Are you gearing up for an interview for a Metal Model Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Model Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

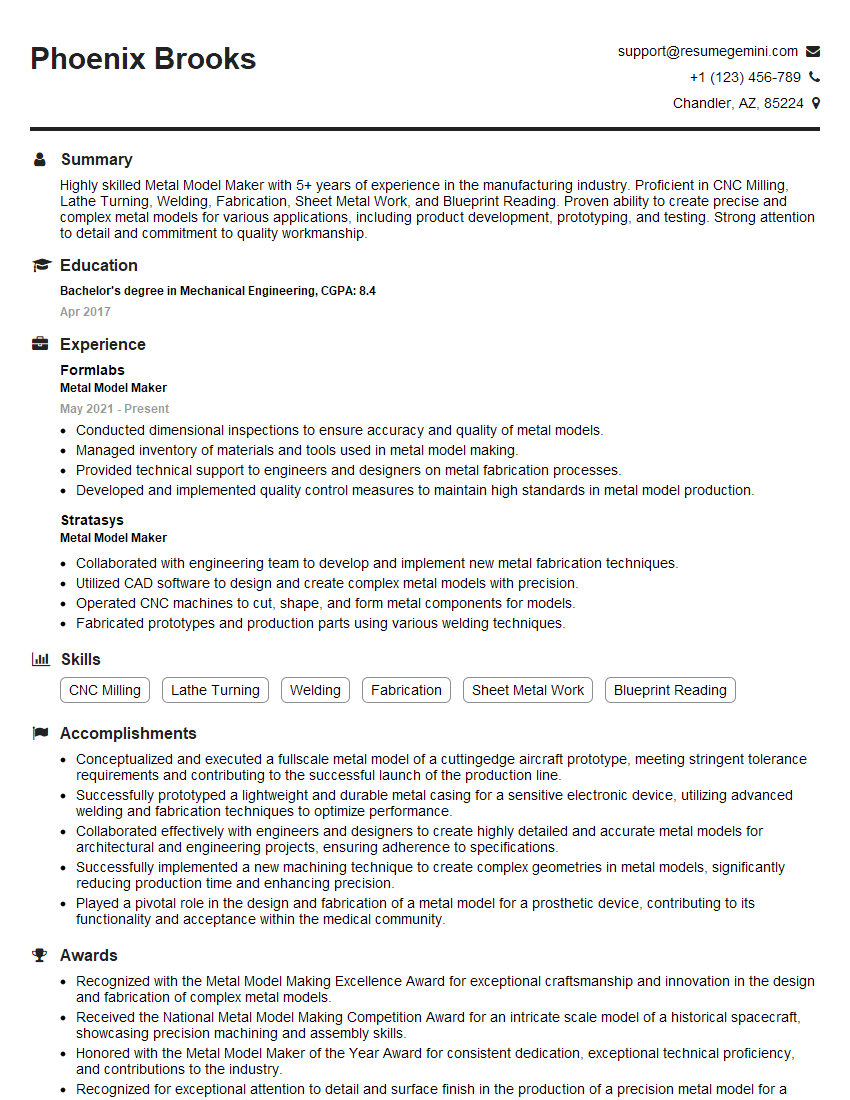

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Model Maker

1. Describe the process of creating a metal model.

– Design the model using CAD software or hand sketches. – Select the appropriate metal for the model, considering factors such as strength, durability, and corrosion resistance. – Create a mold or die for the metal casting process. – Cast the metal into the mold or die. – Remove the casting from the mold or die and clean it up. – Polish and finish the model to achieve the desired surface quality.

2. What are the different types of metal casting processes?

Sand casting

- Uses sand as the mold material.

- Relatively inexpensive and versatile.

Investment casting

- Uses a wax pattern that is invested in a ceramic mold.

- Produces high-quality castings with intricate details.

Die casting

- Uses a metal die to force molten metal into the mold.

- Produces high-volume castings with precise dimensions.

3. What are the properties of different types of metals used in model making?

– Stainless steel: Strong, durable, and corrosion-resistant. – Aluminum: Lightweight, strong, and easy to machine. – Brass: Durable, corrosion-resistant, and has a low melting point. – Zinc: Soft and easy to cast, but not as strong as other metals. – Pewter: Soft, easy to cast, and has a low melting point.

4. What are the different surface finishing techniques used for metal models?

- Polishing: Removes surface imperfections and creates a smooth, shiny finish.

- Brushing: Creates a textured surface with a matte finish.

