Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Caster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

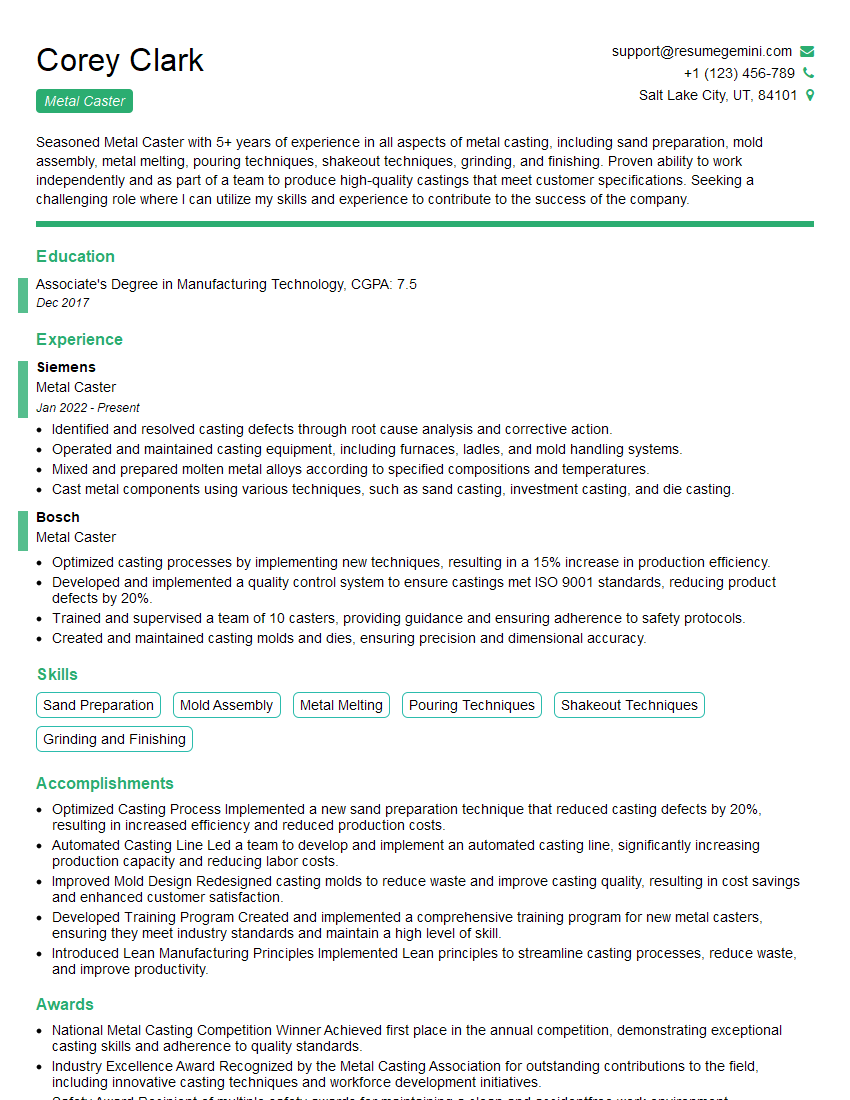

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Caster

1. Describe the steps involved in the metal casting process?

The metal casting process typically involves the following steps:

- Patternmaking: Creating a pattern or mold of the desired object.

- Molding: Preparing the mold using various materials like sand, plaster, or metal.

- Melting: Heating the metal to its melting point in a furnace or crucible.

- Pouring: Carefully pouring the molten metal into the mold.

- Solidification: Allowing the metal to cool and solidify within the mold.

- Shakeout: Removing the solidified casting from the mold.

- Finishing: Trimming, grinding, and polishing the casting to achieve the desired surface finish.

2. Explain the different types of metal casting processes?

Sand Casting

- Uses sand as the mold material.

- Suitable for large and complex castings.

Investment Casting

- Involves creating a ceramic mold using a wax pattern.

- Produces high-precision castings with intricate details.

Die Casting

- Forces molten metal into a metal die under high pressure.

- Suitable for mass production of small and medium-sized castings.

Centrifugal Casting

- Spins the mold during pouring to distribute the metal evenly.

- Produces castings with improved strength and density.

3. What are the key factors to consider when selecting a metal casting process?

- Casting size and complexity: Different processes are suitable for different sizes and shapes.

- Material properties: The melting point and fluidity of the metal affect the process choice.

- Production volume: Some processes are more efficient for mass production.

- Cost: The cost of equipment, materials, and labor varies between processes.

- Quality requirements: The desired surface finish and dimensional accuracy influence the process selection.

4. How do you ensure the quality of metal castings?

- Pattern accuracy: Verifying the dimensions and tolerances of the pattern.

- Mold preparation: Properly compacting and ventilating the mold to avoid defects.

- Metal preparation: Ensuring the metal is clean and free from impurities.

