Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Fabricator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

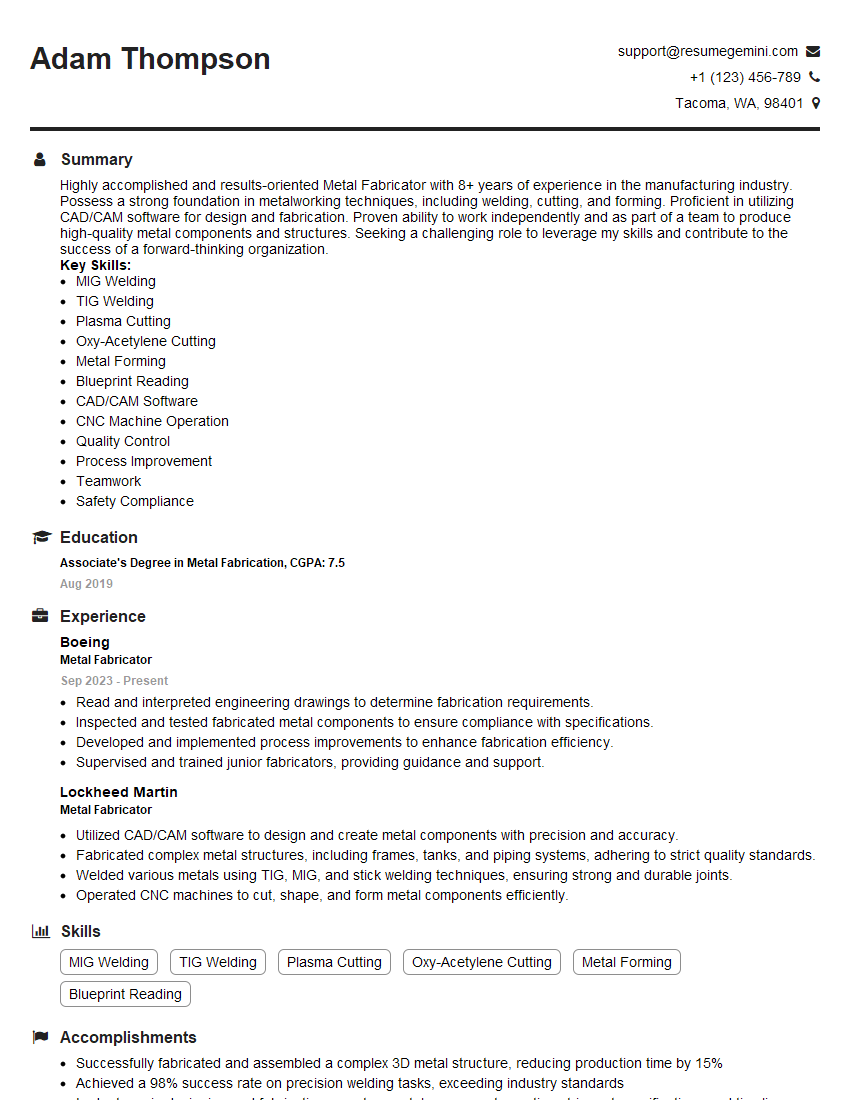

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Fabricator

1. What are the different types of metal fabrication processes?

- Cutting: Various cutting techniques like laser cutting, plasma cutting, and waterjet cutting are used to cut metal into desired shapes.

- Bending: Metal is bent using brakes or press brakes to achieve specific angles or curves.

- Welding: Different welding methods, such as MIG, TIG, and spot welding, are employed to join metal parts together.

- Finishing: Processes like grinding, polishing, and painting enhance the surface quality and protect the metal from corrosion or wear.

2. Explain the principles of MIG welding.

Arc Creation and Filler Material:

- MIG welding uses an electric arc formed between a consumable wire electrode and the metal workpiece.

- The wire electrode continuously feeds into the weld area, acting as both the filler material and the source of the arc.

Shielding Gas:

- An inert gas, usually argon or a mixture of argon and other gases, is used to shield the weld area from atmospheric contamination.

- The shielding gas prevents oxidation and ensures a clean and strong weld.

3. Describe the safety precautions to consider when operating a press brake.

- Wear appropriate PPE: Hardhat, safety glasses, work gloves, and hearing protection.

- Inspect the press brake and tools: Check for any damage or loose parts before use.

- Set up the machine safely: Ensure proper die selection, part placement, and press settings.

- Use proper lifting techniques: Lift heavy materials safely and avoid twisting or straining.

- Clear the work area: Keep the area around the press brake clean and free of obstructions.

4. How do you determine the appropriate cutting speed for a laser cutter?

- Material thickness: Thicker materials require slower cutting speeds to ensure a clean and complete cut.

- Material type: Different metals have varying thermal properties, influencing the optimal cutting speed.

- Laser power: Higher laser power allows for faster cutting, but must be adjusted based on material and thickness.

- Focus and beam quality: Proper lens focusing and beam quality impact the effective cutting speed.

- Gas assist: Assist gases like oxygen or nitrogen can improve cutting efficiency and affect the cutting speed.

5. Explain the role of CAD/CAM in metal fabrication.

- Computer-Aided Design (CAD): Software used to create 3D models of parts and assemblies, facilitating design and engineering.

- Computer-Aided Manufacturing (CAM): Software that converts CAD models into instructions for CNC machines, automating the production process.

- Improved Accuracy: CAD/CAM enables high-precision fabrication by accurately defining part geometries and toolpaths.

- Increased Efficiency: Automated production through CNC machines reduces labor costs and allows for faster turnaround times.

