Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Metal Melter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

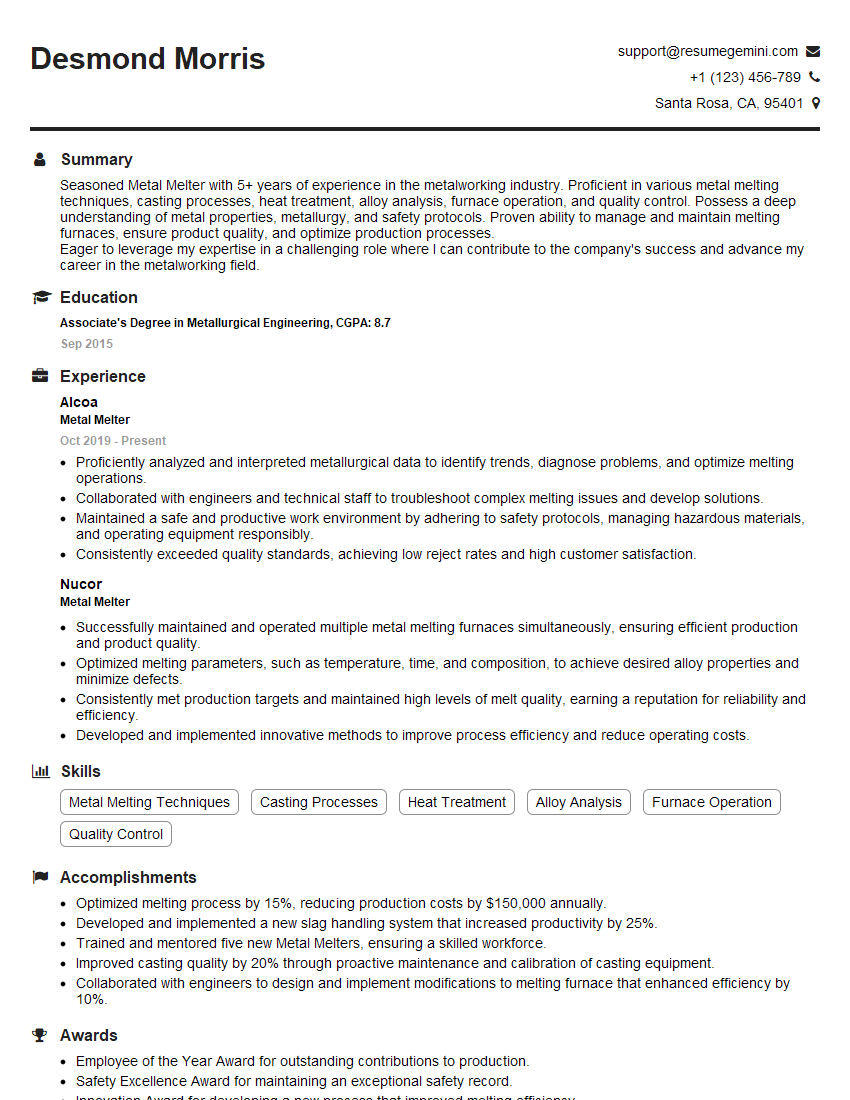

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Melter

1. Describe the process involved in melting metals in an electric arc furnace.

- Prepare the furnace by lining it with refractory materials and connecting it to the power supply.

- Load the furnace with scrap metal or other materials.

- Ignite the electric arc between the electrodes and the metal.

- Maintain the arc and control the temperature to melt the metal.

- Refine the molten metal by adding alloying elements or removing impurities.

- Tap the molten metal from the furnace and cast it into desired shapes.

2. What are the different types of electric arc furnaces and their applications?

Direct Current Furnaces (DC Furnaces)

- Used for melting high-carbon steels and alloys.

- Provide precise arc control and low electrode consumption.

Alternating Current Furnaces (AC Furnaces)

- Used for melting a wide range of metals, including aluminum, copper, and stainless steel.

- More energy-efficient than DC furnaces.

Ultra-High Power (UHP) Furnaces

- Used for high-speed melting of scrap metal.

- Provide improved productivity and reduced energy consumption.

3. What are the critical parameters to consider when operating an electric arc furnace?

- Arc voltage and current

- Furnace temperature

- Metal composition

- Oxygen content in the furnace atmosphere

- Electrode consumption

4. Explain the safety precautions to be observed when working with an electric arc furnace.

- Wear proper protective clothing, including fire-resistant garments and face shields.