- Pouring technique: Controlling the pouring temperature and speed to minimize turbulence and air entrapment.

- Cooling rate: Monitoring the cooling process to prevent cracking or distortion.

- Post-processing: Inspecting, cleaning, and finishing the casting to meet specifications.

5. What are the common defects in metal castings and how do you prevent them?

Porosity

- Causes: Air entrapment, gas evolution, or shrinkage cavities.

- Prevention: Degassing metal, using proper gating and risering, and controlling cooling rate.

Cold Shut

- Causes: Incomplete filling of the mold during pouring.

- Prevention: Ensuring sufficient metal volume and proper pouring technique.

Hot Tear

- Causes: Stresses induced during cooling due to uneven shrinkage.

- Prevention: Controlling cooling rate, using chills and risers, and avoiding sharp corners in the casting.

6. Describe the gating and risering system in metal casting?

- Gating: A system of channels that guide the molten metal into the mold cavity.

- Risers: Reservoirs of molten metal that compensate for shrinkage during solidification and prevent shrinkage cavities.

- Proper gating and risering ensure adequate metal flow, reduce defects, and maintain casting integrity.

7. What are the safety precautions that should be observed in a metal casting foundry?

- Wear appropriate protective gear (e.g., gloves, safety glasses, apron).

- Handle molten metal with extreme care.

- Ensure proper ventilation to prevent gas inhalation.

- Maintain a clean and organized work area.

- Follow established safety procedures and protocols.

8. How do you stay updated on the latest advancements and best practices in metal casting?

- Attend industry conferences and exhibitions.

- Read technical journals and publications.

- Engage in online forums and discussions.

- Participate in professional development programs.

- Collaborate with colleagues and experts in the field.

9. Describe your experience with different types of casting materials?

I have experience working with various casting materials, including:

- Aluminum

- Steel

- Bronze

- Cast iron

- Magnesium

I understand their unique properties, such as melting point, fluidity, and strength, and can select the appropriate material based on the casting requirements.

10. How do you handle and troubleshoot casting defects?

- Identify the defect type: Visually inspect the casting and compare it to quality standards.

- Determine the root cause: Analyze the casting process, mold design, and material properties to identify potential issues.

- Implement corrective measures: Modify the process parameters, adjust the mold design, or change the casting material to eliminate the defect.

- Validate the solution: Recast the part and inspect it to ensure the defect has been resolved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Casters are manufacturing professionals who specialize in shaping molten metal into usable products. Their duties encompass the entire casting process, from preparing molds to pouring molten metal and post-casting treatments.

1. Mold Preparation

Prepare and maintain molds and cores used in the casting process.

- Assemble and repair molds according to design specifications.

- Inspect molds for accuracy and defects.

- Apply mold coatings and release agents to facilitate casting.

2. Metal Handling and Pouring

Operate furnaces to melt and refine molten metal.

- Calculate and weigh appropriate amounts of metal alloys.

- Pour molten metal into molds with precision and accuracy.

- Monitor and adjust pouring temperature and flow to ensure optimal casting.

3. Casting Finishing and Inspection

Remove castings from molds and perform post-casting treatments.

- Clean castings to remove excess material and defects.

- Heat-treat castings to improve their properties.

- Inspect castings for adherence to specifications and quality standards.

4. Equipment Maintenance and Calibration

Maintain and calibrate casting equipment to ensure accuracy and efficiency.

- Clean and lubricate machines.

- Calibrate sensors and gauges.

- Troubleshoot and resolve equipment malfunctions.

Interview Tips

A successful interview for a Metal Caster position requires preparation and a thorough understanding of the job’s responsibilities. Here are some tips to help you ace the interview:

1. Research the Company and Role

Take the time to learn about the company’s history, products, and industry standing. Read job descriptions and research the specific requirements for the Metal Caster position.

- Tailor your answers to the company’s specific needs and the role’s responsibilities.

- Example: “Based on my research, I noticed that your company specializes in high-volume metal casting. I am particularly proficient in optimizing furnace efficiency for mass production, which aligns with your requirements.”

2. Highlight Relevant Skills and Experience

Emphasize your expertise in key casting processes, such as mold preparation, metal handling, and casting finishing. Quantify your achievements whenever possible.

- Example: “In my previous role, I implemented a new mold coating technique that reduced casting defects by 20%, significantly improving production yields.”

- Include any certifications or training in your field, such as the American Foundry Society’s Certified Foundryman program.

3. Demonstrate Safety Consciousness

Metal casting involves working with hazardous materials and equipment. Highlight your commitment to maintaining a safe work environment.

- Example: “I am highly proficient in following industry-standard safety protocols, including proper handling of molten metal, wearing appropriate PPE, and conducting regular equipment safety checks.”

- Discuss your experience in hazard identification and risk assessment.

4. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your engagement and interest in the position and the company.

- Inquire about the company’s growth plans and how the Metal Caster role fits into those plans.

- Ask about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Caster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!