Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal CNC Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

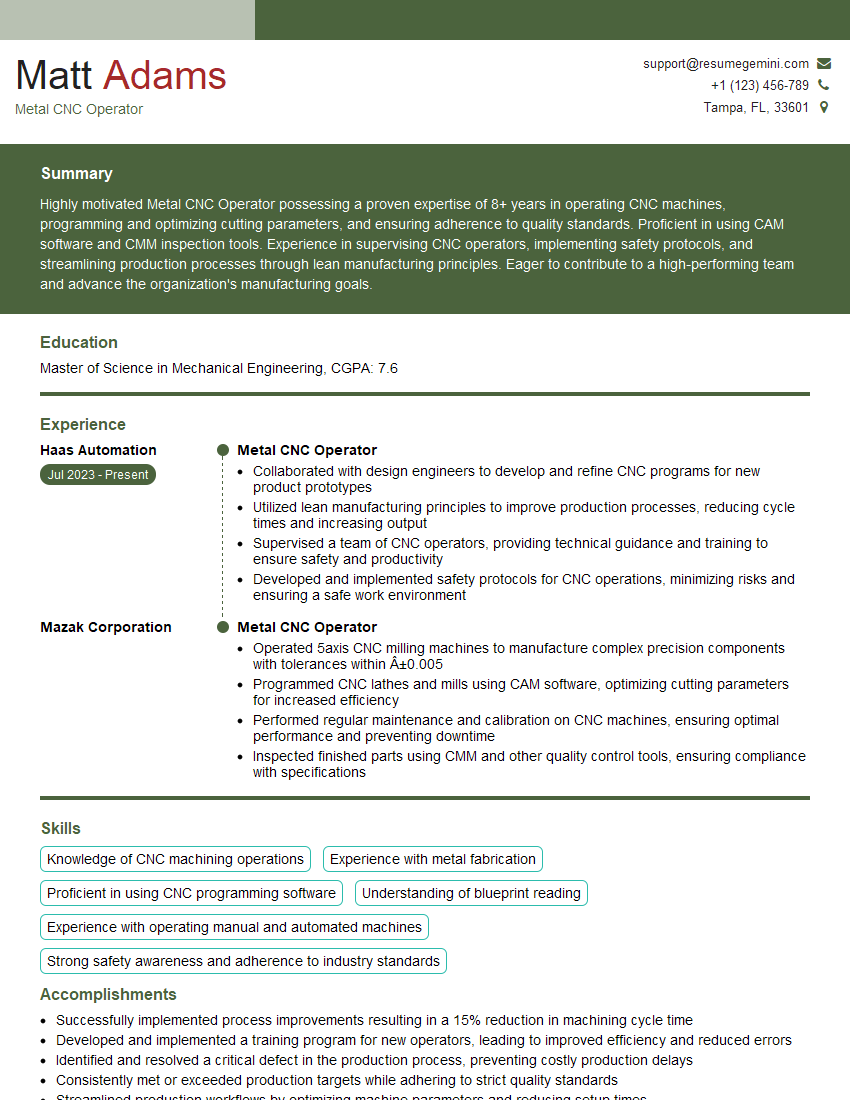

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal CNC Operator

1. What are the different types of CNC machines used for metalworking?

There are several types of CNC machines used for metalworking, including:

- CNC milling machines: Used for cutting and shaping metal by rotating a cutting tool around a fixed workpiece.

- CNC turning machines (lathes): Used for creating cylindrical shapes by rotating a workpiece while a cutting tool moves along its axis.

- CNC drilling machines: Used for creating holes in metal.

- CNC plasma cutters: Used for cutting metal using a plasma torch.

- CNC waterjet cutters: Used for cutting metal using a high-pressure jet of water mixed with abrasive particles.

2. What is G-code and how is it used in CNC programming?

G-code is a numerical control programming language used to instruct CNC machines. It specifies the movements and actions of the machine, such as tool path, speed, and feed rate.

G-code commands include:

- G00: Rapid positioning (non-cutting)

- G01: Linear interpolation (cutting)

- G02: Circular interpolation clockwise

- G03: Circular interpolation counterclockwise

- G28: Home position

3. What is the difference between absolute and incremental positioning?

Absolute positioning: The machine moves to a specific coordinate location based on the machine’s reference point.

Incremental positioning: The machine moves a specified distance relative to its current position.

4. How do you set up and zero a CNC machine?

Setting up and zeroing a CNC machine involves:

- Mounting the workpiece securely.

