Are you gearing up for a career in Metal Lather? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Metal Lather and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

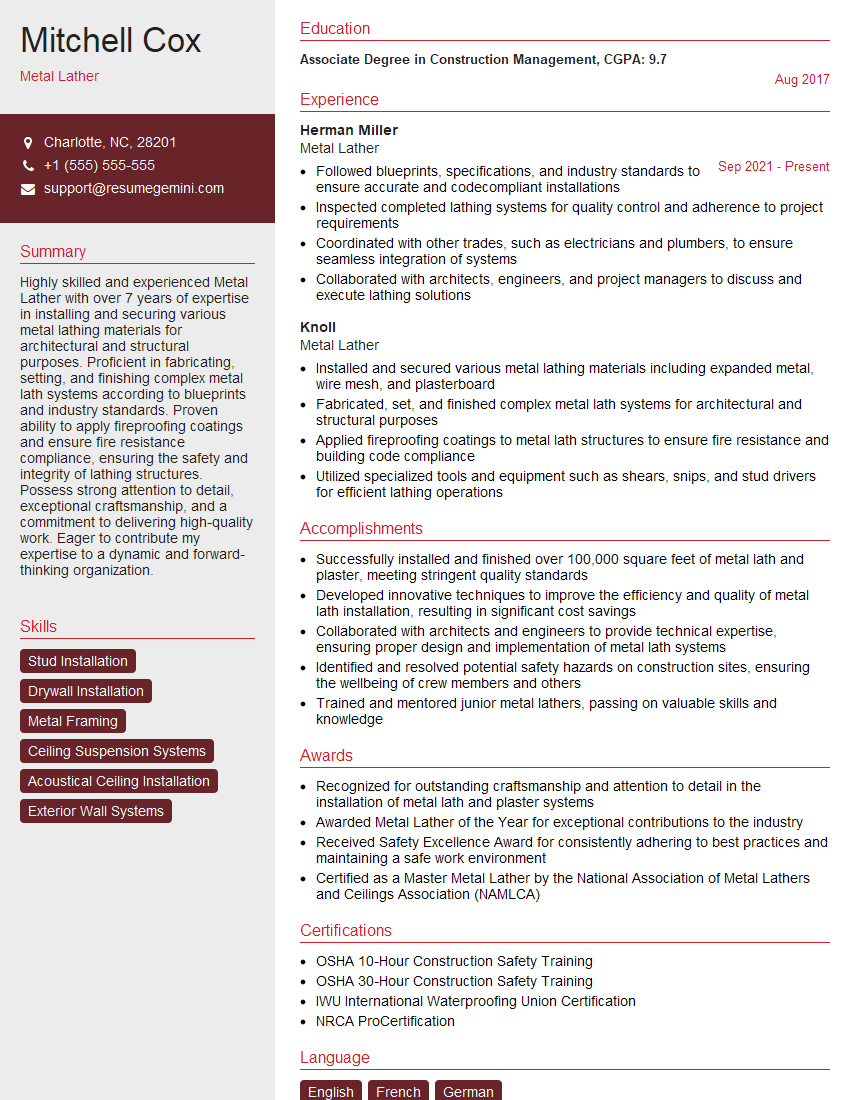

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Lather

1. What are the different types of metal lathing materials available?

There are various types of metal lathing materials available, including:

- Expanded metal lath: Made from sheets of metal that are cut and expanded into a diamond or hexagonal pattern.

- Ribbed metal lath: Features parallel ribs or corrugations that enhance strength and rigidity.

- Welded wire lath: Consists of welded wire mesh that provides a strong and stable base for plaster or stucco.

- Perforated metal lath: Has holes or perforations throughout the material, allowing for ventilation and drainage.

- Self-furring metal lath: Designed with built-in furring strips or spacers that eliminate the need for separate furring.

2. What are the key factors to consider when selecting a metal lathing material?

Material Strength

- Consider the load-bearing requirements of the application.

- Select materials that meet the specified strength and durability standards.

Corrosion Resistance

- Choose materials that are resistant to rust and corrosion in the given environment.

- Consider the presence of moisture, chemicals, or other corrosive elements.

Fire Resistance

- Select materials that have appropriate fire-resistance ratings for the application.

- Consider the potential fire hazards and building codes.

Cost and Availability

- Consider the project budget and the availability of different materials.

- Research and compare costs from multiple suppliers.

3. What are the proper techniques for installing metal lath on different types of surfaces?

Installing metal lath involves varying techniques depending on the surface type:

- On wood framing: Fasten the lath to the studs using galvanized nails or staples.

- On concrete or masonry: Secure the lath with self-drilling screws or adhesive anchors.

- On curved surfaces: Use flexible or perforated lath and bend it to fit the contours.

- For exterior applications: Apply weather-resistant sealants or membranes to protect against moisture penetration.

4. How do you ensure the proper alignment and spacing of metal lath during installation?

To ensure proper alignment and spacing:

- Use a level and chalk line to mark reference points.

- Install furring strips or spacers to maintain consistent spacing.

