Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Milling Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Milling Machine Operator so you can tailor your answers to impress potential employers.

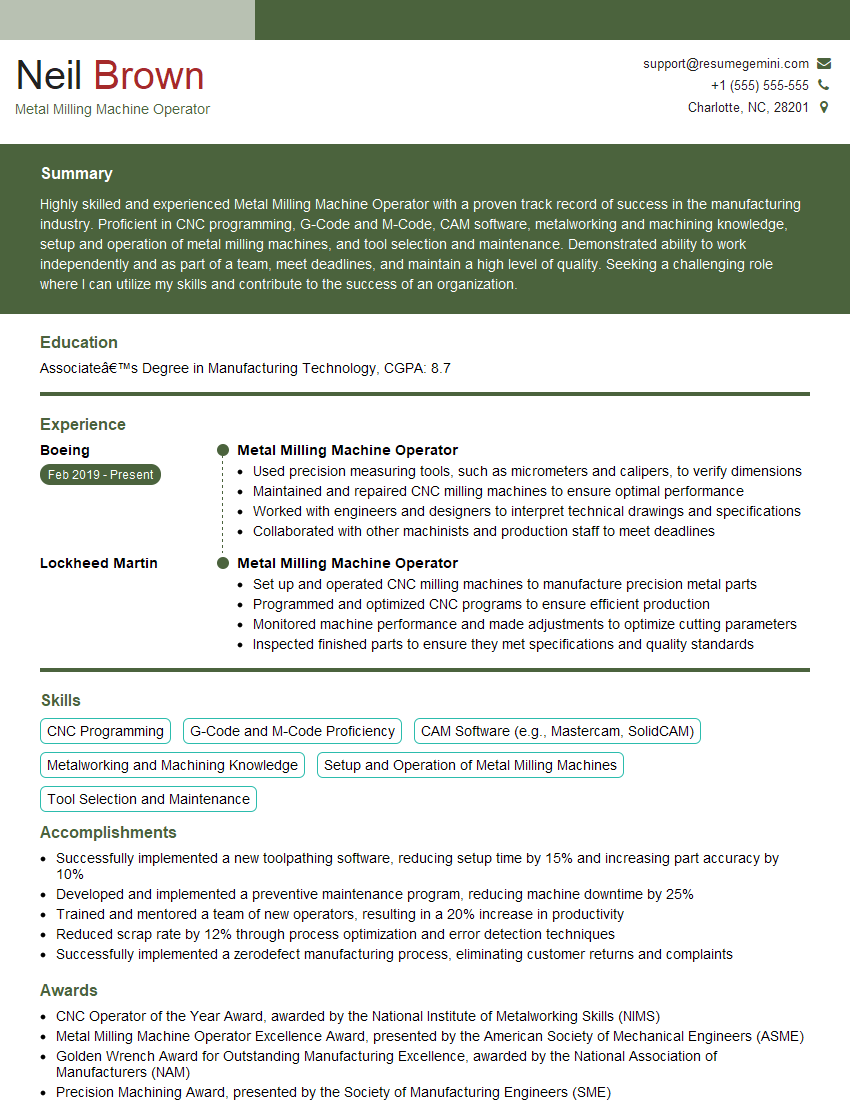

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Milling Machine Operator

1. What types of metal milling machines have you operated in the past?

In my previous role, I have operated various types of metal milling machines, including:

- Vertical milling machines

- Horizontal milling machines

- CNC milling machines

2. What is the difference between climb milling and conventional milling?

Climb Milling

- Definition: The cutting tool moves in the same direction as the workpiece rotation.

- Advantages: Reduced cutting forces, improved surface finish, increased tool life.

Conventional Milling

- Definition: The cutting tool moves in the opposite direction of the workpiece rotation.

- Advantages: Simpler setup, less tool deflection.

3. How do you calculate the feed rate for a milling operation?

The feed rate is calculated using the formula: Feed rate = (Cutting speed) x (Number of teeth on the cutter) / (Number of flutes on the cutter).

4. What are the different types of milling cutters and their applications?

- End mills: General-purpose milling for creating pockets, slots, and profiles.

- Face mills: Milling flat surfaces and removing large amounts of material.

- Ball mills: Creating contoured surfaces and profiles.

- Shell mills: High-volume material removal and heavy-duty applications.

5. What is the purpose of a coolant in a milling operation?

- Cooling the workpiece and cutting tool

- Lubricating the cutting tool and workpiece

- Removing chips from the cutting zone

6. How do you set up and align a workpiece on a milling machine?

- Use clamps or a vise to secure the workpiece

- Align the workpiece using parallels, angle plates, or other fixtures

- Use a dial indicator or other measuring tool to ensure alignment

7. What are the safety precautions to be taken when operating a milling machine?

- Wear appropriate safety gear (e.g., safety glasses, gloves)

- Keep hands and clothing away from moving parts

- Secure the workpiece properly

- Be aware of potential hazards (e.g., sharp edges, flying chips)

8. What types of materials can be milled?

- Metals (e.g., steel, aluminum, brass)

- Plastics

- Wood

- Composites

9. How do you troubleshoot common problems encountered in milling operations?

- Chattering: Check for loose fixtures, dull cutters, or excessive feed rates.

- Poor surface finish: Use sharper cutters, adjust feed rates, or use different coolant.

- Tool breakage: Inspect for damaged cutters, excessive cutting forces, or improper setup.

10. What are the latest advancements in metal milling technology?

- Computer Numerical Control (CNC) milling

- Automated tool changers

- High-speed machining

- 3D milling

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Milling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Milling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Milling Machine Operator is responsible for operating and maintaining metal milling machines to create precise metal parts and components. The primary duties involve:

1. Machine Operation

Setting up and operating metal milling machines according to specifications and blueprints.

- Selecting and installing appropriate cutting tools and workholding devices.

- Loading, positioning, and securing metal stock onto the machine table.

- Controlling machine settings, such as speed, feed, and depth of cut.

- Monitoring machine operation for potential issues or errors.

2. Quality Control

Inspecting finished parts to ensure they meet dimensional accuracy, surface finish, and other quality standards.

- Using precision measuring instruments, such as calipers, micrometers, and height gauges.

- Comparing measurements to specifications and identifying any deviations.

- Making necessary adjustments to the machine or process to correct any errors.

3. Maintenance and Repairs

Performing basic maintenance and repairs on metal milling machines to ensure optimal performance.

- Lubricating moving parts and checking for wear and tear.

- Replacing worn or damaged parts, such as cutting tools and coolant pumps.

- Cleaning and maintaining the machine to prevent contamination or corrosion.

4. Troubleshooting

Diagnosing and resolving issues that may arise during machine operation.

- Identifying potential causes of problems, such as tool breakage, incorrect settings, or material defects.

- Taking corrective actions, such as adjusting machine parameters, replacing cutting tools, or contacting maintenance personnel.

- Documenting any issues or repairs performed for future reference.

Interview Tips

To prepare for an interview for a Metal Milling Machine Operator position, consider the following tips:

1. Research the Company and Position

Gather information about the company, its products or services, and the specific role you’re applying for. This will help you understand the company’s culture, goals, and expectations for the position.

- Visit the company’s website and social media pages.

- Read industry publications and news articles to stay up-to-date on industry trends.

2. Practice Common Interview Questions

Prepare responses to common interview questions that are relevant to the role. Practice answering these questions out loud to improve your delivery and confidence.

- Tell me about your experience operating metal milling machines.

- Describe your quality control process for ensuring the accuracy of milled parts.

- How do you troubleshoot and resolve common issues that arise during machine operation?

- What is your experience with maintenance and repair of metal milling machines?

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are most relevant to the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Use specific examples from your previous work experience to illustrate your abilities.

- Be prepared to discuss your proficiency with different types of metal milling machines and cutting tools.

4. Be Prepared to Discuss Safety

Safety is paramount in metalworking environments. Demonstrate your understanding of safety protocols and your commitment to maintaining a safe work area.

- Discuss your experience with following safety regulations and using personal protective equipment.

- Explain how you would handle potential hazards in the workplace, such as rotating machinery or sharp objects.

5. Show Your Enthusiasm for the Role

Express your interest in the position and the company. Explain why you’re passionate about metalworking and how your skills and experience would make you a valuable asset to the team.

- Be enthusiastic and positive throughout the interview.

- Ask thoughtful questions to show your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Milling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!