- Reduced Waste: Accurate modeling and CNC cutting minimize material waste and optimize material usage.

6. Describe the factors that influence the selection of a welding process.

- Material thickness and type: Different welding processes are suitable for varying material types and thicknesses.

- Joint geometry: The shape and accessibility of the joint determine the most appropriate welding method.

- Required strength and quality: Different welding techniques offer varying levels of weld strength and quality.

- Production rate: Some welding processes are faster than others, affecting production efficiency.

- Cost and availability: Equipment cost, consumable expenses, and availability of skilled welders influence process selection.

7. How do you ensure the dimensional accuracy of fabricated parts?

- Accurate CAD models: Start with precise 3D models to minimize errors from the design phase.

- Proper machine calibration: Calibrate CNC machines regularly to maintain their accuracy.

- Use of fixtures and jigs: Fixtures hold parts securely during fabrication, ensuring proper alignment and consistency.

- Quality control measures: Implement inspection processes with measuring tools like CMMs or calipers to verify dimensions.

- Continuous improvement: Regularly review and optimize processes to identify and address potential sources of dimensional errors.

8. Describe the different types of metal finishing techniques.

- Mechanical finishing: Grinding, polishing, and brushing are used to smooth and shape metal surfaces.

- Chemical finishing: Acids, bases, or other chemicals are used to alter the surface properties of metal, such as etching or anodizing.

- Electrochemical finishing: Electric current is used to refine surfaces, remove burrs, or apply coatings.

- Thermal finishing: Heat treatments like annealing or tempering can improve the strength or hardness of metal.

- Coating and plating: Metal surfaces can be coated with paint, powder, or other materials to protect or enhance their appearance.

9. Explain the benefits of using CNC machines in metal fabrication.

- Precision and accuracy: CNC machines follow programmed instructions, resulting in high-precision parts with consistent quality.

- Increased efficiency: Automated processes reduce labor requirements and increase production speed.

- Reduced waste: Optimized cutting paths and tool selection minimize material waste.

- Repeatability: CNC machines can produce identical parts repeatedly, ensuring consistent output.

- Complex geometries: CNC machines can create complex and intricate shapes with ease.

10. Describe your experience in project management for metal fabrication projects.

- Planning and scheduling: Developed project plans, timelines, and resource allocation strategies.

- Communication and coordination: Collaborated effectively with design, production, and supply chain teams.

- Quality control: Implemented and maintained quality standards throughout the project lifecycle.

- Cost management: Monitored project expenses and identified opportunities for optimization.

- Risk assessment and mitigation: Proactively identified and addressed potential risks to ensure project success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Fabricators play a vital role in the manufacturing industry, utilizing their expertise in metalworking techniques to create and repair various metal components and structures. Their responsibilities typically include:

1. Fabricating Metal Components

Metal Fabricators are responsible for cutting, shaping, and assembling metal parts and components according to specifications. They use specialized tools and techniques such as welding, soldering, grinding, and bending to create these components.

- Interpreting blueprints and technical drawings

- Selecting appropriate materials and equipment

2. Erection and Installation

In some cases, Metal Fabricators may also be involved in the erection and installation of metal structures. This may involve assembling prefabricated components, welding them together, and ensuring their proper alignment and stability.

- Following safety procedures and using proper protective gear

- Working with other tradespeople to ensure proper integration

3. Repair and Maintenance

Metal Fabricators may also perform repair and maintenance tasks on existing metal structures and components. This may involve welding cracks, repairing damaged sections, and performing general maintenance to ensure the continued functioning of metal parts.

- Inspecting metal structures for damage or wear

- Using appropriate repair techniques and materials

4. Quality Control

Metal Fabricators are responsible for ensuring the quality of their work. This involves adhering to established standards, checking dimensions and tolerances, and ensuring that fabricated components meet the required specifications.

- Using measuring tools and gauges to verify accuracy

- Conducting tests and inspections to ensure quality

Interview Tips

Preparing thoroughly for a job interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Metal Fabricator position:

1. Research the Company and Position

Before the interview, take the time to learn about the company and the specific position you are applying for. This will demonstrate your interest and enthusiasm and show that you have taken the interview seriously. Research the company’s website, read industry news, and check out their social media pages.

- Identify the company’s mission, values, and products/services.

- Understand the job requirements and how your skills align with them.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful answers that highlight your relevant skills and experience. Practice speaking clearly and confidently, and be ready to provide specific examples of your work.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Quantify your accomplishments whenever possible, using numbers and metrics.

3. Demonstrate Your Technical Skills

As a Metal Fabricator, it is crucial to demonstrate your technical skills and knowledge. Be prepared to discuss your experience with different metalworking techniques, such as welding, soldering, and bending. Bring examples of your work or provide references to projects you have completed.

- Explain your understanding of metal properties and metallurgy.

- Discuss safety protocols and industry best practices.

4. Highlight Your Safety Awareness

Working as a Metal Fabricator requires a strong focus on safety. Emphasize your knowledge of safety regulations and your commitment to maintaining a safe work environment. Explain how you prioritize safety in your work and ensure adherence to established procedures.

- Describe your experience using personal protective equipment (PPE).

- Explain how you identify and mitigate potential hazards.

5. Show Your Enthusiasm and Passion

Let the interviewer know that you are genuinely interested in the position and the metal fabrication industry. Convey your passion for working with metals and your desire to contribute to the company’s success. Demonstrate your eagerness to learn and grow within the field.

- Share your motivations for pursuing a career in metal fabrication.

- Express your interest in the company’s projects and how you can contribute.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!