishing process. It involves using hand tools to remove burrs, sharp edges, and other imperfections from the pattern.

- Machine finishing: Machine finishing is a more specialized patternmaking finishing process that is used to produce high-quality patterns.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Bench Patternmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Bench Patternmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Bench Patternmakers play a crucial role in metalworking by constructing and repairing patterns used in the casting process. Their key responsibilities include:

1. Pattern Construction and Repair

Plan and construct wooden and metal patterns based on blueprints, sketches, or models.

- Select and use appropriate materials and tools for pattern construction.

- Ensure patterns meet required dimensions and tolerances.

2. Pattern Modification

Modify existing patterns to accommodate design changes or casting defects.

- Analyze patterns and identify areas needing modification.

- Use specialized tools and techniques to make modifications.

3. Material Selection and Machining

Select and machine materials suitable for the intended casting process.

- Understand properties of different metals and alloys.

- Operate CNC machines and other equipment to shape and finish metal parts.

4. Quality Control

Inspect patterns and castings for defects and ensure they meet specifications.

- Use measuring instruments and gauges to verify dimensions and tolerances.

- Report any deviations or defects to supervisors or engineers.

Interview Tips

Preparing for a Metal Bench Patternmaker interview can increase your chances of making a positive impression and landing the job. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and services.

- Visit the company website and social media pages.

- Research industry trends and news.

2. Practice Common Interview Questions

Prepare for questions about your technical skills, experience, and why you’re interested in the position.

- Example Outline:

Tell me about your experience constructing wooden and metal patterns.

- Highlight your skills in selecting and using materials, following blueprints, and meeting tolerances.

- Provide specific examples of projects you’ve worked on.

3. Showcase Your Knowledge of the Casting Process

Explain your understanding of the various casting methods and the role of patterns in the process.

- Example Outline:

Describe the differences between sand casting, investment casting, and die casting.

- Explain the advantages and disadvantages of each method.

- Discuss how patterns are used in each process.

4. Emphasize Your Problem-Solving Abilities

Share examples of how you’ve solved problems related to pattern construction or modification.

- Example Outline:

Tell me about a time when you had to modify a pattern due to a design change.

- Describe the problem you encountered.

- Explain the steps you took to modify the pattern.

- Discuss the outcome and how you ensured the modified pattern met specifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Bench Patternmaker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!