- Using a touch probe or dial indicator to locate the machine’s reference point.

- Setting the machine’s coordinate system and tool offsets.

- Verifying the setup by running a test program.

5. What are the common problems that can occur during CNC machining and how do you troubleshoot them?

Common problems include:

- Tool breakage: Check for dull or chipped tools, insufficient cutting speed, or excessive feed rate.

- Surface finish issues: Adjust cutting parameters (speed, feed, depth of cut), ensure proper tool selection and lubrication.

- Machine errors: Check for mechanical issues, software malfunctions, or encoder failures.

6. How do you ensure the quality of CNC machined parts?

Quality assurance involves:

- Choosing the right materials and cutting tools.

- Optimizing cutting parameters.

- Performing regular maintenance and calibration of the machine.

- Inspecting parts using measuring instruments and quality control procedures.

7. What experience do you have with CAM software?

CAM (computer-aided manufacturing) software is used to generate G-code from CAD models. Experience with CAM software may include:

- Creating and editing geometry.

- Setting up cutting tools and operations.

- Simulating toolpaths to detect potential collisions.

- Post-processing G-code for specific machine control systems.

8. How do you stay up-to-date with the latest advancements in CNC technology?

Staying up-to-date involves:

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Networking with other CNC professionals.

- Seeking training on new technologies and equipment.

9. What is your approach to working as part of a team?

In a team environment, I prioritize:

- Communication: Effectively sharing information, seeking clarification, and keeping team members informed.

- Collaboration: Working together to solve problems, share knowledge, and achieve common goals.

- Respect: Valuing and recognizing the contributions of others, regardless of their roles or backgrounds.

- Adaptability: Adjusting to changing priorities, adjusting to the needs of the team, and embracing a willingness to learn from others.

10. What are your strengths and weaknesses as a CNC Operator?

Strengths:

- Experience in operating CNC milling and turning machines.

- Proficient in G-code programming and CAM software.

- Strong attention to detail and ability to follow complex instructions.

- Excellent troubleshooting skills and problem-solving abilities.

Weaknesses:

- Limited experience with certain specialized CNC operations.

- Seeking to expand knowledge in advanced CNC techniques and automation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal CNC Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal CNC Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal CNC Operators are responsible for operating and maintaining Computer Numerical Control (CNC) machines to manufacture metal parts and components. They work closely with engineers and designers to ensure that the parts are produced according to specifications. Key job responsibilities include:

1. Programming and Operating CNC Machines

Operate CNC machines by loading programs, setting up workpieces, and monitoring the machining process

- Program and operate CNC machines according to engineering drawings and specifications

- Set up and adjust CNC machines to ensure accuracy and efficiency

2. Quality Control

Inspect finished parts and components to ensure they meet quality standards

- Conduct quality control checks on finished parts and identify any defects

- Calibrate and maintain measuring equipment to ensure accuracy

3. Maintenance and Repair

Perform basic maintenance and repairs on CNC machines

- Clean and lubricate CNC machines regularly

- Identify and resolve minor mechanical and electrical problems

- Perform preventive maintenance to minimize downtime

4. Safety

Follow all safety regulations and procedures

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs

- Maintain a clean and orderly work area

- Operate CNC machines in accordance with established safety protocols

Interview Tips

To ace an interview for a Metal CNC Operator position, it’s important to prepare thoroughly and present yourself as a skilled and knowledgeable candidate. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you’re applying for. This will give you a better understanding of the company’s culture, values, and the specific requirements of the role. You can also prepare tailored answers to questions about why you’re interested in the company and how your skills and experience align with the job description.

2. Practice Your Answers

Once you’ve researched the company and position, start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview itself. Consider practicing with a friend, family member, or career counselor for feedback and support.

3. Showcase Your Skills and Experience

In your answers, be sure to highlight your relevant skills and experience. For example, you can provide examples of times when you successfully operated and maintained CNC machines, conducted quality control checks, or resolved technical issues. Use specific examples and quantifiable results to demonstrate your abilities.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. Prepare a few questions about the company, the position, or the industry. This is also an opportunity to clarify any information or ask for more details about the role.

5. Follow Up

After the interview, follow up with the interviewer via email or a handwritten note. Thank them for their time and reiterate your interest in the position. You can also use this opportunity to address any questions or concerns that may have come up during the interview.

Next Step:

Now that you’re armed with the knowledge of Metal CNC Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal CNC Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini