Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Bonding Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Bonding Assembler so you can tailor your answers to impress potential employers.

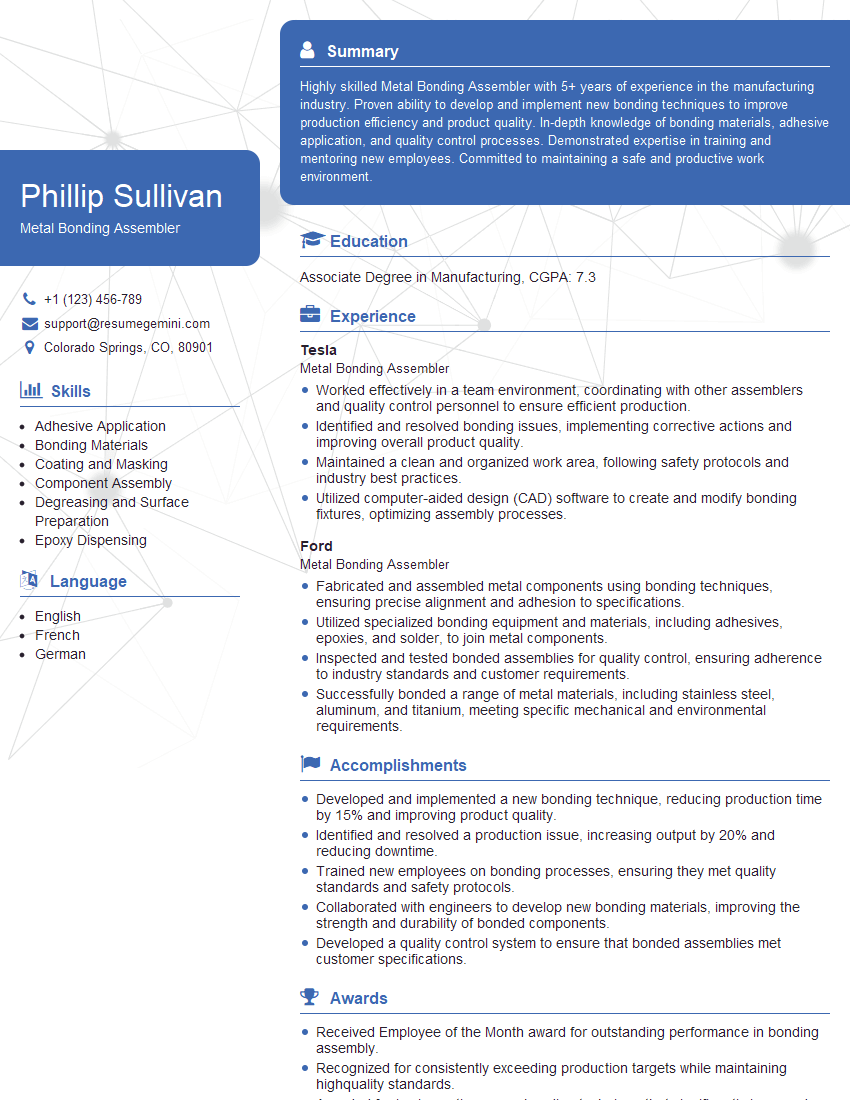

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Bonding Assembler

1. What are the different types of adhesives used in metal bonding?

In metal bonding, various adhesives are used, each with unique properties and applications. Here are some common types:

- Epoxy adhesives: Known for their high strength and durability, epoxy adhesives create strong bonds between dissimilar materials.

- Acrylic adhesives: Offering excellent clarity and UV resistance, acrylic adhesives are widely used in bonding transparent materials.

- Cyanoacrylate adhesives: Popularly known as super glue, cyanoacrylate adhesives provide rapid bonding and are suitable for small-scale applications.

- Anaerobic adhesives: Designed to cure in the absence of air, anaerobic adhesives are ideal for bonding metal components with close-fitting joints.

2. Describe the process of surface preparation for metal bonding.

Cleaning and Degreasing

- Thoroughly clean the metal surfaces to remove dirt, oil, and other contaminants using solvents or detergents.

- Degrease the surfaces with solvents to ensure optimal adhesive bonding.

Mechanical Abrasion

- Roughen the metal surfaces by sanding, grinding, or grit blasting to increase surface area and improve adhesive adhesion.

- Remove any debris or dust created during abrasion.

Chemical Treatment

- Apply chemical treatments, such as acid etching or anodizing, to further enhance surface reactivity and promote bonding.

- Follow the manufacturer’s instructions and safety precautions carefully.

3. What factors affect the strength of a metal-to-metal bond?

The strength of a metal-to-metal bond depends on several factors:

- Surface preparation: Proper surface cleaning, abrasion, and treatment ensure optimal adhesion.

- Adhesive selection: Choosing the right adhesive for the specific materials and application is crucial.

- Bonding conditions: Factors such as temperature, pressure, and curing time influence bond strength.

- Joint design: The geometry and thickness of the joint affect stress distribution and bond strength.

- Environmental factors: Exposure to moisture, temperature fluctuations, and chemicals can impact bond durability.

4. Explain the difference between adhesive bonding and mechanical fastening.

Adhesive Bonding

Involves using adhesives to join metal components, creating a continuous bond that distributes stress evenly.

- Advantages: Strong bonds, lightweight, corrosion resistance, and design flexibility.

- Disadvantages: Requires careful surface preparation, curing time, and potential sensitivity to environmental factors.

Mechanical Fastening

Employs mechanical fasteners, such as bolts, screws, or rivets, to hold metal components together.

- Advantages: Quick and straightforward, provides strong connections, and can be disassembled.

- Disadvantages: Can create stress concentrations, add weight, and compromise corrosion resistance.

5. What are the key considerations when selecting an adhesive for metal bonding?

Choosing the appropriate adhesive for metal bonding involves considering several factors:

- Strength and durability: Ensure the adhesive can withstand the expected loads and environmental conditions.

- Adhesion properties: Verify the adhesive’s ability to bond effectively to the specific metal surfaces.

- Application method: Consider the ease of application, curing time, and any special equipment required.

- Environmental resistance: Determine the adhesive’s tolerance to moisture, temperature, and chemicals.

- Cost and availability: Evaluate the cost and availability of the adhesive in relation to the project requirements.

6. What quality control measures are important in metal bonding?

- Surface preparation verification: Inspect surfaces for proper cleaning, abrasion, and treatment.

- Adhesive application control: Ensure accurate mixing, dispensing, and curing of the adhesive.

- Bond strength testing: Conduct destructive or non-destructive testing to assess the strength and integrity of the bonds.

- Visual inspection: Examine the bonded components for any defects, gaps, or contamination.

- Environmental testing: Expose bonded samples to anticipated environmental conditions to evaluate durability.

7. Describe your experience in using different types of metal bonding adhesives.

In my previous role as a Metal Bonding Assembler, I gained extensive experience in using various types of metal bonding adhesives. I have successfully bonded metals such as aluminum, steel, and titanium using:

- Epoxy adhesives for high-strength structural bonding in applications requiring durability and resistance to harsh environments.

- Acrylic adhesives for bonding transparent materials, such as acrylics and polycarbonate, providing excellent clarity and UV resistance.

- Anaerobic adhesives for bonding metal components with close-fitting joints, offering fast curing and resistance to vibration and shock.

8. How do you ensure the accuracy and precision of your metal bonding work?

Accuracy and precision are paramount in metal bonding. I employ several techniques to achieve this:

- Precise surface preparation: I carefully follow prescribed surface preparation protocols to ensure proper adhesion.

- Controlled adhesive application: I use precision tools and techniques to ensure accurate dispensing and placement of the adhesive.

- Alignment and fixturing: I utilize jigs, fixtures, and alignment tools to ensure precise positioning of components during bonding.

