Feeling lost in a sea of interview questions? Landed that dream interview for Metal Buffer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Buffer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

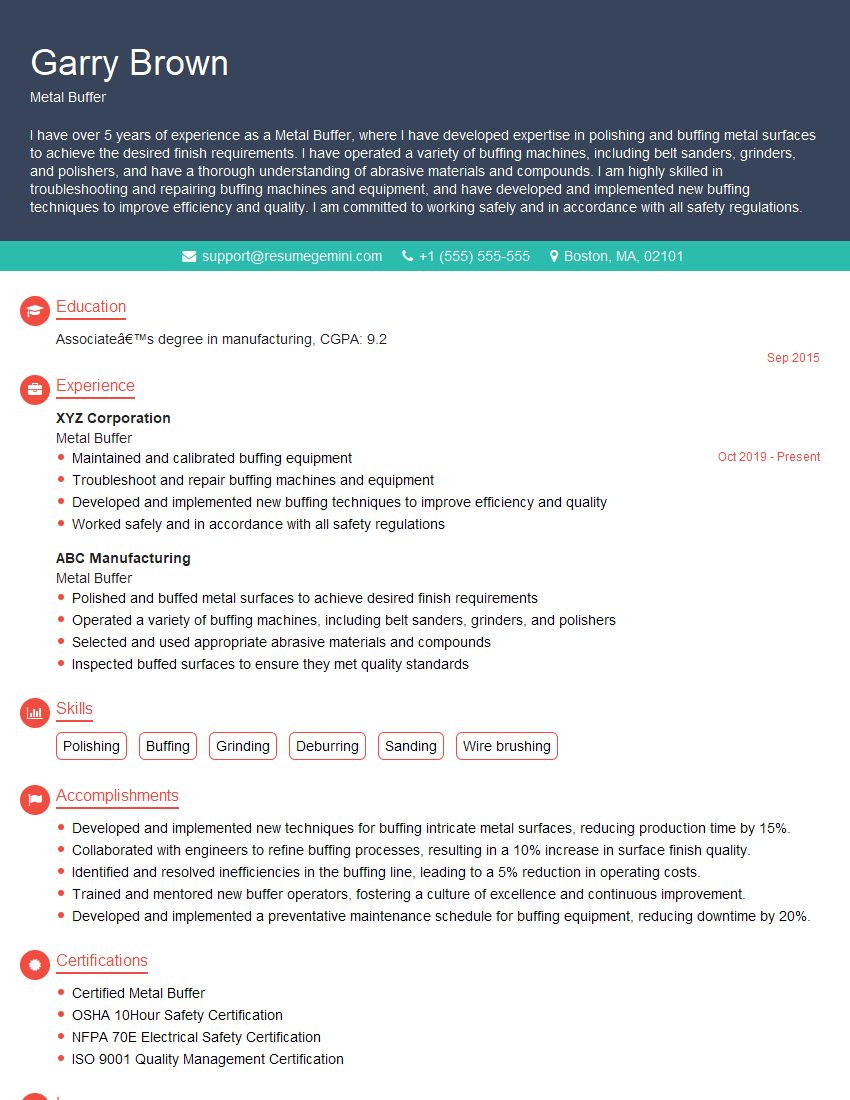

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Buffer

1. Explain the metal buffing process and the different types of buffing wheels used?

The metal buffing process involves removing imperfections, blemishes, and burrs from metal surfaces using abrasive compounds and rotating buffing wheels. Different types of buffing wheels are used depending on the desired finish, including:

- Sisal wheels: Coarse fibers for heavy-duty cutting and removing large imperfections.

- Cotton wheels: Medium fibers for general-purpose buffing and polishing.

- Felt wheels: Soft fibers for fine finishing and achieving a high shine.

- Buffing wheels with abrasive compounds: Impregnated with abrasives (e.g., aluminum oxide, tripoli) for specific finishing requirements.

2. What are the safety precautions to be taken while operating a metal buffing machine?

Protective Gear:

- Wear appropriate personal protective equipment (PPE) such as goggles, gloves, and a dust mask.

Machine Operation:

- Ensure the machine is properly grounded and in good working condition.

- Inspect buffing wheels for damage before use and replace if necessary.

- Mount the workpiece securely to prevent it from flying off the wheel.

- Maintain a safe distance from the wheel while buffing.

- Never reach across the wheel while it is rotating.

Workplace Environment:

- Ventilate the area adequately to remove dust and fumes.

- Keep the work area clean and free from debris.

3. How do you determine the appropriate speed and pressure for buffing different metals?

The appropriate speed and pressure for buffing different metals vary depending on the metal’s hardness and the desired finish. Here are some general guidelines:

- Hard metals (e.g., steel, stainless steel): Use higher speeds (2,000-3,000 RPM) and medium pressure to remove imperfections.

- Soft metals (e.g., aluminum, brass): Use lower speeds (1,000-2,000 RPM) and lighter pressure to avoid damaging the surface.

- Polishing: Use ultra-high speeds (3,000+ RPM) and minimal pressure to achieve a mirror-like finish.

4. How do you troubleshoot common issues encountered in metal buffing, such as overheating or uneven finishing?

Common issues in metal buffing and their troubleshooting steps include:

- Overheating: Check if the speed or pressure is too high, or if the workpiece is not properly mounted. Adjust the settings or improve the mounting.

