Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Checker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

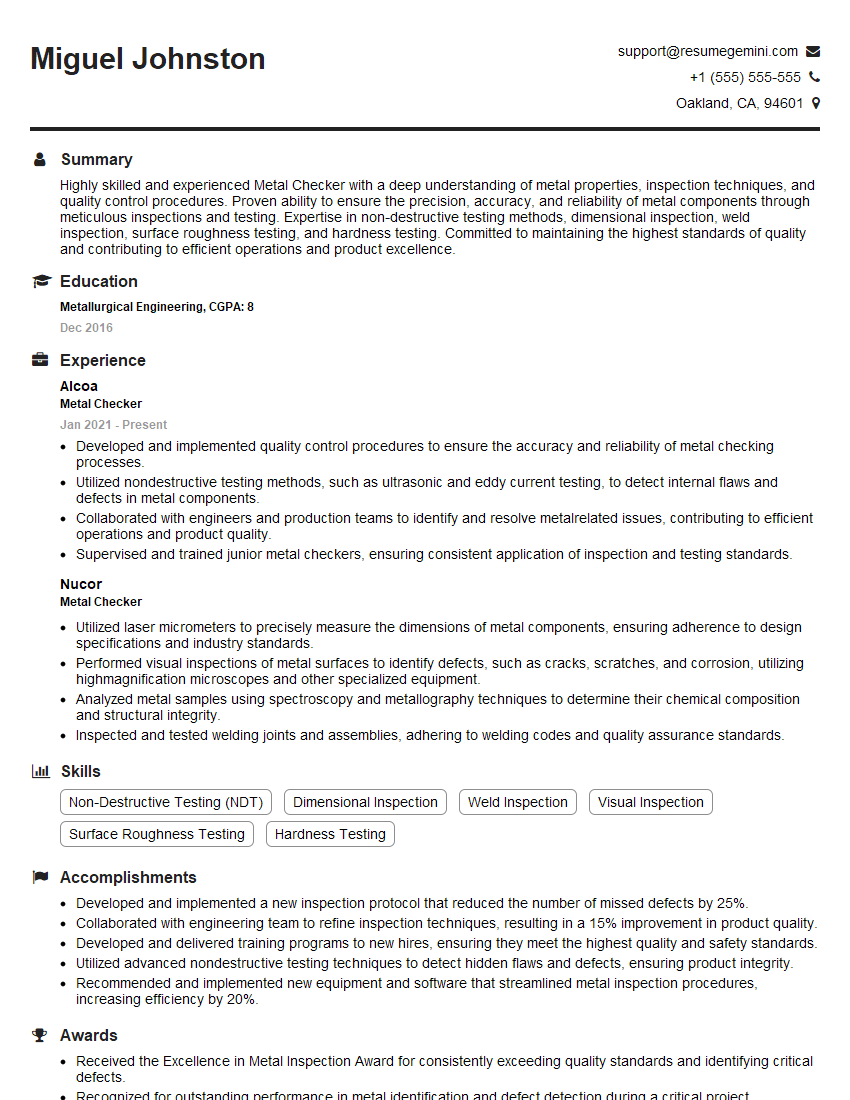

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Checker

1. Explain the different types of metal detectors and their applications?

There are various types of metal detectors, each designed for specific applications. Here are some common types:

- Very Low Frequency (VLF) Detectors: Widely used for detecting buried objects like coins, jewelry, or relics. They operate at low frequencies, making them sensitive to small metal objects.

- Pulse Induction (PI) Detectors: Suitable for searching in highly mineralized areas or underwater. They emit short pulses of electromagnetic energy and detect the decay signal to identify metal objects.

- Beat Frequency Oscillation (BFO) Detectors: Used for precise location and discrimination of metal objects. They create two oscillating circuits and detect changes in frequency caused by the presence of metal.

- Resonance Detectors: Designed to detect specific metals or alloys by matching the resonant frequency of the metal object to the detector’s operating frequency.

- Ground Penetrating Radar (GPR) Detectors: Used for non-invasive subsurface exploration to detect buried objects, utilities, or geological structures.

2. How do you calibrate a metal detector for optimal performance?

Ground Balancing

- Adjust the detector’s ground balance to match the mineralization level of the soil.

- This minimizes false signals caused by ground minerals, allowing for better detection of metal objects.

Discrimination

- Set the detector’s discrimination level to distinguish between desired and unwanted metal targets.

- This helps eliminate false positives and focus on finding specific metal objects.

Sensitivity

- Adjust the detector’s sensitivity to optimize its ability to detect metal objects.

- Higher sensitivity allows for detecting deeper or smaller objects, but it can also increase false signals.

3. Describe the principles of eddy current induction and how it is used in metal detectors?

Eddy current induction is a physical phenomenon where an alternating magnetic field induces electric currents (eddy currents) in a conductive material. In metal detectors, this principle is used to detect metal objects:

- A coil generates an alternating magnetic field, which creates eddy currents in nearby conductive materials.

- The eddy currents generate their own magnetic field, which interacts with the original magnetic field.

- The changes in the magnetic field are detected by the detector, indicating the presence of metal.

4. Explain the factors that affect the depth of penetration of metal detectors?

The depth of penetration of metal detectors is influenced by several factors:

- Frequency: Lower frequencies have greater penetration depth than higher frequencies.

