Are you gearing up for a career in Metal Finisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Finisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

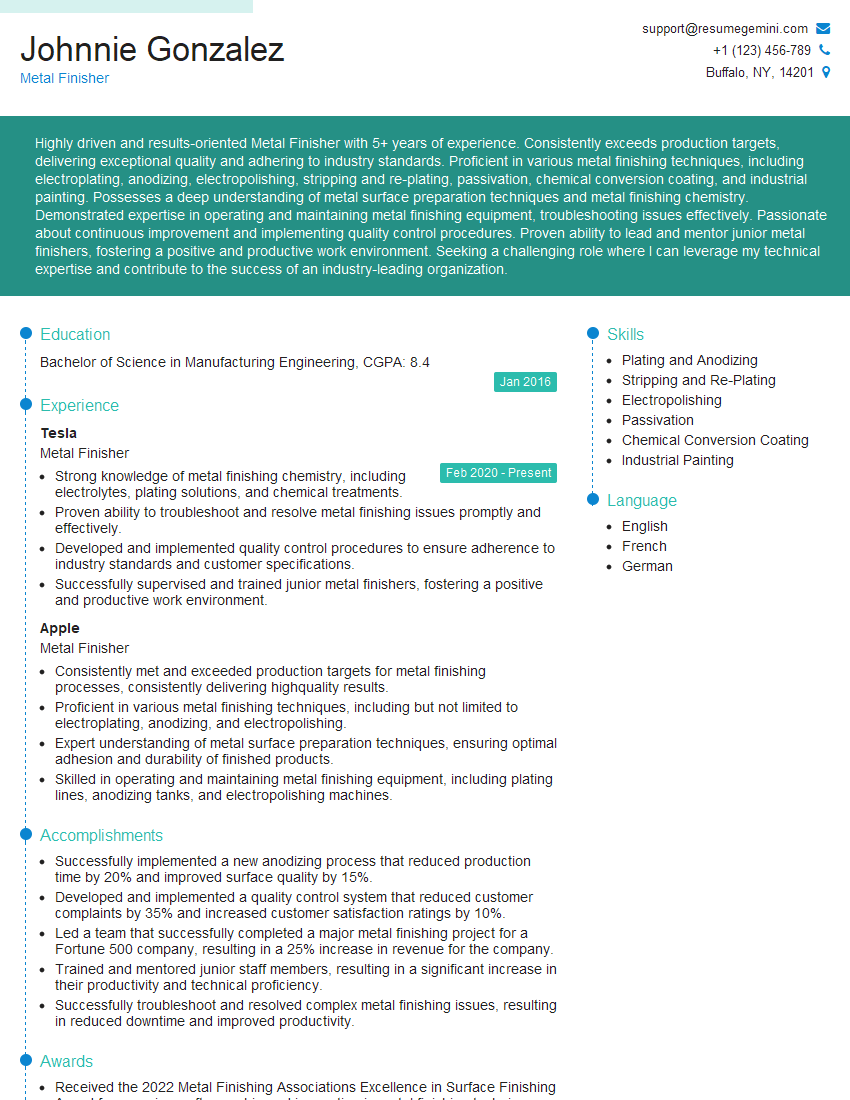

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Finisher

1. What are the different types of metal finishing processes?

There are various types of metal finishing processes, each serving a specific purpose. Some common techniques include:

- Plating: Electroplating, electroless plating, and anodizing are used to deposit a thin layer of metal onto a substrate to enhance corrosion resistance, conductivity, or appearance.

- Coating: Powder coating, painting, and hot-dip galvanizing involve applying a protective or decorative layer to the metal surface.

- Polishing: Mechanical or chemical processes are employed to smooth and brighten the surface, improving its appearance and resistance to wear.

- Cleaning: Chemical or mechanical methods are used to remove contaminants, oils, and oxides from the metal surface, ensuring proper adhesion of subsequent finishes.

- Heat Treatment: Processes like annealing, hardening, and tempering are used to modify the metal’s properties, such as strength, hardness, and ductility.

2. What are the essential safety precautions to consider during metal finishing?

Personal Protective Equipment (PPE)

- Wear appropriate gloves, eye protection, respiratory masks, and protective clothing to prevent contact with hazardous chemicals and fumes.

Chemical Handling

- Handle acids, bases, and other chemicals with care, following proper safety protocols.

- Dispose of chemicals safely and in accordance with environmental regulations.

Ventilation

- Ensure adequate ventilation in the work area to prevent the buildup of toxic fumes and vapors.

Equipment Safety

- Operate equipment properly and follow safety guidelines.

- Maintain equipment regularly to prevent malfunctions and accidents.

3. Describe the process of electropolishing metal.

- The metal workpiece is made the anode in an electrolytic bath containing a suitable electrolyte.

- As a direct current passes through the bath, the metal surface dissolves into the electrolyte.

- Simultaneously, hydrogen is evolved at the cathode, creating a smooth and polished surface on the workpiece.

- The process parameters, such as current density, temperature, and electrolyte composition, are carefully controlled to achieve the desired surface finish.

4. What are the advantages and disadvantages of using chemical etching in metal finishing?

Advantages

- Precise control over the etching depth and pattern.

