Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Die Finisher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Die Finisher so you can tailor your answers to impress potential employers.

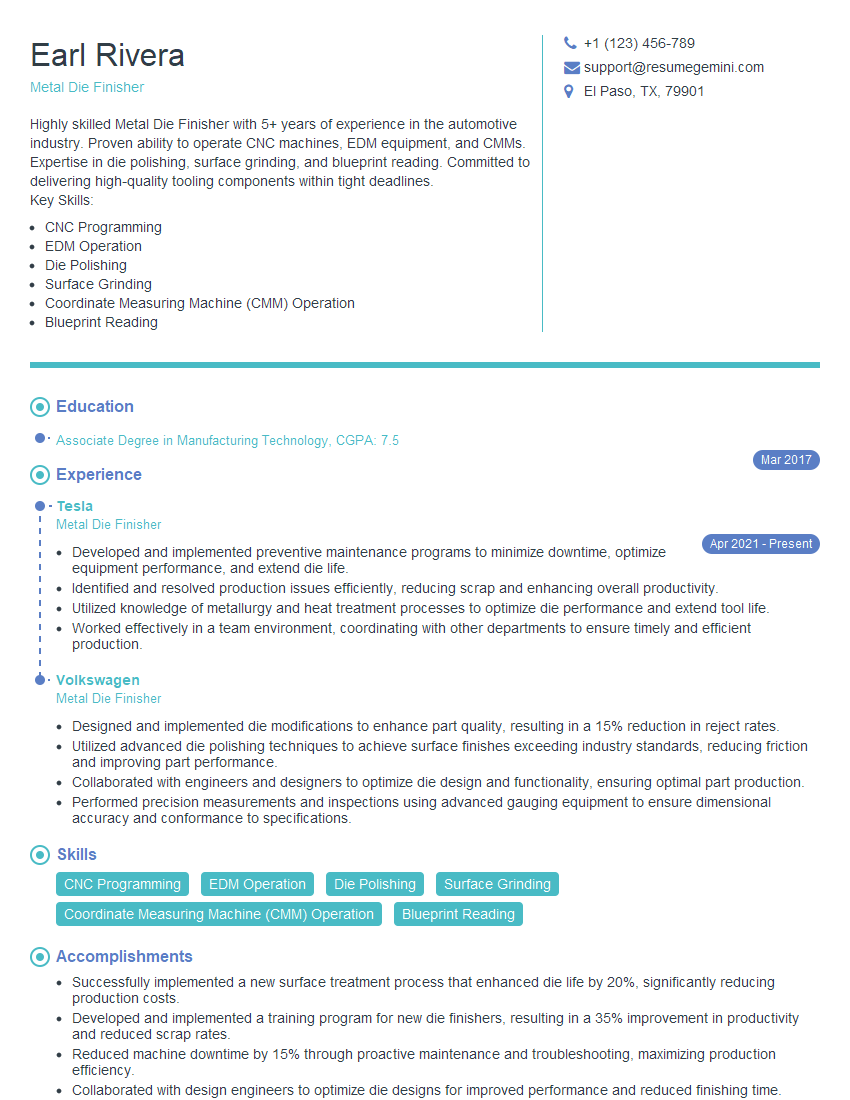

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Die Finisher

1. Describe the steps involved in the metal die finishing process?

The metal die finishing process typically involves several key steps:

- Deburring: Removing sharp edges or burrs from the die using tools like files, wire brushes, or abrasive wheels.

- Polishing: Smoothing and refining the die surface using abrasive materials like sandpaper, grinding wheels, or polishing compounds.

- Honing: Creating a fine, precise finish on the die using specialized honing stones or tools.

- Lapping: Achieving an ultra-smooth surface by using fine abrasives and a flat surface.

- Checking and Inspection: Thoroughly inspecting the finished die to ensure it meets the desired specifications and quality standards.

2. What are the different types of metal die finishing techniques and when are they used?

There are several metal die finishing techniques used for various purposes:

Deburring Techniques

- Hand Deburring: Using manual tools like files or scrapers for small-scale or intricate deburring.

- Mechanical Deburring: Utilizing power tools or machines for faster and more efficient deburring.

- Chemical Deburring: Dissolving burrs using chemical solutions.

Polishing Techniques

- Mechanical Polishing: Using abrasive belts, wheels, or brushes to remove material and smooth surfaces.

- Chemical Polishing: Employing chemical solutions to dissolve and remove surface imperfections.

- Electrolytic Polishing: Using an electrolytic process to achieve a bright, smooth finish.

3. How do you ensure the accuracy and precision of finished dies?

To ensure accuracy and precision, I follow these practices:

- Proper Measurement and Inspection: Using precision measuring tools (e.g., calipers, micrometers) and optical comparators to verify dimensions and tolerances.

- Calibration and Maintenance: Regularly calibrating and maintaining finishing equipment to ensure optimal performance and accuracy.

- Quality Control: Implementing quality control measures throughout the process, including regular inspections and documentation.

- Continuous Improvement: Seeking opportunities to refine techniques and improve the overall finishing process.

