Feeling lost in a sea of interview questions? Landed that dream interview for Metal Engraver but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Metal Engraver interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

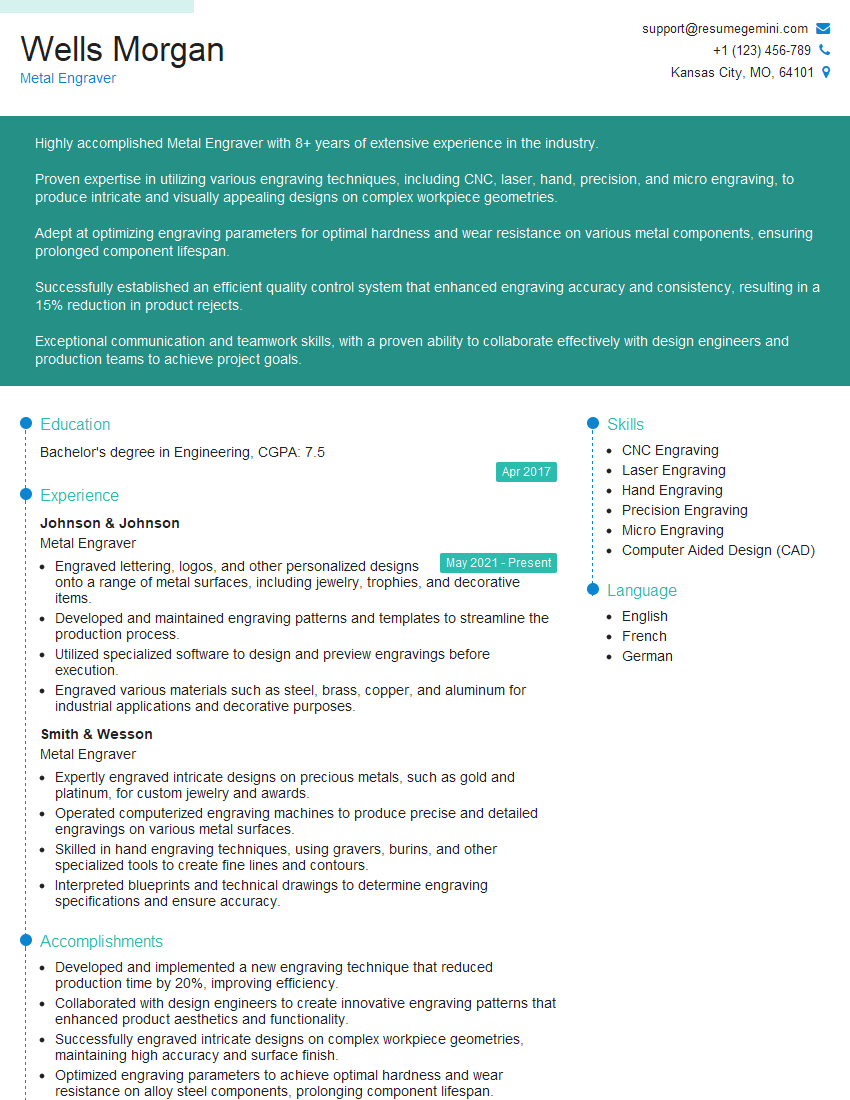

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Engraver

1. What are the different types of metal engraving techniques you are familiar with?

- Hand Engraving: Uses a variety of hand tools to create intricate designs by removing metal from the surface.

- Machine Engraving: Employs machines like CNC engravers to create precise and detailed engravings with higher production rates.

- Laser Engraving: Uses a laser beam to etch designs onto metal surfaces, offering high precision and automation.

- Chemical Etching: Involves using acids or other chemicals to dissolve metal, creating recessed designs.

- Electrochemical Etching: Similar to chemical etching, but uses an electric current to control the metal removal process.

- Dot Peening: Creates engravings by hammering small dots into the metal surface, forming images or text.

2. What factors should be considered when selecting the appropriate engraving technique for a particular project?

- Metal Type: Different metals have varying hardness and workability, affecting the choice of engraving technique.

- Design Complexity: Intricate designs may require more precise techniques like laser or CNC engraving, while simpler designs can be hand engraved.

- Production Volume: High volume projects may benefit from automated techniques like machine or laser engraving for efficiency.

- Budget and Time Constraints: The cost and time required for different techniques must be considered within the project’s budget and schedule.

- Desired Finish: The desired surface finish, such as polished, textured, or matte, can influence the choice of engraving technique.

3. How do you ensure the accuracy and precision of your engravings?

- Precise Tools and Equipment: Using high-quality engraving tools and machines ensures accurate cutting and detailing.

- Detailed Planning and Design: Meticulous planning and design, including the use of templates or CAD software, helps achieve precision.

- Careful Execution: Skilled execution and attention to detail throughout the engraving process contribute to accuracy.

- Quality Control Measures: Regularly checking and measuring engravings against specifications ensures accuracy.

- Experience and Practice: Continuous practice and refinement of techniques develop accuracy and proficiency.

4. Describe your process for creating a metal engraving from start to finish.

- Design Concept and Planning: Understanding the design and preparing necessary tools and materials.

- Metal Preparation: Cleaning and preparing the metal surface for optimal engraving.

- Template or Layout: Transferring the design to the metal using a template or marking techniques.

- Engraving Execution: Using appropriate tools and techniques to create the desired engravings.

