Feeling lost in a sea of interview questions? Landed that dream interview for Metal Control Coordinator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Control Coordinator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

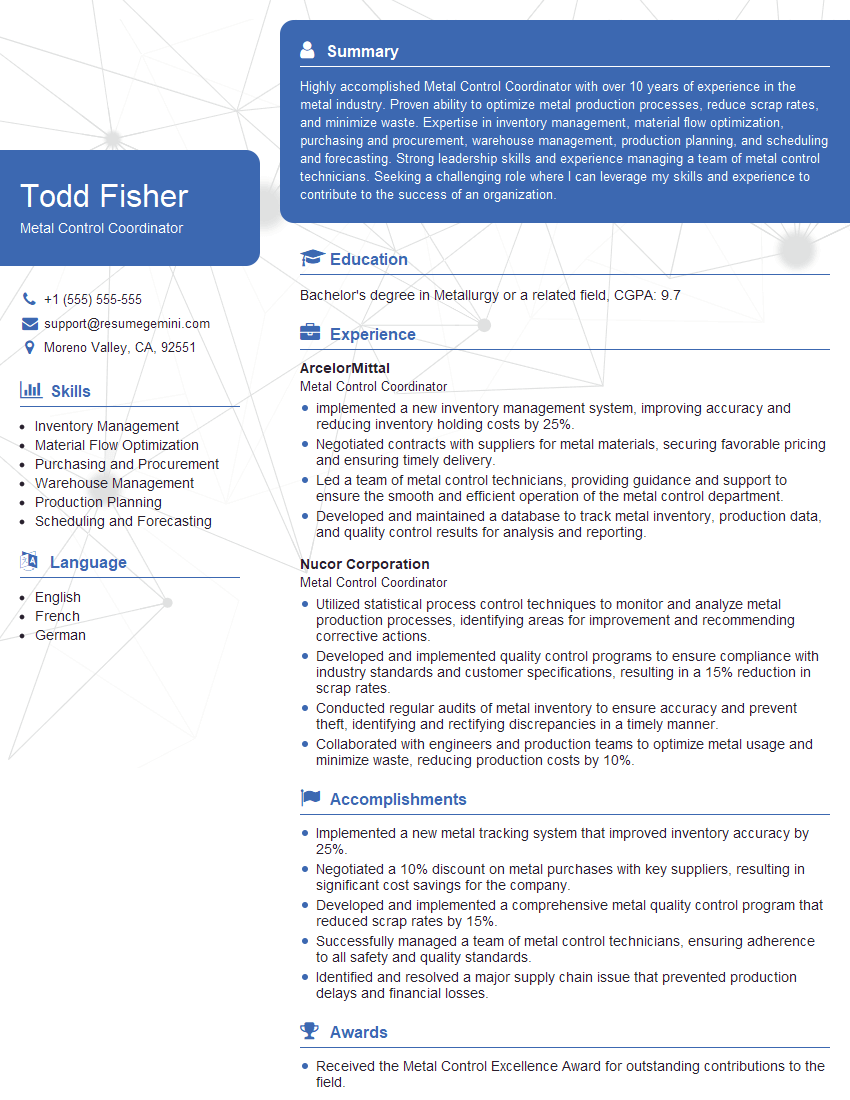

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Control Coordinator

1. Explain the significance of maintaining accurate and up-to-date production records in metal control?

Accurate and up-to-date production records are crucial for metal control because they:

- Provide a clear picture of the current metal inventory, enabling effective planning for future production.

- Facilitate the tracking of metal usage and consumption, allowing for cost analysis and optimization.

- Identify discrepancies and potential errors in the production process, facilitating timely corrective actions.

- Serve as historical data for future reference, enabling the analysis of trends and patterns in production.

- Enhance regulatory compliance by providing auditable records.

2. Describe the typical steps involved in the metal control process.

Receiving

- Inspecting incoming metal shipments for quantity and quality.

- Recording the receipt of metal in inventory systems.

- Assigning unique identification numbers or tags for traceability.

Storage

- Maintaining organized and secure storage areas for different types of metals.

- Implementing inventory management systems to track stock levels and locations.

- Ensuring proper storage conditions to prevent contamination or damage.

Issuance

- Issuing metals to production based on authorized requests.

- Recording the issuance of metals in inventory systems.

- Verifying the return of unused metals or scrap.

Inventory Reconciliation

- Periodically reconciling inventory records with physical counts.

- Investigating and resolving any discrepancies identified.

- Making necessary adjustments to inventory records.

3. How do you ensure the quality of metals used in production? What standards and certifications are relevant?

Quality assurance of metals in production involves:

- Establishing and adhering to quality specifications for incoming metals.

- Conducting regular inspections and testing to verify compliance with standards.

- Implementing supplier qualification processes to ensure the reliability of metal suppliers.

- Maintaining certifications and accreditations relevant to the industry and metal types used, such as:

- ISO 9001 Quality Management System

- AS9100 Aerospace Quality Management System

- MIL-STD-883 Military Standard for Microelectronics

- ASTM International Standards for materials testing

4. Describe the different inventory management techniques used in metal control.

- First-In, First-Out (FIFO): Assumes that the oldest inventory is used first.

- Last-In, First-Out (LIFO): Assumes that the newest inventory is used first.

- Weighted Average Cost: Calculates the average cost of inventory based on all purchases.

- Specific Identification: Tracks the cost of each individual inventory item.

- Just-In-Time (JIT): Minimizes inventory levels by receiving materials as close to the production process as possible.

5. How do you handle and track scrap metal generated during production?

Managing scrap metal involves:

- Identifying and segregating scrap metal by type and grade.