- Overlapping edges of lath sheets should be properly fastened and secured.

- Check alignment and spacing regularly during and after installation.

5. What are the common defects or problems encountered during metal lathing installation and how do you address them?

- Poor adhesion: Ensure proper surface preparation, apply adhesive anchors or primers, and use appropriate fasteners.

- Buckling or warping: Address temperature fluctuations, use flexible lath on curved surfaces, and secure the lath adequately.

- Corrosion: Select corrosion-resistant materials, apply protective coatings, and avoid exposure to moisture.

- Misalignment or spacing issues: Re-check alignment using a level, adjust furring strips, and overlap lath sheets correctly.

- Loose or missing fasteners: Inspect fasteners regularly, retighten or replace loose ones, and ensure they are properly sized and spaced.

6. What safety precautions should be observed while working with metal lathing materials?

- Wear appropriate safety gear, including gloves, safety glasses, and respirators.

- Handle metal sheets carefully to avoid cuts or abrasions.

- Ensure proper ventilation and avoid inhaling dust or fumes.

- Be aware of sharp edges and wear appropriate clothing to prevent puncture wounds.

- Follow proper lifting techniques and avoid overexertion.

7. How do you measure and calculate the amount of metal lath required for a project?

To calculate the amount of metal lath needed:

- Measure the area to be covered, including any overlaps or cutouts.

- Consider the width and length of the lath sheets being used.

- Allow for a reasonable amount of overlap at the joints.

- Calculate the total square footage required by multiplying the area by the number of layers needed.

- Add a buffer percentage for waste and unforeseen circumstances.

8. What is the purpose of using corner beads and accessories in metal lathing?

- Corner beads: Protect and reinforce corners from damage and provide a straight edge for plaster or stucco.

- Lath clips: Hold the lath in place and provide a consistent spacing from the framing.

- Lath channels: Create a furring system for curved or irregular surfaces, allowing the lath to be securely attached.

- Expansion joints: Allow for movement due to thermal expansion or contraction, preventing cracking.

9. How do you prepare and apply plaster or stucco over metal lath?

To prepare and apply plaster or stucco over metal lath:

- Ensure the lath is securely installed and free from loose debris.

- Apply a bonding agent or scratch coat to enhance adhesion.

- Mix and apply the plaster or stucco according to the manufacturer’s instructions.

- Use a trowel to spread and smooth the material evenly.

- Allow the material to set and cure properly before further finishing.

10. What are the different types of finishes that can be applied to metal lath and plaster or stucco surfaces?

- Smooth trowel finish: A smooth, flat surface with minimal texture.

- Textured trowel finish: A rougher surface with added texture or patterns using a trowel or sponge.

- Float finish: A smooth, even finish created by floating the surface with a trowel.

- Venetian plaster finish: A decorative, polished finish with a marble-like appearance.

- Stucco finish: A durable, textured finish applied to exterior walls.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Lather.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Lather‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Lathers are responsible for installing and maintaining metal frameworks and supporting structures for ceilings, walls, and partitions in buildings.

1. Installation

• Install metal lath and accessories to provide a base for plaster or other finishes on ceilings, walls, and partitions.

- Read blueprints and specifications to determine the location and type of metal lath to be installed.

- Cut and bend metal lath to fit the desired shape and size.

- Attach metal lath to framing using nails, screws, or other fasteners.

2. Maintenance and Repair

• Inspect and repair damaged metal lath and supporting structures.

- Identify damaged areas and determine the cause of damage.

- Remove damaged metal lath and replace it with new material.

- Repair or replace supporting structures as needed.

3. Safety

• Follow safety regulations and wear appropriate protective gear.

- Wear hard hats, safety glasses, and gloves while working.

- Use proper lifting techniques and avoid working at heights without proper safety equipment.

- Maintain a clean and organized work area.

4. Communication

• Communicate effectively with other construction workers and supervisors.

- Discuss project details and coordinate work schedules with other trades.

- Report any problems or concerns to supervisors promptly.

- Provide feedback and suggestions to improve work processes.

Interview Tips

To ace the interview for a Metal Lather position, it is essential to prepare thoroughly. Here are some tips to help you make a strong impression:

1. Research the Company and the Position

• Visit the company’s website to learn about their history, values, and current projects.

• Read the job description carefully and identify the key skills and experience required.

2. Practice Your Answers

• Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”.

• Rehearse your answers to demonstrate your knowledge, skills, and enthusiasm for the role.

3. Highlight Your Experience and Skills

• Emphasize your experience in metal lathing, including the types of projects you have worked on and the techniques you are proficient in.

• Showcase your skills in blueprint reading, metal cutting and bending, and installation techniques.

4. Show Your Passion

• Express your passion for metal lathing and explain why you enjoy this type of work.

• Share examples of projects you have completed that you are particularly proud of.

5. Ask Questions

• Prepare questions to ask the interviewer, such as the company’s safety protocols and opportunities for professional development.

• Asking questions shows your interest in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Lather interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!