- Curing control: I strictly adhere to recommended curing times and temperatures to ensure optimal bond strength and durability.

- Quality checks: I perform regular inspections and testing to verify the accuracy and integrity of my work.

9. What safety precautions do you take when working with metal bonding adhesives?

Working with metal bonding adhesives requires strict adherence to safety precautions:

- Personal protective equipment: I always wear gloves, safety glasses, and a respirator when handling adhesives and solvents.

- Ventilation: I ensure adequate ventilation in the work area to prevent exposure to harmful fumes.

- Hazardous waste disposal: I properly dispose of used adhesives, solvents, and other hazardous materials according to regulations.

- Training and certification: I regularly attend training and maintain certifications related to the safe handling and use of metal bonding adhesives.

10. How do you stay up-to-date with the latest advancements in metal bonding technology?

To stay abreast of the latest advancements in metal bonding technology, I engage in the following activities:

- Industry publications and journals: I subscribe to relevant industry publications and journals to access cutting-edge research and best practices.

- Conferences and training: I attend industry conferences and training programs to learn from experts and stay informed about new technologies and techniques.

- Online resources: I utilize reputable online resources, such as technical forums and manufacturer websites, to gather information and connect with other professionals.

- Collaboration and networking: I actively participate in industry organizations and collaborate with colleagues to share knowledge and stay informed about emerging trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Bonding Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Bonding Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Bonding Assemblers play a crucial role in manufacturing processes by assembling components using metal bonding techniques. Their responsibilities encompass a wide range of tasks that require precision, attention to detail, and a comprehensive understanding of bonding procedures.

1. Adhere to Bonding Specifications

Meticulously follow established bonding specifications and guidelines to ensure precise and consistent assembly of components.

- Review and interpret technical drawings, blueprints, and assembly instructions.

- Select appropriate adhesives and bonding materials based on specific requirements.

2. Prepare Components for Bonding

Dili gently prepare component surfaces for bonding by removing contaminants, ensuring proper alignment, and applying adhesives.

- Clean and degrease surfaces to remove dirt, oil, and other impurities.

- Align components accurately using jigs, fixtures, or specialized equipment.

- Apply adhesives evenly and precisely, ensuring proper coverage and bond strength.

3. Perform Bonding Operations

Skillfully execute bonding operations using various techniques, including:

- Applying heat or pressure to cure adhesives and create strong bonds.

- Utilizing clamps, presses, or other tools to maintain alignment and pressure during bonding.

- Inspecting bonded joints for proper adhesion and adherence to specifications.

4. Maintain Equipment and Work Area

Uphold a clean and organized work area to ensure efficiency and safety.

- Clean and maintain bonding equipment, including adhesives, applicators, and curing devices.

- Dispose of hazardous materials and waste in accordance with environmental regulations.

- Maintain a well-stocked inventory of adhesives, bonding materials, and other supplies.

Interview Tips

To ace the interview for a Metal Bonding Assembler position, consider the following preparation tips and interview hacks:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s background, products or services, and industry trends.

- Visit the company website, LinkedIn page, and news articles to gather information.

- Identify the company’s mission, values, and key differentiators.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in metal bonding techniques, equipment handling, and quality control procedures.

- Quantify your experience by providing specific examples of projects or accomplishments.

- Discuss your understanding of different bonding adhesives and their applications.

3. Prepare for Technical Questions

Anticipate technical questions related to metal bonding processes, materials, and quality standards.

- Review basic principles of adhesion, bonding strength, and surface preparation.

- Be familiar with industry-specific standards and regulations, such as ISO 9001.

4. Showcase Your Attention to Detail

Metal bonding requires meticulous attention to detail. Highlight your ability to follow instructions precisely and maintain a clean and organized work area.

- Provide examples of your commitment to quality and accuracy in previous roles.

- Explain how you handle potential errors or deviations from specifications.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Bonding Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!