- Establishing procedures for the collection and storage of scrap metal.

- Implementing a weighing and tracking system to monitor scrap metal quantities.

- Exploring opportunities for scrap metal recycling or sale to generate revenue.

6. What role does automation play in modern metal control systems?

Automation in metal control systems:

- Streamlines receiving and issuance processes through barcode or RFID technology.

- Provides real-time inventory visibility using inventory management software.

- Automates inventory reconciliation and discrepancy analysis.

- Improves traceability through electronic documentation and record-keeping.

- Enhances efficiency and reduces errors in metal control operations.

7. How do you stay updated on industry best practices and regulations related to metal control?

To stay updated on best practices and regulations:

- Attend industry conferences and seminars.

- Read trade publications and journals.

- Participate in professional organizations related to metal control.

- Review and comply with applicable industry standards and regulatory requirements.

- Seek continuing education opportunities through workshops or online courses.

8. Describe a challenging situation you faced in metal control and how you resolved it.

In a previous role, I encountered a discrepancy between inventory records and physical counts. To resolve this, I:

- Contacted the supplier to verify delivery records.

- Conducted a thorough physical inventory count with assistance from the production team.

- Reviewed production records to identify any unaccounted for metal usage.

- Identified an error in the inventory management system that had resulted in the discrepancy.

- Made necessary corrections to the system and implemented additional measures to prevent similar errors in the future.

9. How do you prioritize and manage multiple tasks in a fast-paced metal control environment?

In a fast-paced environment, I prioritize tasks based on:

- Urgency and impact on production.

- Deadlines and commitments to customers.

- Availability of resources and support.

- Potential risks or consequences of delays.

I use a combination of tools and techniques to manage multiple tasks effectively:

- Task management software or spreadsheets.

- Regularly reviewing my priorities and adjusting as needed.

- Delegating tasks to team members when appropriate.

- Communicating regularly with stakeholders to provide updates and address any concerns.

10. How do you ensure that metal control processes are aligned with overall business objectives?

To align metal control processes with business objectives, I:

- Collaborate with management to understand the company’s strategic goals.

- Map metal control processes to specific business objectives, such as cost reduction, inventory optimization, or quality improvement.

- Regularly review and adjust metal control processes to ensure alignment with changing business needs.

- Measure and track key performance indicators (KPIs) to monitor progress and identify areas for improvement.

- Communicate the impact of metal control processes on overall business performance to stakeholders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Control Coordinator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Control Coordinator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Control Coordinators play a pivotal role in ensuring the smooth and efficient flow of metal products within a company. Their responsibilities encompass a wide range of tasks, including:

1. Inventory Management

Maintaining accurate and up-to-date records of metal inventory levels, including raw materials, work-in-process, and finished goods. Conducting regular inventory audits to ensure accuracy and prevent discrepancies.

- Coordinate with suppliers to ensure timely delivery of materials.

- Monitor inventory levels and identify potential shortages or overstocking.

2. Production Planning and Scheduling

Collaborating with production departments to plan and schedule metal fabrication and processing operations. Estimating material requirements and lead times for production orders.

- Develop production schedules based on customer orders and inventory availability.

- Coordinate with production teams to ensure timely completion of orders.

3. Quality Control and Inspection

Implementing and enforcing quality control measures to ensure that metal products meet specifications. Inspecting incoming and outgoing metal materials for defects or non-conformances.

- Establish quality standards and procedures for metal products.

- Conduct regular inspections of metal products to ensure compliance with standards.

4. Logistics and Shipping

Managing the logistics of metal product transportation, including shipping and receiving. Coordinating with carriers and freight forwarders to ensure timely and cost-effective delivery.

- Plan and coordinate the shipment of metal products to customers.

- Negotiate shipping rates and manage logistics to minimize transportation costs.

Interview Tips

To ace the interview for a Metal Control Coordinator position, it’s crucial to demonstrate a comprehensive understanding of the role and its responsibilities. Here are some tips to help you prepare:

1. Research the Company and Industry

Familiarize yourself with the company’s background, products, and industry trends. This will enable you to align your experience and skills with the company’s specific requirements.

- Visit the company website and social media pages to gather information about their operations and culture.

- Read industry publications and news articles to stay updated on the latest developments in metal processing and manufacturing.

2. Highlight Relevant Experience and Skills

Emphasize your experience in inventory management, production scheduling, quality control, and logistics. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- For instance, you could mention the percentage increase in inventory accuracy you achieved through implementing a new inventory tracking system.

- Showcase your ability to work effectively in a fast-paced and demanding environment.

3. Prepare for Technical Questions

Anticipate questions related to metal products, manufacturing processes, and quality control techniques. Refresh your knowledge of industry-specific terminology and standards.

- Be prepared to discuss your understanding of different types of metals, their properties, and applications.

- Practice answering questions about inventory management systems, production planning techniques, and quality control procedures.

4. Demonstrate Your Communication and Interpersonal Skills

Metal Control Coordinators often interact with various departments and stakeholders. Highlight your ability to communicate effectively, build strong relationships, and resolve conflicts.

- Share examples of how you successfully collaborated with cross-functional teams to achieve common goals.

- Emphasize your ability to communicate complex technical information clearly and concisely.

5. Practice Your Answers

Practicing your answers to common interview questions will boost your confidence and help you deliver clear and concise responses. Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- For instance, you could prepare an answer to the question “Tell me about a time you resolved a quality issue” using the STAR method.

- Consider asking a friend or family member to mock interview you to gain feedback and improve your presentation.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Control Coordinator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.