- Soil Conditions: Mineralized soil, high moisture, or salt content can reduce penetration depth.

- Metal Type: Different metals have varying magnetic properties, affecting their detectability.

- Object Size: Larger objects are generally easier to detect at greater depths.

- Detector Coil Size: Larger coils have a wider search area and can detect objects at greater depths.

5. What are the different types of false signals in metal detecting and how do you minimize them?

False signals in metal detecting can arise from various sources:

- Ground Minerals: Highly mineralized soil can produce false signals, which can be minimized by adjusting the detector’s ground balance.

- Electrical Interference: Power lines, electronic devices, or other metal objects can cause electromagnetic interference, which can be reduced by using shielded detectors or adjusting settings.

- Environmental Factors: Temperature changes, moisture, or vegetation can affect the detector’s operation and lead to false signals.

6. How do you identify and differentiate between different types of metal using a metal detector?

Metal detectors can often provide information about the type of metal detected based on its conductivity and magnetic properties:

- Conductivity: Different metals have varying electrical conductivity, which can be detected by the detector’s discrimination circuit.

- Magnetic Properties: Ferrous metals (e.g., iron, steel) are magnetic and can be identified by their strong response to magnetic fields.

- Tone: Some detectors use different audio tones to indicate the type of metal detected.

7. Describe the safety precautions that should be taken while using a metal detector?

Safety precautions are crucial while using a metal detector:

- Avoid Power Lines: Maintain a safe distance from overhead power lines to prevent electrical hazards.

- Check Surroundings: Be aware of your surroundings and avoid digging near buried utilities or other hazards.

- Wear Protective Gear: Use gloves and eye protection when digging to avoid injuries.

- Follow Manufacturer’s Instructions: Carefully read and adhere to the manufacturer’s operating instructions for the specific detector being used.

8. What are the ethical considerations and legal requirements related to metal detecting?

Ethical and legal responsibilities are important in metal detecting:

- Respect Private Property: Obtain permission before searching on private land.

- Follow Local Regulations: Be aware of and comply with local laws and regulations regarding metal detecting.

- Preserve Historical Finds: Report any significant historical artifacts or findings to the appropriate authorities.

- Respect the Environment: Practice responsible digging techniques to minimize environmental impact.

9. What is your experience with using different types of metal detectors and how have you used them to successfully locate metal objects?

Example Answer:

- Described experience with various metal detector types, including VLF, PI, and BFO.

- Shared examples of successful searches where specific detector features were utilized, such as high sensitivity for detecting small objects or ground balancing for mineralized soil.

- Emphasized understanding of detector settings and how to optimize them for different search conditions.

10. How do you stay up-to-date with the latest advancements in metal detector technology and best practices?

Example Answer:

- Mentioned attending industry conferences, workshops, or online courses to enhance knowledge.

- Discussed reading technical articles, manufacturer updates, and online forums to stay informed.

- Expressed eagerness to learn about new technologies and techniques to improve detection capabilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Checker, also known as a Non-Destructive Testing (NDT) Technician, is a quality control professional responsible for ensuring the integrity of metal components and structures through various non-destructive testing methods.

1. Non-Destructive Testing

Conduct various NDT techniques, such as visual inspection, liquid penetrant testing, magnetic particle testing, ultrasonic testing, and radiographic testing, to identify defects, such as cracks, inclusions, and corrosion, without damaging the component or structure.

2. Equipment Operation and Maintenance

Operate and maintain specialized NDT equipment, including ultrasonic flaw detectors, eddy current instruments, and radiography machines, to ensure accurate and reliable testing.

3. Data Analysis and Interpretation

Analyze and interpret NDT test results to determine the extent and severity of defects, assess structural integrity, and recommend appropriate corrective actions.

4. Inspection Documentation

Prepare comprehensive inspection reports that detail the testing procedures, results, and any defects identified. Maintain accurate and thorough records for quality control purposes.

Interview Tips

Preparing for a Metal Checker interview requires thorough knowledge of NDT techniques, industry standards, and quality control procedures. Here are some tips to help candidates ace the interview:

1. Research the Company and Industry

Research the company’s products, services, and reputation in the industry. Understand their quality control processes and the specific NDT methods they use. This demonstrates your interest in the role and the industry.

2. Practice NDT Techniques

Refresh your knowledge and practice NDT techniques before the interview. Be prepared to discuss your experience with different methods and demonstrate your understanding of their applications.

3. Review Industry Standards and Best Practices

Familiarize yourself with relevant industry standards, such as ASTM and ASNT, and discuss how you incorporate them into your inspection practices. This highlights your commitment to quality and compliance.

4. Prepare Examples of Your Work

Bring examples of your previous NDT reports or case studies that showcase your technical skills, analytical abilities, and ability to solve problems effectively.

5. Highlight Your Communication and Teamwork Skills

Emphasize your ability to communicate inspection results clearly to engineers, supervisors, and clients. Discuss your experience working in a team environment and collaborating with others to ensure project success.

6. Ask Informed Questions

Prepare insightful questions about the company’s NDT procedures, equipment used, or recent industry developments. This shows your initiative and interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Checker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.