- Uneven finishing: Ensure the workpiece is moved evenly across the buffing wheel. Use a fixture or jig to maintain consistency.

- Buffing streaks: Clean the buffing wheel to remove embedded particles or use a finer abrasive compound.

- Poor adhesion of abrasive compounds: Check if the buffing wheel is clean and dry. Use an adhesive promoter or switch to a different compound.

5. Describe your experience in maintaining and calibrating metal buffing machines?

In my previous role, I was responsible for the maintenance and calibration of various metal buffing machines. My tasks included:

- Regularly inspecting machines for wear and tear, and performing preventive maintenance.

- Calibrating speedometers and pressure gauges to ensure accurate operation.

- Troubleshooting and repairing any machine malfunctions, such as motor failures or wheel imbalances.

- Ensuring that all safety features were functioning properly.

6. How do you select the most appropriate abrasive compounds for different metal buffing applications?

The selection of abrasive compounds for metal buffing depends on the metal type and the desired finish:

- Coarse abrasives (e.g., aluminum oxide, silicon carbide): For heavy-duty cutting and removing imperfections.

- Medium abrasives (e.g., pumice, tripoli): For general-purpose buffing and polishing.

- Fine abrasives (e.g., rouge, diamond paste): For achieving high-quality finishes and mirror-like polishing.

7. Explain the importance of surface preparation before metal buffing?

Proper surface preparation is crucial before metal buffing to ensure effective removal of imperfections and achieve the desired finish. It involves:

- Cleaning: Removing dirt, grease, and other contaminants that can interfere with buffing.

- Degreasing: Using solvents or degreasers to remove oils and lubricants.

- Abrasive blasting: Using abrasive media to remove heavy rust, scale, or burrs.

- Mechanical grinding: Using grinding wheels or belts to smooth rough surfaces.

8. How do you ensure the quality and consistency of metal buffing processes?

To ensure quality and consistency in metal buffing processes, I follow these practices:

- Use standardized procedures: Establish clear guidelines for each metal buffing operation.

- Regularly calibrate equipment: Ensure that buffing machines, speedometers, and pressure gauges are accurate.

- Inspect workpieces throughout the process: Check for surface defects, imperfections, and proper finish.

- Document process parameters: Record key variables such as speed, pressure, and abrasive compounds used.

- Implement quality control measures: Conduct regular inspections and audits to verify the quality of the finished products.

9. How do you handle buffing of complex-shaped metal objects?

Buffing complex-shaped metal objects requires special techniques and equipment:

- Use specialized buffing tools: Utilize contour buffs, bobbing wheels, and polishing brushes to access intricate areas.

- Employ fixtures and jigs: Securely hold the workpiece in place for precise and consistent buffing.

- Adjust machine settings: Modify speed, pressure, and abrasive compounds to accommodate the object’s shape.

- Manually guide the workpiece: Carefully move the object across the buffing wheel to achieve a uniform finish.

10. Have you worked with any specific surface finishes, such as mirror finishing or satin finishing?

Yes, in my previous role, I had extensive experience in achieving various surface finishes, including:

- Mirror finishing: Performed multiple buffing passes with fine abrasives and polishing compounds to create a highly reflective surface.

- Satin finishing: Controlled the buffing process and used specific abrasive compounds to create a smooth and evenly textured surface with a subtle sheen.

- Brushing finishing: Utilized rotating wire brushes to create a brushed or textured effect on metal surfaces.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Buffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Buffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Buffer is responsible for performing various tasks related to the finishing and preparation of metal surfaces. Their primary objective is to ensure that metal components meet the required specifications for smoothness, finish, and overall quality.

1. Surface Preparation

Prior to buffing, Metal Buffers prepare metal surfaces by removing any existing imperfections, such as scratches, dents, or corrosion. This may involve processes like sanding, grinding, or polishing.

2. Buffing and Polishing

Using specialized machinery, Metal Buffers buff and polish metal surfaces to achieve the desired finish. Buffing involves removing surface imperfections, while polishing creates a smooth, reflective surface.

3. Material Handling

Metal Buffers are responsible for handling and maneuvering heavy metal components, ensuring they are securely positioned for buffing and polishing.

4. Quality Control

Metal Buffers must inspect and assess the quality of their work, adhering to strict quality standards. They verify surface finish, smoothness, and dimensional accuracy.

5. Equipment Maintenance

To ensure optimal performance, Metal Buffers are responsible for maintaining and cleaning buffing and polishing equipment, replacing abrasives, and performing minor repairs.

Interview Tips

Preparing for a Metal Buffer interview requires a combination of technical knowledge and effective presentation skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and the specific job requirements. This will enable you to tailor your answers to the interviewer’s expectations.

2. Highlight Relevant Experience

Emphasize your previous experience in metalworking, surface finishing, or related industries. Quantify your accomplishments using specific examples and metrics.

3. Showcase Technical Knowledge

Demonstrate your understanding of metal buffing and polishing techniques, equipment, and materials. Exhibit proficiency in quality control processes and industry standards.

4. Prepare for Behavioral Questions

Using the STAR method (Situation, Task, Action, Result), prepare examples that illustrate your problem-solving skills, attention to detail, and ability to work in a fast-paced environment.

5. Ask Thoughtful Questions

At the end of the interview, ask insightful questions that show your interest in the company, the role, and the industry. This will leave a positive impression and demonstrate your engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Buffer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!