- Maintain a safe distance from the furnace and avoid exposure to high temperatures.

- Be aware of potential hazards, such as electrical shock, molten metal spills, and explosions.

- Follow established safety protocols and procedures.

5. Describe the different methods used to charge an electric arc furnace.

- Top charging: Materials are loaded into the furnace from above.

- Side charging: Materials are loaded into the furnace through openings on the side.

- Bottom charging: Materials are loaded into the furnace through openings on the bottom.

6. Explain the role of fluxes in the electric arc furnace process.

- Remove impurities and slag from the molten metal.

- Protect the molten metal from oxidation.

- Improve the electrical conductivity of the molten metal.

7. Describe the different methods used to tap molten metal from an electric arc furnace.

- Lip pouring: Molten metal is poured over the lip of the furnace into a ladle.

- Bottom tapping: Molten metal is drained from the furnace through a taphole at the bottom.

8. What are the common defects that can occur in castings produced from electric arc furnaces and how can they be prevented?

- Shrinkage cavities: Caused by solidification shrinkage of the molten metal. Can be prevented by using proper mold design and gating systems.

- Gas porosity: Caused by dissolved gases in the molten metal. Can be prevented by degassing the metal before casting.

- Cold shuts: Caused by premature solidification of the molten metal, creating weak areas in the casting. Can be prevented by maintaining proper pouring temperature and mold temperature.

9. Describe the steps involved in troubleshooting common problems encountered in electric arc furnace operations.

- Identify the problem and its symptoms.

- Gather information about the operating conditions.

- Analyze the data and identify potential causes.

- Develop and implement corrective actions.

- Monitor the results and make adjustments as needed.

10. How do you maintain and calibrate the equipment used in electric arc furnace operations?

- Regularly inspect and clean equipment.

- Calibrate instruments according to manufacturer’s specifications.

- Perform preventive maintenance to identify and address potential issues.

- Keep a detailed log of maintenance and calibration activities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Melter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Melter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Melter is responsible for the safe and efficient melting of metals, such as aluminum, steel, and iron, in furnaces to create molten metal for casting or other processes.

1. Furnace Operation

Load and unload furnaces with metal scrap, alloys, and fluxing agents.

- Ignite and maintain furnace temperatures.

- Monitor and adjust furnace controls to achieve desired metal properties.

2. Molten Metal Handling

Operate equipment to tap and pour molten metal from furnaces into molds or holding vessels.

- Control the flow of molten metal to prevent spills or accidents.

- Perform metal sampling and analysis to ensure quality.

3. Safety and Maintenance

Follow safety regulations and protocols related to furnace operation and molten metal handling.

- Inspect and maintain furnaces and related equipment.

- Clean up work areas and dispose of hazardous materials properly.

4. Production Management

Meet production quotas and ensure efficiency in the melting process.

- Train and supervise junior melters.

- Coordinate with other production personnel to optimize operations.

Interview Tips

Preparing thoroughly for an interview as a Metal Melter can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company’s history, products or services, and industry standing. Understand the specific responsibilities of the Metal Melter role and how it aligns with your skills and experience.

- Visit the company website and study their corporate profile.

- Read industry news and articles to stay informed about current trends.

2. Highlight Relevant Experience and Skills

Tailor your resume and interview responses to emphasize your qualifications for the Metal Melter position. Quantify your accomplishments whenever possible.

- Describe your experience in operating and maintaining furnaces.

- Share examples of your ability to handle molten metal safely and efficiently.

- Highlight your knowledge of metal properties and quality control.

3. Prepare for Technical Questions

Metal Melter interviews often include technical questions to assess your understanding of industry practices and safety protocols.

- Review basic principles of metallurgy, including melting points, alloying, and heat treatment.

- Practice describing the steps involved in the melting process, from furnace loading to molten metal handling.

- Be familiar with common furnace types and their applications.

4. Practice Communication and Interpersonal Skills

Effective communication and interpersonal skills are crucial for a Metal Melter. You may need to interact with supervisors, team members, and customers.

- Prepare to clearly and concisely explain your understanding of the job responsibilities.

- Practice describing situations where you successfully resolved technical or safety issues.

- Demonstrate your willingness to work in a team environment.

5. Be Enthusiastic and Professional

Your enthusiasm for the Metal Melter profession and your eagerness to contribute to the company’s success will make a positive impression.

- Express your passion for metallurgy and the challenges of the job.

- Show that you are committed to safety and quality.

- Dress professionally and arrive on time for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Melter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!