- Ability to create complex and intricate designs.

- Can be used to create both decorative and functional surfaces.

Disadvantages

- Can be time-consuming and requires careful process control.

- May produce hazardous waste that requires proper disposal.

- Can weaken the metal if excessive etching occurs.

5. Explain how you would prepare a metal surface for powder coating.

- Cleaning: Remove dirt, grease, and other contaminants using chemical cleaners or detergents.

- Surface Preparation: Roughen the surface by blasting or sanding to create a suitable surface for adhesion.

- Pre-Treatment: Apply a chemical conversion coating or primer to enhance the bond between the metal and the powder coating.

6. What factors affect the thickness of an electroplated coating?

- Current density: Higher current density results in thicker coatings.

- Electrolyte concentration: Higher electrolyte concentration leads to thicker coatings.

- Temperature: Higher temperatures generally result in thicker coatings.

- Plating time: Longer plating times produce thicker coatings.

- Agitation: Agitation of the electrolyte helps ensure uniform coating thickness.

7. Describe the role of anodes in electroplating processes.

- Anodes provide the metal ions that are deposited on the cathode (workpiece).

- The anode material should be the same metal as the coating being deposited.

- Anodes can be soluble, continuously dissolving into the electrolyte, or insoluble, requiring periodic replacement.

- The shape and size of the anode influence the current distribution and coating uniformity.

8. Explain how you would troubleshoot a problem with poor adhesion of a metal coating.

- Check surface preparation: Ensure the metal surface was properly cleaned and prepared before coating.

- Inspect coating process: Verify that the coating parameters, such as current density, temperature, and electrolyte composition, are correct.

- Examine the coating: Look for signs of poor adhesion, such as peeling or flaking.

- Test the coating: Conduct adhesion tests to quantify the bond strength between the coating and the substrate.

- Identify and address the root cause: Based on the observations and tests, determine the underlying cause of the adhesion problem and implement corrective measures.

9. What is the difference between mechanical and chemical polishing?

Mechanical Polishing

- Uses abrasive materials, such as sandpaper, grinding wheels, or polishing compounds.

- Removes material from the surface to achieve a smooth finish.

- Can generate heat, which may affect the metal’s properties.

Chemical Polishing

- Uses chemical solutions to dissolve the metal surface.

- Creates a smooth and reflective finish without removing significant material.

- Produces less heat and is suitable for delicate or thin metal parts.

10. How do you ensure the quality of metal finishes?

- Visual Inspection: Examine the finish for defects, such as scratches, pits, or unevenness.

- Thickness Measurement: Use non-destructive testing methods to measure the thickness of the coating.

- Adhesion Testing: Conduct tests to assess the bond strength between the coating and the substrate.

- Salt Spray Testing: Expose the finished metal to a salt spray environment to evaluate its corrosion resistance.

- Documentation: Maintain records of the finishing process, including parameters and quality control results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal finishers are responsible for the final stages of metal products: preparing the surface of the metal, coating it, and performing the final quality checks. Some specialized metal finishers work only with particular metals, such as stainless steel, or products, such as medical devices.

1. Preparation

Metal finishers prepare the surface of the metal for further processing. This may include cleaning, polishing, and smoothing the surface. They may also apply a coating to the metal to protect it from corrosion or to improve its appearance.

- Clean and degrease metal surfaces

- Polish and buff metal surfaces

- Apply coatings to metal surfaces

2. Coating

Metal finishers apply a variety of coatings to metal surfaces, including paints, primers, and sealants. The type of coating used depends on the desired appearance, protection, and other factors.

- Apply paints, primers, and sealants

- Use spray guns, brushes, and other tools

- Ensure proper thickness and coverage

3. Quality Control

Metal finishers inspect the finished product to ensure that it meets the required quality standards. This may include checking the appearance, thickness, and durability of the coating.

- Inspect finished metal products

- Check for defects, such as scratches, dents, and discoloration

- Measure the thickness and durability of coatings

4. Maintenance

Metal finishers maintain the equipment and tools used in the finishing process. This may include cleaning, repairing, and calibrating equipment.

- Clean, repair, and calibrate equipment

- Maintain a safe and clean work environment

- Follow safety guidelines

Interview Tips

To ace the interview for a metal finisher position, follow these general interview preparation tips:

1. Research the Company and Position

Before your interview, research the company and the position you are applying for. This will help you better understand the company’s culture, values, and what they are looking for in a metal finisher. You can find information about the company on their website, social media pages, and industry publications.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Talk to people in your network who work for the company.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Be specific and provide examples.

- Practice your answers out loud.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight the skills and experience that you have that are relevant to the metal finisher position. For example, if you have experience in surface preparation, coating application, or quality control, be sure to mention this in your interview. You can also highlight any relevant certifications or training that you have.

- Review the job description and identify the required skills and experience.

- Match your skills and experience to the job requirements.

- Quantify your accomplishments whenever possible.

4. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are serious about working for the company. Some good questions to ask include:

- “What are the biggest challenges facing the metal finishing industry right now?”

- “What is the company’s culture like?”

- “What are the opportunities for advancement within the company?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!