Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Hardener interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Hardener so you can tailor your answers to impress potential employers.

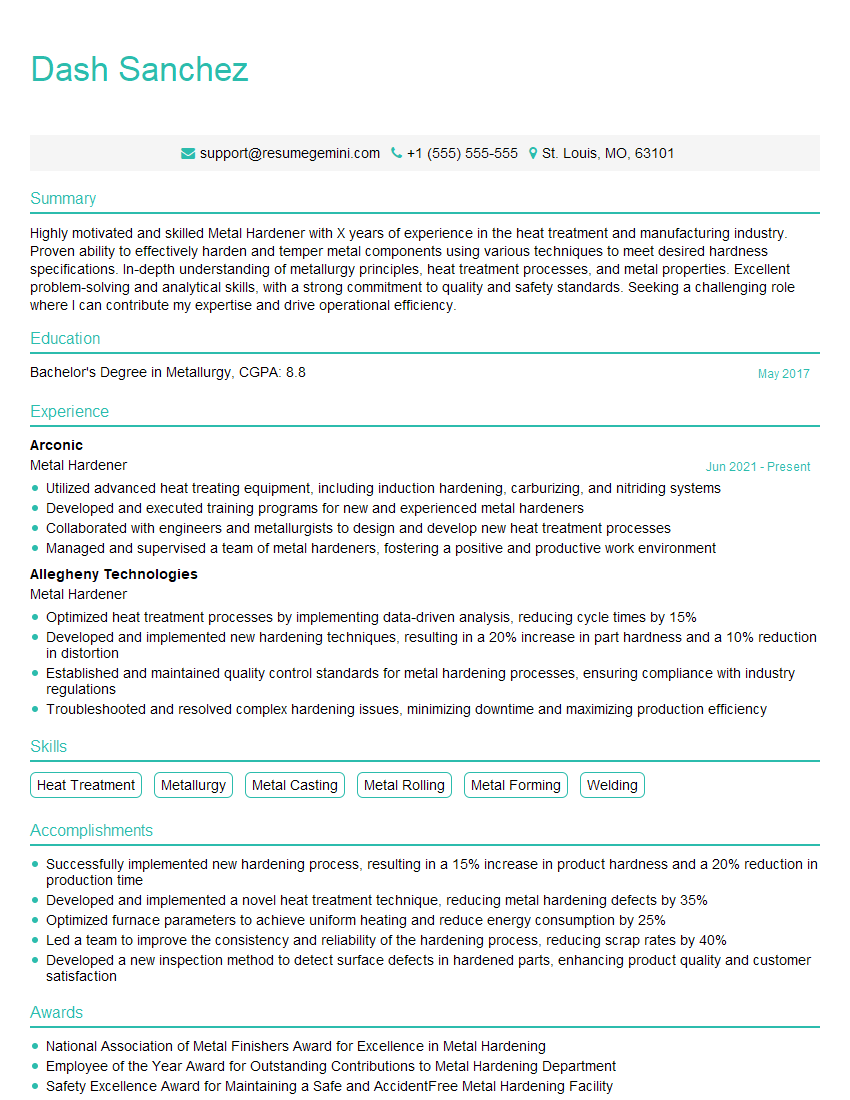

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Hardener

1. How do you determine the correct hardness level for a specific type of metal?

- Hardness is determined based on the application and performance requirements of the metal.

- Factors such as wear resistance, strength, toughness, and corrosion resistance are considered.

- Hardness is measured using standardized tests like Rockwell, Vickers, or Brinell.

2. Describe the process of hardening a metal using heat treatment.

Quenching

- Heating the metal to a specific temperature called the austenitizing temperature.

- Rapidly cooling the metal by immersing it in a quenching medium like water, oil, or polymer.

Tempering

- Further heating the quenched metal to a lower temperature and holding it there for a specific duration.

- Slow cooling the metal to achieve the desired hardness and microstructure.

3. What are the different types of hardening processes and their advantages and disadvantages?

- Case hardening: Hardening only the surface of the metal, leaving the core soft and ductile.

