Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Metal Model Builder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Metal Model Builder so you can tailor your answers to impress potential employers.

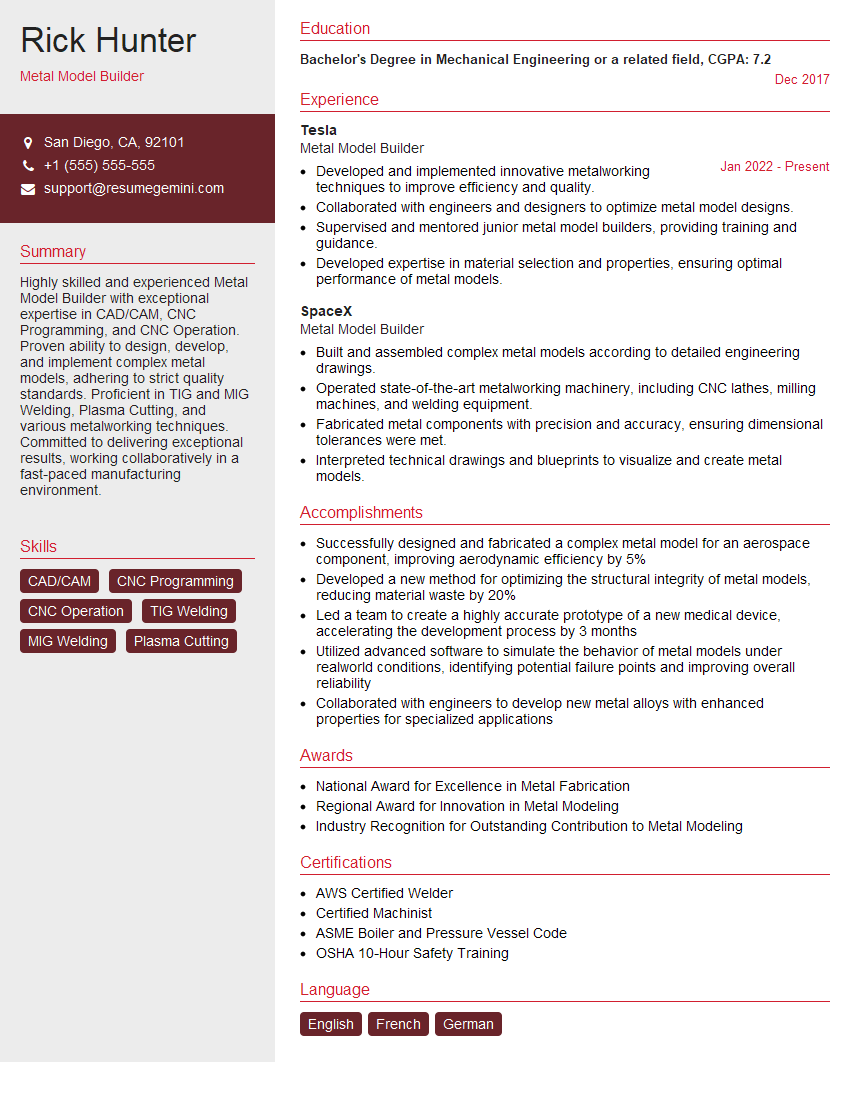

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Model Builder

1. What techniques do you use to ensure the accuracy of your metal model building?

- Using detailed blueprints or technical drawings to ensure precise measurements and dimensions.

- Employing precision tools and equipment, such as calipers, micrometers, and layout tools, for accurate cutting and shaping.

- Referencing original models or historical documents to ensure authenticity and attention to detail.

- Collaborating with engineers or other subject matter experts to verify technical specifications and ensure accuracy.

2. What materials do you specialize in using for metal model building, and what are their unique properties?

Metals

- Steel: Durable, strong, and resistant to corrosion, making it suitable for structural components.

- Aluminum: Lightweight, corrosion-resistant, and easy to work with, ideal for intricate details.

- Brass: Strong, ductile, and has a pleasing golden color, often used for decorative elements.

Other materials

- Plastic: Used for non-structural components, such as insulators or protective covers.

- Wood: Can be incorporated for handles, bases, or decorative accents.

3. What types of finishes can you apply to metal models, and what are the advantages and disadvantages of each?

- Polishing: Creates a smooth, reflective surface, enhancing visual appeal.