- Patina: Creates a chemical reaction on the surface of the metal to produce a desired color or finish.

- Painting: Applies a protective or decorative coating to the metal surface.

5. What are the challenges of working with metal in model making?

- Metal is difficult to cut and shape.

- Metal can be hazardous to work with if proper precautions are not taken.

- Metal can be expensive, so it is important to use it efficiently.

- Metal can be difficult to finish to a high quality.

6. How do you ensure the accuracy and precision of metal models?

- Use precise measurement tools and techniques.

- Create accurate molds and dies.

- Use proper casting techniques.

- Inspect castings for defects and correct any errors.

7. What are the different types of metal models?

- Architectural models: Used to represent buildings and other structures.

- Automotive models: Used to represent cars, trucks, and other vehicles.

- Aircraft models: Used to represent airplanes, helicopters, and other aircraft.

- Military models: Used to represent tanks, ships, and other military equipment.

- Figurines: Used to represent people, animals, and other objects.

8. What are the applications of metal models?

- Design visualization: Used to communicate design ideas to clients and stakeholders.

- Prototyping: Used to create functional prototypes of products.

- Education: Used to teach students about engineering, design, and manufacturing.

- Collectibles: Used as decorative items or as part of a collection.

9. What are the latest trends in metal model making?

- 3D printing: Used to create complex and intricate models.

- Laser cutting: Used to cut and shape metal with precision.

- Computer-aided design (CAD): Used to design and create models digitally.

- Sustainability: Using eco-friendly materials and processes in model making.

10. What are the best practices for metal model making?

- Use the right tools and materials for the job.

- Follow safety precautions when working with metal.

- Be patient and take your time.

- Seek feedback from experienced model makers.

- Continuously improve your skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Model Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Model Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Metal Model Makers are skilled professionals who create physical models of metal components using a variety of techniques. They may work with a variety of metals, including steel, aluminum, and bronze. Their key job responsibilities include:

1. Fabricating metal components

Metal Model Makers use a variety of tools and techniques to fabricate metal components. These components may be used for a variety of purposes, such as prototyping new products, creating molds for casting, or repairing damaged parts.

- Cutting and shaping metal using a variety of tools, such as saws, shears, and grinders

- Welding or brazing metal components together

- Casting metal components using a variety of techniques, such as sand casting, investment casting, and die casting

2. Finishing metal components

Once metal components have been fabricated, they must be finished to give them a smooth surface and to protect them from corrosion. Finishing processes may include:

- Sanding and polishing metal components

- Plating metal components with a variety of materials, such as chrome, nickel, or gold

- Painting or powder coating metal components

3. Inspecting metal components

Metal Model Makers must inspect metal components to ensure that they meet quality standards. This may involve measuring components to ensure that they are the correct size and shape, and checking for defects such as cracks, voids, or inclusions.

- Using a variety of inspection tools and techniques, such as calipers, micrometers, and gauges

- Documenting inspection results and reporting any defects found

4. Maintaining equipment

Metal Model Makers must maintain their equipment in good working order. This may involve cleaning and lubricating equipment, and performing minor repairs.

- Following manufacturer’s instructions for equipment maintenance

- Identifying and resolving equipment problems

Interview Tips

Preparing for an interview for a Metal Model Maker position can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you answer questions intelligently and show the interviewer that you’re genuinely interested in the opportunity.

- Visit the company’s website and read the company’s mission statement, values, and history.

- Read the job description for the Metal Model Maker position.

- Look for news articles or other information about the company and the industry.

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in front of a mirror or with a friend or family member.

- Prepare a brief introduction of yourself, including your skills, experience, and why you’re interested in the position.

- Think about why you’re interested in the specific company and position you’re applying for.

- Practice answering questions about your experience and skills.

3. Bring a portfolio of your work

If you have any examples of your work, bring it along to your interview. This could include photos of your metal models, drawings, or other examples of your skills.

- Include a variety of examples of your work, including different types of metal models and finishing techniques.

- Be prepared to talk about your work and explain how it demonstrates your skills and experience.

- If you don’t have any physical examples of your work, bring a digital portfolio or website that showcases your skills.

4. Dress professionally and be on time

First impressions matter, so it’s important to dress appropriately and arrive on time for your interview. This shows the interviewer that you’re professional and respectful of their time.

- Wear a suit or other business-appropriate attire.

- Be on time for your interview. If you’re running late, call or email the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Metal Model Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!