- Through hardening: Hardening the metal throughout its cross-section.

- Flame hardening: Localized hardening using a focused flame.

4. How do you control the depth of hardening in a metal?

- By varying the temperature and duration of the heat treatment process.

- Using different quenching media to control the cooling rate.

- Employing induction hardening or carburizing techniques to achieve specific hardness levels.

5. What are the common defects that can occur during metal hardening and how do you prevent them?

- Quenching cracks: Prevention includes proper heating, controlled cooling, and preheating before quenching.

- Warpage: Prevention includes uniform heating, supporting the metal during cooling, and using fixtures.

- Scaling: Prevention includes controlled atmosphere, protective coatings, and proper cleaning before heat treatment.

6. How do you test the hardness of a metal after hardening?

- Rockwell test: Measuring the depth of indentation made by a diamond or tungsten carbide indenter.

- Vickers test: Measuring the diagonal length of a square indentation made by a diamond indenter.

- Brinell test: Measuring the diameter of an indentation made by a hardened steel ball.

7. What are the factors that affect the hardness of a metal?

- Alloy composition: Different elements and their proportions influence the hardness.

- Heat treatment: The temperature, cooling rate, and time of heat treatment determine the microstructure and hardness.

- Cold working: Mechanical deformation through processes like rolling or forging can increase hardness.

8. How do you calculate the hardness of a metal from its tensile strength?

- Hardness (HV) ≈ Tensile strength (MPa) / 3

- This approximation is applicable for certain types of metals and may vary depending on the material.

9. What are the applications of hardened metals?

- Cutting tools: Drills, milling cutters, and other tools used in machining.

- Wear-resistant components: Gears, bearings, and other parts subjected to friction and abrasion.

- Armour and military equipment: Protection against projectiles, weapons, and impact.

10. Describe your experience in working with different types of metals and hardening processes.

- Briefly mention the specific metals and processes you have experience with.

- Highlight any unique challenges or successful projects involving metal hardening.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Hardener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Hardener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Hardener is responsible for enhancing the hardness and durability of metal components. Their primary duties include:

1. Heat Treatment Operations

Performing heat treatment processes such as hardening, tempering and annealing to alter the physical properties of metals.

- Operating furnaces and quenching tanks to achieve desired temperature and cooling rates.

- Monitoring temperature and controlling process parameters to ensure optimal results.

2. Quality Control

Conduct testing and inspections to ensure the quality and hardness of treated components.

- Using specialized equipment such as Rockwell hardness testers and microscopy for analysis.

- Maintaining records of test results and identifying areas for improvement.

3. Equipment Maintenance

Ensuring proper functioning of heat treatment equipment and machinery.

- Performing preventive maintenance and repairs as needed.

- Calibrating and maintaining temperature control systems for accurate results.

4. Safety Compliance

Adhering to safety regulations and handling hazardous materials responsibly.

- Wearing appropriate personal protective equipment (PPE).

- Following established safety protocols and procedures.

Interview Tips

To ace an interview for a Metal Hardener position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and reputation within the metalworking industry.

- Review their website, social media presence, and industry news.

- Demonstrate your understanding of current trends and technologies in metal hardening.

2. Highlight Your Technical Expertise

Emphasize your proficiency in heat treatment techniques, quality control methods, and equipment maintenance.

- Quantify your experience and provide specific examples of successful projects.

- Discuss your understanding of different metal alloys and their hardening properties.

3. Showcase Your Attention to Detail

Stress your meticulousness and precision in conducting tests, maintaining equipment, and ensuring quality.

- Share examples of your ability to identify and resolve problems in a timely manner.

- Describe your systematic approach to data collection and analysis.

4. Communicate Effectively

Demonstrate your ability to clearly articulate technical information and collaborate with others.

- Be prepared to discuss your previous work experience and how it aligns with the job requirements.

- Show your willingness to share knowledge and contribute to team efforts.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Hardener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!