- Painting: Allows for customization with various colors and finishes (e.g., matte, glossy), but requires careful preparation and application.

- Anodizing: Electrolytic process that creates a protective oxide layer on aluminum, providing corrosion resistance and aesthetic enhancements.

- Plating: Applying a thin layer of another metal (e.g., gold, silver) for decorative or functional purposes, such as improving conductivity.

4. What software do you use for designing and prototyping metal models?

- Computer-aided design (CAD) software (e.g., SolidWorks, AutoCAD): Allows for precise modeling, simulation, and technical drawing creation.

- 3D printing software: Enables rapid prototyping and creation of complex geometries.

- CAM (computer-aided manufacturing) software: Generates toolpaths for CNC (computer numerical control) machines, automating production.

5. How do you ensure safety while working with metalworking tools and materials?

- Follow established safety protocols and wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators.

- Properly maintain and inspect tools and equipment to prevent malfunctions or accidents.

- Handle and store materials safely, avoiding sharp edges or hazardous chemicals.

- Stay aware of surroundings and potential hazards, such as moving machinery or electrical wires.

6. What quality control measures do you implement to ensure the accuracy and durability of your metal models?

- Thorough inspection and verification of dimensions using precision measuring tools.

- Non-destructive testing (e.g., ultrasonic testing, magnetic particle inspection) to detect defects or imperfections.

- Stress testing and load simulation to assess the model’s strength and durability.

- Regular calibration and maintenance of equipment to ensure accuracy.

7. Can you describe a complex metal model building project you have worked on and the challenges you faced?

- Describe the project, its complexity, and the specific challenges encountered.

- Explain how you overcame those challenges using your skills, creativity, and problem-solving abilities.

- Highlight the successful completion of the project and the lessons learned.

8. What are the current trends and advancements in metal model building, and how do you stay updated?

- Emerging technologies like 3D printing and additive manufacturing for rapid prototyping and complex designs.

- Advancements in materials science, such as lightweight and high-strength alloys.

- Increased use of automation and robotics for efficiency and precision.

- Attend industry conferences, read technical journals, and network with professionals to stay informed.

9. What sets you apart from other metal model builders in the industry?

- Emphasize your unique skills, experience, and accomplishments.

- Highlight your passion for metalworking and attention to detail.

- Explain how your knowledge and expertise can contribute to the company’s success.

10. What are your career aspirations in the field of metal model building?

- Express your desire to grow and advance in the field.

- Explain how the company’s goals align with your career aspirations.

- Show your willingness to take on new challenges and responsibilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Model Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Model Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Model Builder is responsible for constructing and repairing metal models, components, and structures. They work from blueprints or other specifications to ensure the accuracy and quality of the final product. Key job responsibilities include:

1. Constructing and Repairing Metal Models

Metal Model Builders are responsible for building and repairing metal models, components, and structures. They work from blueprints or other specifications to ensure the accuracy and quality of the final product. This may involve cutting, shaping, assembling, and welding metal materials. They may also need to repair or replace damaged metal parts.

2. Designing and Prototyping Metal Models

Metal Model Builders may be involved in designing and prototyping metal models. This involves creating conceptual designs, developing prototypes, and testing the functionality of the models. They may also need to work with engineers and other professionals to ensure that the models meet the required specifications.

3. Fabricating and Assembling Metal Components

Metal Model Builders are responsible for fabricating and assembling metal components. This involves cutting, shaping, and welding metal materials to create the desired components. They may also need to assemble the components into a finished product.

4. Testing and Inspecting Metal Models

Metal Model Builders are responsible for testing and inspecting metal models to ensure that they meet the required specifications. This may involve performing visual inspections, functional tests, and other quality control procedures.

Interview Tips

To ace an interview for a Metal Model Builder position, it is important to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the specific requirements of the position.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. For example, if you have experience in welding or metal fabrication, be sure to mention this. You can also highlight any relevant certifications or training that you have.

4. Be Enthusiastic and Positive

Throughout the interview, be enthusiastic and positive. This will show the interviewer that you are excited about the opportunity to work for the company. It will also make you more approachable and likeable.

5. Follow Up After the Interview

After the interview, be sure to follow up with a thank-you note. This will show the interviewer that you are still interested in the position and that you appreciate their time. You can also use the thank-you note to reiterate your key skills and experience.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Metal Model Builder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.