- Polishing and Finishing: Refining the surface, removing any imperfections, and applying desired finishes.

- Quality Control: Inspecting and ensuring the engraving meets specifications and customer requirements.

5. How do you handle complex engraving projects that require multiple techniques or materials?

- Project Planning and Analysis: Carefully evaluating the project’s requirements and determining the best combination of techniques.

- Collaboration and Expertise: Consulting with colleagues or seeking external expertise to ensure all aspects of the project are covered.

- Testing and Refinement: Experimenting with different techniques and materials on smaller sections to optimize results.

- Phased Approach: Breaking down the project into manageable phases, allowing for quality control and flexibility.

- Continuous Learning: Researching and staying updated on new techniques and materials to enhance project outcomes.

6. How do you stay up to date with the latest engraving technologies and techniques?

- Industry Publications and Events: Attending trade shows and reading industry magazines to stay informed about new developments.

- Online Resources: Exploring manufacturer websites and forums for technical updates and discussions.

- Training and Workshops: Participating in workshops and courses to enhance skills and knowledge.

- Networking and Collaboration: Connecting with other engravers and professionals to share experiences and learn from industry experts.

- Research and Experimentation: Dedicating time to researching new techniques and experimenting with advanced technologies.

7. How do you ensure the safety of yourself and others while working with metal engraving tools and equipment?

- Proper Safety Gear: Wearing appropriate safety glasses, gloves, and clothing to protect from debris, sparks, and fumes.

- Workplace Maintenance: Keeping the workspace clean, organized, and free of tripping hazards.

- Tool Maintenance and Inspection: Regularly inspecting and maintaining tools and equipment to ensure proper functioning.

- Ventilation and Fume Control: Utilizing proper ventilation systems to remove harmful fumes and dust.

- Safe Operating Procedures: Following established operating procedures and manufacturer guidelines for all tools and machinery.

8. What are the common challenges you encounter in metal engraving and how do you overcome them?

- Material Hardness: Overcoming the hardness of certain metals by using specialized tools and techniques, such as diamond-tipped cutters.

- Intricate Designs: Executing complex designs with precision by utilizing magnification tools, steady hands, and careful planning.

- Tool Wear and Breakage: Minimizing tool wear and breakage by using durable materials, proper lubrication, and regular maintenance.

- Time Constraints: Meeting deadlines by optimizing workflow, using efficient techniques, and prioritizing tasks.

- Customer Expectations: Exceeding customer expectations by understanding their needs, communicating effectively, and delivering high-quality results.

9. How do you handle feedback and criticism on your engraving work?

- Positive Attitude: Approaching feedback with a positive mindset, seeing it as an opportunity for improvement.

- Active Listening: Paying attention to feedback, asking clarifying questions, and understanding the perspective of others.

- Constructive Analysis: Evaluating feedback objectively, identifying areas for improvement, and developing a plan for growth.

- Communication: Openly communicating with clients or colleagues to clarify expectations and address concerns.

- Continuous Improvement: Using feedback to enhance skills, refine techniques, and deliver better results in the future.

10. Why are you interested in working as a Metal Engraver for our company?

- Company Reputation: Expressing admiration for the company’s reputation for quality craftsmanship and customer satisfaction.

- Product Line: Showcasing interest in the company’s product line and the opportunity to contribute to their creation.

- Growth Opportunities: Demonstrating enthusiasm for the company’s commitment to employee growth and development.

- Team Culture: Highlighting the company’s collaborative and supportive team environment.

- Personal Goals: Aligning the company’s values and goals with personal career aspirations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Engraver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Engraver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Metal Engraver

Metal engravers create intricate designs and images on metal surfaces using specialized tools and techniques. They are responsible for a variety of tasks, including:

1. Design and Layout

Engravers typically work from designs created by other artists or customers. They must be able to interpret these designs and create layouts that will translate well to the metal surface. They also need to be able to create their own designs.

2. Engraving

Engravers use a variety of tools to create designs on metal surfaces. These tools include hand-held engraving tools, rotary tools, and laser engravers. Engravers must be able to use these tools with precision and accuracy to create intricate designs.

3. Finishing

Once the engraving is complete, engravers must finish the metal surface. This may involve polishing, plating, or painting the metal to protect it from corrosion and wear.

4. Inspection

Engravers must inspect their work carefully to ensure that it meets the required standards. They must be able to identify and correct any errors.

Interview Tips for Metal Engravers

To ace an interview for a metal engraver position, candidates should prepare thoroughly and demonstrate their skills and experience in the field. Here are some tips to help candidates prepare for the interview:

1. Research the Company and Position

Before the interview, candidates should research the company and the specific position they are applying for. This will help them understand the company’s culture, values, and goals, and it will also help them tailor their answers to the specific requirements of the position.

2. Practice Your Skills

Candidates should practice their engraving skills before the interview. They should be able to demonstrate their proficiency in using different engraving tools and techniques.

3. Prepare a Portfolio

Candidates should bring a portfolio of their work to the interview. This will give the interviewer a chance to see the quality of their work and their attention to detail. The same can be presented during video conferencing if the interview is being taken online.

4. Be Prepared to Talk About Your Experience

Candidates should be prepared to talk about their experience in metal engraving. They should be able to discuss their skills, techniques, and knowledge of the industry.

5. Be Enthusiastic and Professional

Candidates should be enthusiastic about the position and about metal engraving in general. They should also be professional and polite during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Engraver interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.