Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Filer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

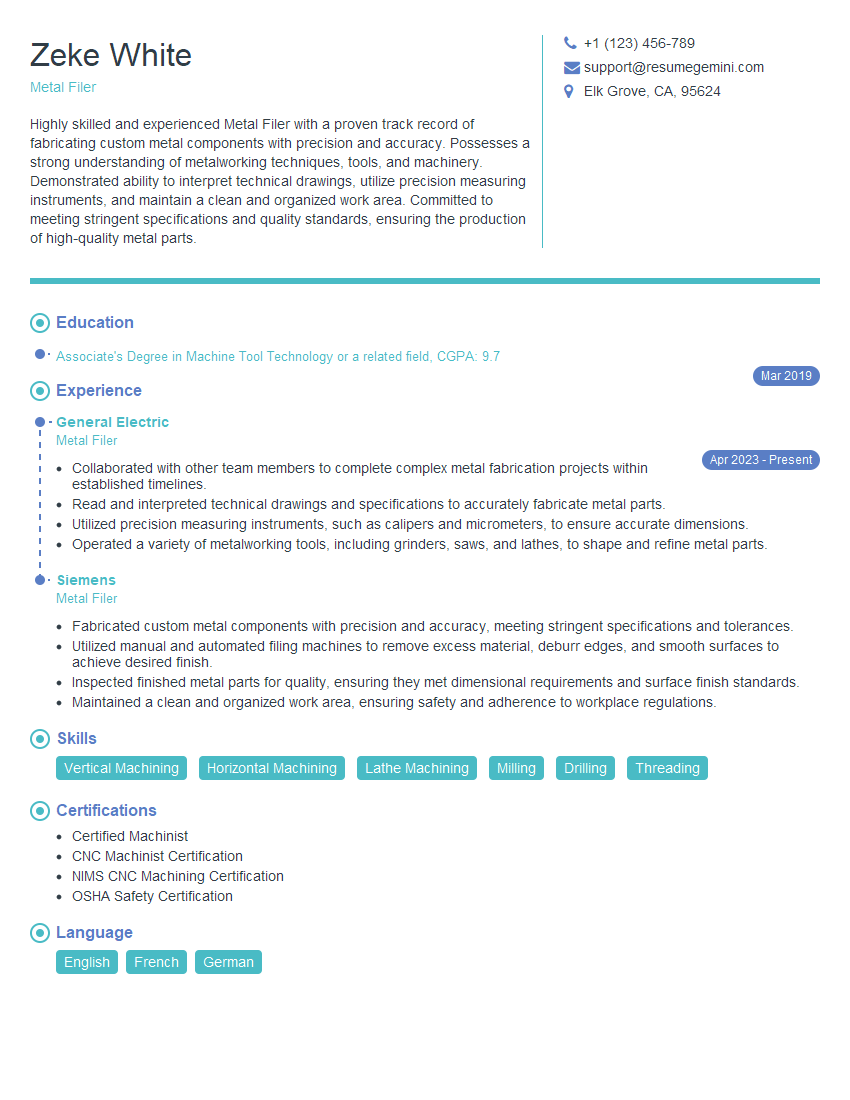

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Filer

1. What are the different types of metal files and their uses?

There are various types of metal files, each with a specific purpose and design. Here are some common types and their uses:

- Flat file: A flat file has a flat surface and is used for general-purpose filing and smoothing surfaces.

- Half-round file: This file has a rounded surface and is used for shaping and contouring.

- Round file: A round file is used for filing holes and curves.

- Triangular file: This file has a triangular cross-section and is used for sharpening and forming sharp angles.

- Rasp file: A rasp file has a coarse surface and is used for removing material quickly.

- Needle file: This file is a small, pointed file used for delicate work.

2. What factors should be considered when selecting a metal file?

Material

- The material of the file should be appropriate for the metal being worked on.

Size

- The size of the file should be suitable for the task at hand.

Shape

- The shape of the file should be chosen based on the desired result.

Coarseness

- The coarseness of the file should be appropriate for the material being worked on.

3. What are the safety precautions that should be taken when using metal files?

There are several safety precautions that should be taken when using metal files to ensure a safe working environment:

- Wear appropriate safety gear, including eye protection, gloves, and a dust mask.

- Secure the metal workpiece firmly in a vise or clamp before filing.

- Use a file with a sharp edge and avoid using dull files.

- File in a well-ventilated area to avoid inhaling metal dust.

- Keep the file clean and free of debris.

- Dispose of metal filings properly.

4. How do you maintain metal files to ensure their longevity?

To ensure the longevity of metal files, proper maintenance is essential. Here are some maintenance tips:

- Clean the files regularly with a brush or compressed air to remove debris.

- Apply a thin layer of oil to the files to prevent rust and extend their lifespan.

