Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Ceiling Hanger interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Ceiling Hanger so you can tailor your answers to impress potential employers.

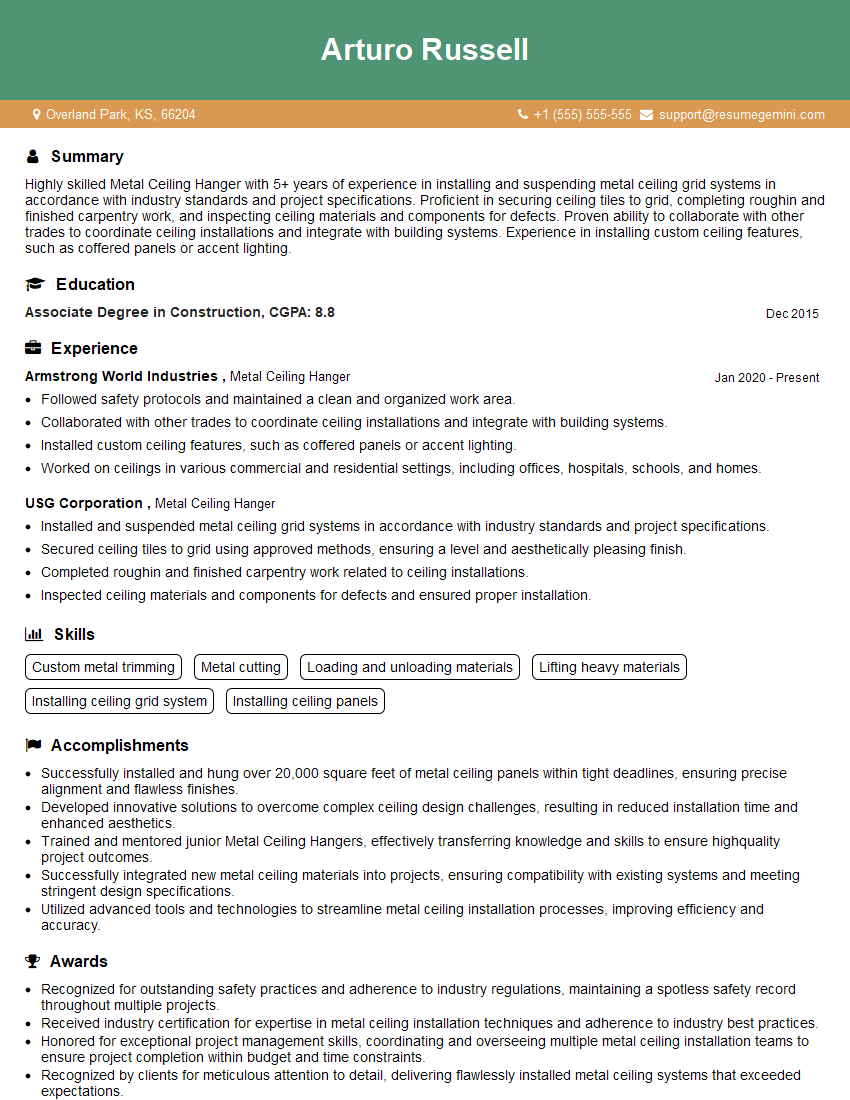

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Ceiling Hanger

1. What are the different types of metal ceiling systems available and their applications?

- Exposed Grid System: Suitable for areas requiring easy access to ceiling components, like plenum spaces or mechanical systems.

- Concealed Grid System: Provides a clean, finished appearance with grid lines hidden by ceiling tiles, ideal for commercial and residential applications.

- Linear System: Characterized by long, narrow panels that create a modern and sleek aesthetic, often used in large open spaces.

- Coffered System: Features recessed panels that create a unique and decorative design, suitable for high-end commercial or institutional spaces.

- Plank System: Comprises interlocking panels that create a seamless look, commonly used in commercial offices or public areas.

2. Describe the proper installation procedure for a metal ceiling suspension system.

Suspension System Installation

- Layout and mark the suspension grid layout according to the ceiling plan.

- Install wall moldings or perimeter channels to support the grid at the walls.

- Suspend main runners from the ceiling structure using hangers and wire.

- Interconnect the main runners using cross tees to create the grid system.

Panel Installation

- Place tiles into the grid system, starting from the center.

- Ensure tiles are aligned properly and securely fastened.

- Trim excess tile around the perimeter if necessary.

3. How do you determine the appropriate spacing and gauge of metal ceiling hangers based on ceiling load?

- Calculate the weight of the metal ceiling system, including panels, suspension system, and lighting fixtures.

- Consult manufacturer’s specifications to determine the load capacity of the hangers.

- Determine the required spacing based on the load capacity and the weight of the system.

- Select hangers with adequate gauge to support the load without bending or deformation.

4. What are the common causes of sagging or deflection in metal ceilings and how can they be prevented?

- Insufficient Hanger Spacing: Hangers should be spaced according to manufacturer’s specifications to prevent excessive deflection.

- Overload: Ceiling systems should not be overloaded with additional weight, like bulky light fixtures or equipment.

- Improper Hanger Attachment: Hangers must be securely fastened to the ceiling structure to prevent them from pulling out.

- Damaged or Bent Components: Inspect suspension components for any damage or bending, which can weaken the system.

5. How do you ensure a level and plumb metal ceiling installation?

- Establish Reference Points: Use a laser level to create reference points around the perimeter of the ceiling.

- Align Hangers: Adjust hangers as needed to align with the reference points and ensure a level grid system.

- Measure and Adjust: Check the level and plumb of the grid and adjust hangers or support wires as necessary.

- Use Leveling Devices: Utilize leveling screws or clips to adjust the height and level of tiles if needed.

6. Describe the techniques for cutting and shaping metal ceiling tiles to accommodate obstacles or irregular spaces.

- Cutting: Use metal shears or a tin snips to cut straight lines.

- Scoring and Bending: Score and bend metal tiles to create curves or angles using a utility knife or bending brake.

- Notching: Cut notches into tiles using a nibbler or a hacksaw to fit around obstacles.

- Fabricating Custom Shapes: Complex shapes can be fabricated by cutting and welding individual pieces of metal.

7. What are the best practices for inspecting and maintaining metal ceilings to ensure their longevity and appearance?

- Regular Cleaning: Wipe down ceilings with a soft cloth and mild cleaning solution to remove dust and debris.

- Inspection: Check for signs of damage, corrosion, or loose components on a regular basis.

- Tile Replacement: Replace damaged or discolored tiles as needed to maintain a uniform appearance.

- Repainting: Repaint the ceiling as necessary to prevent rust or fading.

- Professional Cleaning: Hire a professional to deep clean the ceiling periodically to remove stubborn stains or dirt.

8. How do you troubleshoot common problems encountered during metal ceiling installation, such as gaps between tiles or visible seams?

- Gaps Between Tiles: Check the grid spacing and hanger alignment to ensure they are correct. Adjust tiles as needed or replace gaps with filler strips.

- Visible Seams: Inspect the tile edges for burrs or imperfections that may prevent them from locking securely. Use a soft brush to smooth out any sharp edges.

- Loose Tiles: Check if the tiles are fully engaged in the grid system. Re-install or replace any loose tiles as needed.

- Warped Tiles: If tiles are warped, remove and flatten them using a weight or bending brake.

9. What are the safety precautions that need to be followed when installing or repairing metal ceilings?

- Proper PPE: Wear gloves, safety glasses, and a hard hat when handling metal components.

- Electrical Safety: Ensure all electrical connections are secure and insulated.

- Height Safety: Use appropriate ladders or scaffolding to access high ceilings.

- Sharp Edges: Be aware of sharp edges on metal components and wear protective gear to avoid cuts.

- Lifting Safety: Use proper lifting techniques when handling heavy materials.

10. Describe the different materials and finishes used in metal ceiling systems and their advantages and disadvantages.

Materials

- Aluminum: Lightweight, corrosion-resistant, available in various finishes.

- Steel: Strong, durable, can be painted or coated.

- Stainless Steel: Highly corrosion-resistant, ideal for harsh environments.

- Copper: Corrosion-resistant, develops a natural patina over time.

Finishes

- Painted: Wide range of colors and textures.

- Powder Coated: Durable, scratch-resistant finish.

- Anodized: Corrosion-resistant, creates a unique metallic sheen.

- Perforated: Allows for sound absorption and airflow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Ceiling Hanger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Ceiling Hanger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Ceiling Hanger is responsible for installing and repairing metal ceilings in commercial and residential buildings, ensuring the accuracy and quality of the installation. Their primary duties include:

1. Installation

Hang and secure metal ceiling tiles and panels to structural supports using hand tools and power equipment.

2. Repair and Maintenance

Inspect metal ceilings for damage or defects, and make necessary repairs or replacements to maintain their integrity.

3. Planning and Preparation

Read blueprints and specifications to understand the project requirements and plan the installation process accordingly.

4. Safety and Compliance

Follow safety regulations and wear appropriate protective gear while working at heights and handling heavy materials.

Interview Tips

Preparing for an interview for a Metal Ceiling Hanger position can increase your chances of success. Consider the following tips:

1. Research the Company and Position

Learn about the company’s values, services, and the specific requirements of the Metal Ceiling Hanger role.

2. Highlight Relevant Experience

Emphasize your experience in installing and repairing metal ceilings, as well as any knowledge of construction techniques.

3. Practice Your Answers

Prepare responses to common interview questions related to your skills, experience, and safety practices.

4. Be Enthusiastic and Professional

Show your interest in the position and demonstrate a positive attitude and willingness to learn.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Metal Ceiling Hanger, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Metal Ceiling Hanger positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.