4. What are the common defects that can occur during metal die finishing and how do you prevent them?

Potential defects and preventive measures include:

- Burrs: Implement effective deburring techniques and ensure proper tool selection.

- Surface Scratches: Use appropriate abrasives and avoid excessive pressure during polishing.

- Dimensional Inaccuracy: Utilize precise measuring tools and maintain consistent finishing parameters.

- Corrosion: Apply protective coatings or finishes to prevent oxidation and ensure durability.

5. Describe your experience in working with different types of metals and alloys in die finishing.

I have experience with various metals and alloys used in die manufacturing, including:

- Steels: Carbon steels, stainless steels, and tool steels

- Aluminum alloys: 6000 and 7000 series

- Brass and Bronze

- Carbide and Tungsten

6. What are the safety precautions you observe while working in a metal die finishing environment?

I prioritize safety by adhering to these precautions:

- Proper Personal Protective Equipment (PPE): Wearing safety glasses, gloves, and appropriate clothing.

- Machine Guarding: Ensuring all machinery has proper guards and safety interlocks.

- Ventilation: Maintaining adequate ventilation to remove dust and fumes.

- Safe Handling and Storage: Correctly handling and storing chemicals and materials.

7. How do you stay updated with the latest advancements in metal die finishing technology?

To keep abreast of industry developments, I engage in the following practices:

- Industry Publications: Reading trade magazines and journals.

- Conferences and Webinars: Attending industry events and participating in online seminars.

- Networking: Connecting with other professionals and experts in the field.

- Manufacturer Training: Undergoing training provided by equipment and material manufacturers.

8. What are your quality control standards for metal die finishing?

My quality control standards encompass the following:

- Dimensional Accuracy: Verifying dimensions and tolerances meet specifications.

- Surface Finish Quality: Ensuring a smooth and defect-free surface finish.

- Material Integrity: Inspecting for cracks, voids, or other defects.

- Documentation: Maintaining detailed records of inspection results and finished die specifications.

9. How do you handle customer feedback and complaints related to metal die finishing?

When addressing customer feedback or complaints, I follow these steps:

- Active Listening: Carefully listening to the customer’s concerns and acknowledging their perspective.

- Investigation: Conducting a thorough investigation to determine the root cause of the issue.

- Corrective Action: Implementing measures to address the problem and prevent its recurrence.

- Communication: Keeping the customer informed throughout the process and providing timely updates.

10. What is your approach to continuous improvement in metal die finishing?

I am committed to continuous improvement through:

- Process Analysis: Regularly reviewing and analyzing finishing processes to identify areas for optimization.

- Technology Adoption: Exploring and implementing new technologies to enhance efficiency and quality.

- Training and Development: Seeking opportunities for professional development and training to refine skills.

- Collaboration: Working with colleagues and industry experts to share knowledge and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Die Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Die Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Die Finishers are responsible for ensuring that metal dies are finished to exact specifications, which requires a high degree of precision and attention to detail. Key job responsibilities include:

1. Die Preparation

Preparing dies for finishing by cleaning, inspecting, and polishing them.

- Ensuring that dies are free of any defects or damage.

- Polishing dies to achieve a smooth, mirror-like finish.

2. Die Finishing

Finishing dies using a variety of techniques, including grinding, honing, and lapping.

- Grinding dies to remove excess material and achieve the desired shape.

- Honing dies to create a smooth, precise surface.

- Lapping dies to achieve a mirror-like finish.

3. Quality Control

Inspecting finished dies to ensure that they meet all specifications.

- Measuring dies to ensure that they are within tolerance.

- Examining dies for any defects or imperfections.

4. Maintenance

Maintaining the equipment used for die finishing, including grinders, hones, and lappers.

- Cleaning and lubricating equipment.

- Inspecting equipment for any signs of wear or damage.

- Performing minor repairs and adjustments.

Interview Tips

Preparing for an interview for a Metal Die Finisher position requires research, practice, and a positive attitude. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website and read about their products, services, and history.

- Look for news articles or industry reports that mention the company.

- Review the job description carefully and identify the key skills and qualifications required.

2. Practice Your Answers

Practice answering common interview questions out loud. This will help you feel more confident and prepared during the actual interview.

- Start by practicing basic questions about your experience and qualifications.

- Then, move on to more specific questions about your skills and knowledge.

- Finally, practice answering behavioral questions that ask you to describe how you have handled specific situations.

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing a suit or business casual attire.

- Make sure your clothes are clean, pressed, and fit well.

- Choose neutral colors and avoid wearing anything too revealing or distracting.

4. Be Punctual

Punctuality shows that you respect the interviewer’s time and that you are organized and reliable.

- Plan your route ahead of time and give yourself plenty of time to get to the interview location.

- If you do happen to be running late, call or email the interviewer to let them know.

5. Be Yourself

It is important to be yourself during an interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic in your answers.

- Show the interviewer your personality and enthusiasm for the position.

Next Step:

Now that you’re armed with the knowledge of Metal Die Finisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal Die Finisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini