Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Fabricating Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Fabricating Supervisor so you can tailor your answers to impress potential employers.

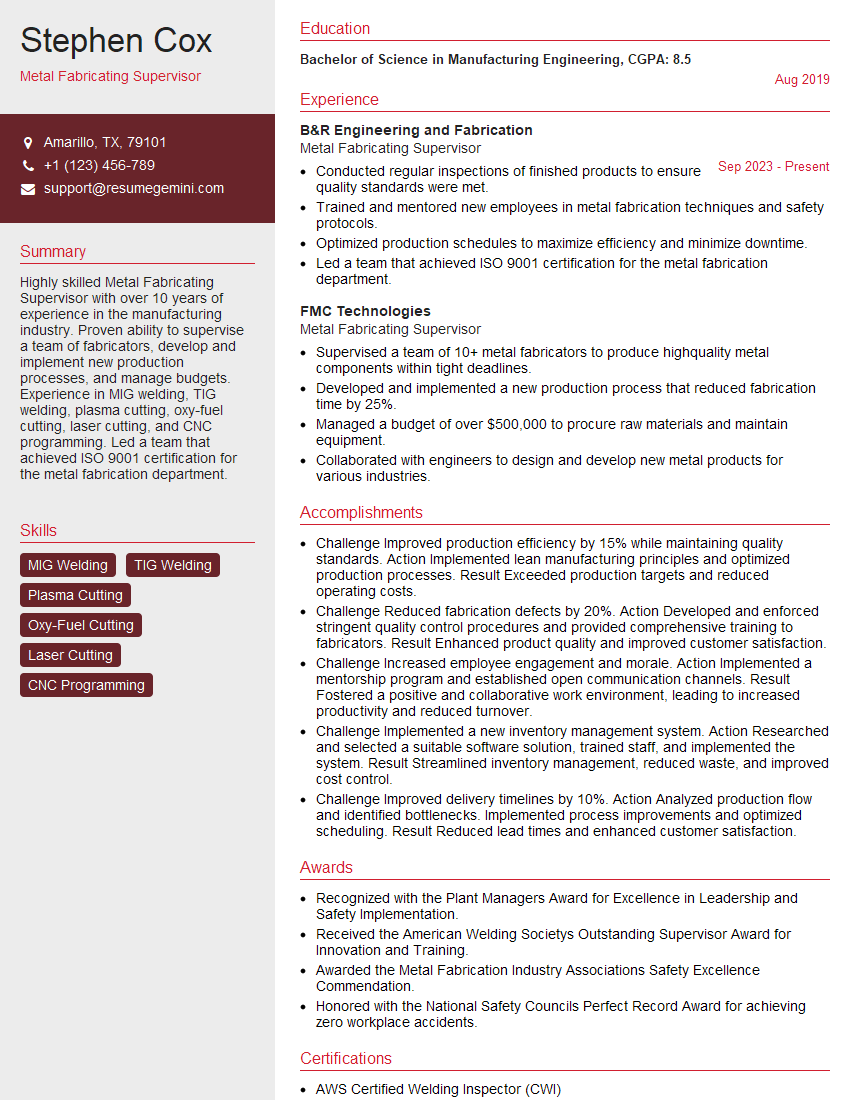

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Fabricating Supervisor

1. Can you explain the process of aluminum welding?

In aluminum welding, the process involves joining aluminum pieces together using heat and a suitable filler metal. The steps are as follows:

- Preparation: The aluminum surfaces are cleaned to remove any impurities or oxides that may hinder the welding process.

- Gas Selection: A shielding gas such as argon or helium is used to protect the weld area from atmospheric contamination.

- Welding: Using a welding torch, the metal is heated to a molten state, and the filler metal is added to create the weld joint.

- Cooling: The welded joint is allowed to cool slowly to reduce the risk of cracking or warping.

2. How do you ensure the dimensional accuracy and quality of fabricated metal parts?

Inspection and Measurement:

- Using precision measuring instruments such as calipers, micrometers, and CMMs (Coordinate Measuring Machines).

- Establishing quality control checkpoints throughout the fabrication process.

Design Verification:

- Reviewing design specifications and drawings for accuracy.

- Conducting dimensional audits and checking part tolerances.

Process Monitoring:

- Regularly calibrating and maintaining fabrication equipment.

- Implementing statistical process control techniques to monitor and adjust production processes.

Supplier Management:

- Qualifying and approving suppliers based on their quality standards.

- Conducting incoming material inspections to verify conformance to specifications.

3. What are the safety protocols for working with heavy machinery used in metal fabrication?

- Training and Certification: Ensuring all operators are adequately trained and certified for the equipment they operate.

- Hazard Assessment: Conducting thorough hazard assessments for each machine and developing appropriate safety procedures.

- Machine Guarding: Installing and maintaining proper machine guards and safety devices to prevent contact with moving parts.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE, such as safety glasses, gloves, and earplugs, to protect against hazards.

- Lockout/Tagout Procedures: Implementing clear lockout/tagout procedures before performing maintenance or repairs on equipment.

4. How do you manage a team of metal fabricators to optimize productivity and efficiency?

- Communication and Collaboration: Establishing clear communication channels and fostering collaboration among team members.

- Work Allocation and Scheduling: Assigning tasks based on skillset and ensuring efficient scheduling to minimize downtime.

- Performance Monitoring: Setting performance metrics and regularly tracking progress against targets to identify areas for improvement.

- Continuous Training and Development: Providing opportunities for skill enhancement and professional development to enhance team capabilities.

- Reward and Recognition: Recognizing and rewarding team members for their contributions and achievements to motivate and maintain high performance.

5. What techniques do you use to minimize scrap and waste in your fabrication processes?

- Material Optimization: Utilizing advanced software to optimize material usage and minimize waste.

- Efficient Cutting Methods: Employing techniques such as nesting and laser cutting to minimize material loss during cutting operations.

- Process Standardization: Establishing standardized processes to reduce variation and ensure consistent quality, thus minimizing the likelihood of scrap.

- Waste Management and Recycling: Implementing a waste management system to segregate and recycle scrap materials, reducing disposal costs and environmental impact.

- Lean Manufacturing Principles: Adopting lean manufacturing principles, such as continuous improvement and waste reduction, to identify and eliminate inefficiencies in the fabrication process.

6. How do you handle customer complaints or concerns regarding fabricated metal parts?

- Responsive Communication: Responding promptly and professionally to customer complaints, acknowledging the concerns and expressing willingness to resolve the issue.

- Root Cause Analysis: Conducting a thorough root cause analysis to identify the underlying cause of the complaint and prevent recurrence.

- Corrective Actions: Implementing corrective actions to address the complaint and improve product quality or service.

- Customer Follow-Up: Providing regular updates to the customer on the progress of the complaint resolution and seeking their feedback.

- Continuous Improvement: Utilizing customer feedback and complaints as valuable opportunities to identify areas for continuous improvement in the fabrication process.

7. What software and technologies are you proficient in using for metal fabrication?

- CAD/CAM Software: Proficient in using computer-aided design (CAD) and computer-aided manufacturing (CAM) software for design and programming.

- ERP Systems: Knowledge of enterprise resource planning (ERP) systems for inventory management, production planning, and quality control.

- Measurement and Inspection Equipment: Familiar with the operation and calibration of measurement and inspection equipment, such as CMMs and optical comparators.

- Welding and Fabrication Techniques: In-depth knowledge of welding techniques, such as MIG, TIG, and plasma cutting, as well as metal fabrication processes.

8. How do you stay updated with advancements in metal fabrication technologies and industry best practices?

- Industry Conferences and Exhibitions: Attending industry conferences, exhibitions, and workshops to learn about new technologies, techniques, and best practices.

- Trade Publications and Journals: Subscribing to trade publications and industry journals to stay informed about industry trends, innovations, and case studies.

- Professional Development Courses: Pursuing professional development courses, certifications, and training programs to enhance knowledge and skills.

- Collaboration and Networking: Connecting with industry peers, experts, and vendors to exchange knowledge and stay abreast of emerging technologies.

9. How do you motivate and engage your team to achieve optimal performance?

- Clear Goals and Expectations: Setting clear and achievable goals and expectations for the team, ensuring they are aligned with the company’s objectives.

- Recognition and Appreciation: Recognizing and appreciating the team’s efforts, accomplishments, and contributions to foster a positive and motivated work environment.

- Empowerment and Responsibility: Empowering team members by delegating responsibilities, providing autonomy, and fostering a sense of ownership.

- Communication and Feedback: Maintaining open and transparent communication channels, providing regular feedback, and encouraging team input to improve performance.

- Team Building and Collaboration: Building a strong team culture through team-building activities, encouraging collaboration, and fostering a supportive work environment.

10. Can you provide an example of a successful project you led in metal fabrication? What were the challenges and how did you overcome them?

Project: Design and fabrication of a complex metal assembly for a heavy-duty industrial machine.

Challenges:

- Intricate design with tight tolerances.

- Limited access to specialized equipment.

- Time constraints and budget limitations.

How I Overcame Them:

- Collaborated with the engineering team to optimize the design for manufacturability.

- Sought out alternative suppliers and negotiated lower costs for materials and services.

- Implemented innovative fabrication techniques to improve efficiency and accuracy.

- Coordinated with the production team to ensure timely delivery and minimize disruptions.

Outcome:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Fabricating Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Fabricating Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Lead and Supervise a Team

Playing a lead role, managing and directing metal fabricators to ensure maximum efficiency and productivity in all operations.

2. Production Planning and Monitoring

Planning production schedules, allocating resources, and monitoring progress to meet production goals and deadlines.

3. Quality Control and Assurance

Maintaining high quality standards by implementing and enforcing quality control measures, inspecting finished products, and addressing customer concerns.

4. Safety and Compliance

Enforcing safety regulations, monitoring work areas for hazards, and ensuring compliance with all environmental and safety protocols.

5. Training and Development

Providing guidance, training, and support to team members to enhance their skills and professional development.

6. Collaboration and Communication

Collaborating with other departments, such as engineering and sales, to ensure smooth project execution and communication.

7. Continuous Improvement

Seeking opportunities to improve processes, optimize production, and reduce costs through continuous improvement initiatives.

8. Vendor Management

Managing relationships with suppliers, negotiating contracts, and ensuring material quality and delivery timelines.

Interview Preparation Tips

1. Research the Company and Position

Thoroughly research the company’s website, LinkedIn page, and industry news to gain insights into their business, culture, and the specific role you’re applying for.

2. Prepare Questions

Prepare thoughtful questions to ask the interviewers. Asking relevant questions demonstrates your interest and engagement in the opportunity.

3. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience that are most relevant to the job description. Use specific examples to illustrate your abilities.

4. Practice Common Interview Questions

Review common interview questions and practice your responses. This will help you feel more confident and articulate during the interview.

5. Dress Professionally and Punctuality

Dress appropriately for the interview and arrive on time. Punctuality and a polished appearance show respect for the interviewer’s time and professionalism.

6. Be Enthusiastic and Positive

Maintain a positive and enthusiastic demeanor throughout the interview. Your attitude can make a significant impression on the interviewers.

7. Follow Up

Send a thank-you note to the interviewers after the interview, reiterating your interest in the position and addressing any additional questions you may have.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Fabricating Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.