- Store the files in a dry place when not in use.

- Avoid dropping or subjecting the files to excessive force.

5. Describe the process of filing a flat surface using a metal file.

Filing a flat surface using a metal file involves several steps:

- Secure the metal workpiece in a vise or clamp.

- Choose a flat file with a sharp edge and appropriate coarseness.

- Hold the file at an angle of 15-20 degrees to the surface and apply downward pressure.

- Move the file back and forth in a smooth, even motion.

- Continue filing until the surface is smooth and even.

6. What techniques can be used to achieve a specific surface finish when filing metal?

To achieve a specific surface finish when filing metal, various techniques can be employed:

- Using different file coarseness: Different file coarseness can create varying surface finishes.

- Varying the filing pressure: Applying more or less pressure can affect the smoothness of the finish.

- Using a draw file: A draw file can be used to create a smooth, polished finish.

- Sanding after filing: Sanding the filed surface can further refine the finish and remove any remaining burrs.

7. What are the common mistakes to avoid when using metal files?

To prevent errors and ensure efficient filing, it is important to avoid common mistakes:

- Using a dull file.

- Filing at an incorrect angle.

- Applying excessive pressure.

- Filing in one direction only.

- Not cleaning the file regularly.

8. What are the different methods for filing internal surfaces and edges?

Filing internal surfaces and edges requires specific approaches:

- Using needle files: Needle files are small and can reach into tight spaces.

- Using a file card: A file card can be used to clean and maintain the shape of files.

- Using a rotary tool: A rotary tool with appropriate attachments can be used to file internal surfaces.

9. How do you select the appropriate file for a particular metalworking task?

Selecting the right file for a specific task is crucial:

- Consider the material: Different metals require specific file types.

- Determine the shape and size: The file should match the shape and size of the surface being worked on.

- Choose the coarseness: The coarseness should be appropriate for the desired finish.

- Inspect the file: Ensure the file is sharp and free of defects.

10. Describe the process of filing a taper using a metal file.

To file a taper using a metal file, follow these steps:

- Secure the metal workpiece in a vise or clamp.

- Choose a flat file with a sharp edge.

- Start filing at one end of the workpiece.

- Gradually increase the angle of the file as you move towards the other end.

- Continue filing until the desired taper is achieved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Filer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Filer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Filer is responsible for shaping and finishing metal parts using a variety of hand and power tools. Their primary focus is to ensure that the metal parts meet the specified dimensions and tolerances.

1. Manual Filing

Using hand files and scrapers, they remove excess metal, smooth surfaces, and create precise edges.

- Select the appropriate file or scraper for the job.

- Secure the metal workpiece in a vise or clamp.

- File or scrape the metal in a controlled manner to achieve the desired shape and finish.

2. Power Filing

Operate power files, such as belt sanders or grinders, to remove large amounts of material or create intricate shapes.

- Choose the correct power file and abrasive belt or grinding wheel.

- Wear appropriate safety gear, such as gloves, eye protection, and a respirator.

- Position the workpiece securely and guide the power file along the surface to remove excess metal.

3. Deburring and Finishing

Remove burrs, sharp edges, or imperfections from metal parts using files, scrapers, or abrasive tools.

- Inspect the workpiece for any burrs or sharp edges.

- Use hand tools or power tools to remove burrs and smooth edges.

- Apply finishing touches, such as polishing or buffing, to improve the appearance and functionality of the part.

4. Inspection and Quality Control

Verify that metal parts meet the specified dimensions, tolerances, and surface finish requirements.

- Use measuring tools, such as calipers, micrometers, and gauges, to verify dimensions.

- Inspect surfaces for any defects, scratches, or imperfections.

- Report any deviations from specifications to the supervisor for further evaluation.

Interview Tips

To prepare for a Metal Filer interview, it is crucial to demonstrate your knowledge of the job responsibilities, technical skills, and safety practices. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and culture. Understand the specific role and responsibilities of a Metal Filer in their organization.

2. Highlight Your Technical Skills

Emphasize your proficiency in manual filing, power filing, deburring, and finishing techniques. Showcase your knowledge of different types of metal files, scrapers, power tools, and abrasives.

3. Demonstrate Accuracy and Attention to Detail

Stress your ability to accurately measure, inspect, and verify metal parts. Provide examples of your adherence to quality standards and your commitment to producing high-quality work.

4. Emphasize Safety Consciousness

Highlight your understanding of safety regulations and your adherence to proper safety procedures. Discuss your experience in wearing personal protective equipment and using tools safely.

5. Prepare Questions for the Interviewer

Prepare thoughtful questions that demonstrate your interest in the position and the company. Inquire about the company’s growth plans, the team environment, or any specific projects that the Metal Filer may be involved in.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Filer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.