Are you gearing up for an interview for a Metal Mold Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Metal Mold Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

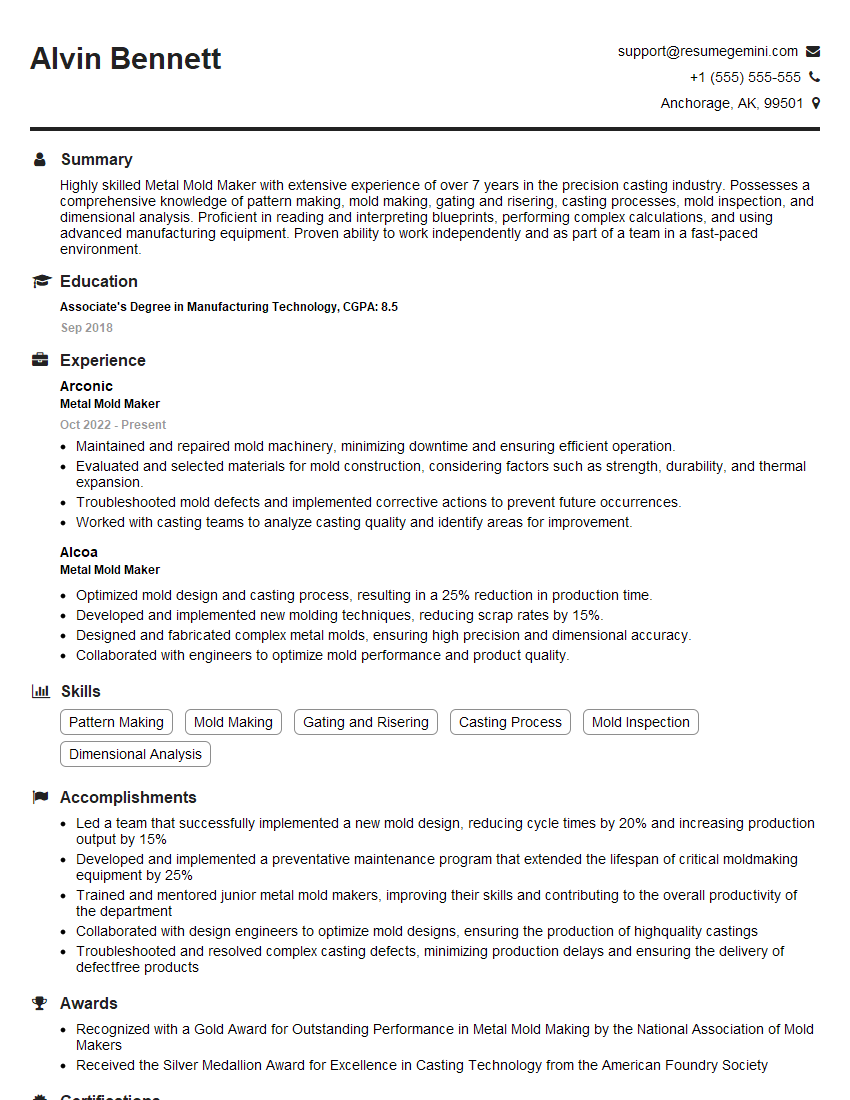

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Metal Mold Maker

1. What are the different types of metal molds and their applications?

There are various types of metal molds, each with specific applications.

- Gravity Die Casting Molds: Used for producing complex parts with intricate shapes, suitable for low to medium production volumes.

- Pressure Die Casting Molds: Designed for high-volume production of intricate parts with high dimensional accuracy and surface finish.

- Injection Molding Molds: Used for creating plastic components, but can also be adapted for metal casting.

- Investment Casting Molds: Allow for the production of complex parts with intricate details, often used for aerospace and medical applications.

- Sand Casting Molds: Traditional method for producing large, one-of-a-kind parts, suitable for low-volume applications.

2. Explain the process of creating a metal mold from design to production.

Design and Engineering

- Create a 3D CAD model of the desired part.

- Design the mold components, including the cavity, cores, and gating system.

Mold Manufacturing

- Machine the mold components using CNC or EDM.

- Assemble the mold components and ensure proper alignment.

- Perform mold testing and make necessary adjustments.

Production

- Set up the mold in the casting machine.

- Pour molten metal into the mold.

- Allow the metal to solidify and cool.

- Eject the finished part from the mold.

3. What are the key factors to consider when designing a metal mold?

When designing a metal mold, several key factors need to be considered:

- Part Design: The complexity of the part, draft angles, and dimensional tolerances.

- Casting Process: The specific casting method and its requirements.

- Material Properties: The thermal and mechanical properties of the metal being cast.

- Mold Life: The number of castings expected from the mold before replacement.

- Cost and Production Time: Balancing the cost of mold production with the desired production rate.

4. How do you determine the appropriate materials for mold construction?

The choice of materials for mold construction depends on several factors:

- Casting Temperature: The temperature of the molten metal during casting.

- Thermal Conductivity: The ability of the mold material to transfer heat from the molten metal.

- Strength and Durability: The mold’s ability to withstand the forces and wear associated with casting.

- Cost-Effectiveness: The overall cost of the mold material and its compatibility with the casting process.

5. What techniques are used to improve the efficiency and quality of metal castings?

- Mold Cooling: Using water or air to cool the mold during casting, which reduces cycle time and improves casting quality.

- Gating System Optimization: Designing the mold’s gating system to ensure proper metal flow, minimize turbulence, and reduce defects.

- Mold Release Agents: Applying coatings to the mold to prevent the casting from sticking and facilitate ejection.

- Vacuum Casting: Using a vacuum to draw the molten metal into the mold, which improves casting quality and reduces porosity.

- Post-Processing: Performing operations such as heat treatment, machining, or surface finishing to enhance the properties of the finished castings.

6. What are the common defects that can occur in metal castings, and how can they be prevented?

Common defects in metal castings include:

- Porosity: Air bubbles trapped in the casting due to improper mold design or pouring practices.

- Shrinkage: Cavities or voids caused by the metal contracting as it cools.

- Cold Shots: Incomplete filling of the mold due to insufficient molten metal.

- Cracks: Fractures in the casting due to thermal stresses or casting defects.

- Inclusions: Foreign materials trapped in the casting, affecting its properties.

- Preventive measures: Proper mold design, optimized gating system, degassing of molten metal, controlled cooling, and proper handling can prevent these defects.

7. Describe the different maintenance practices for metal molds.

- Regular Cleaning: Removing debris, metal chips, and contaminants from the mold surfaces.

- Inspection and Repair: Regularly checking for wear, damage, or cracks and making necessary repairs.

- Lubrication: Applying lubricants to moving parts to reduce friction and wear.

- Temperature Monitoring: Using thermocouples or infrared thermometers to monitor mold temperature and adjust cooling systems accordingly.

- Preventive Maintenance: Regularly performing scheduled maintenance tasks to identify and address potential issues before they cause major failures.

8. What are the latest advancements in metal mold manufacturing technology?

- Additive Manufacturing (3D Printing): Creating molds directly from digital models, allowing for complex designs and faster production.

- High-Speed Machining: Using advanced cutting tools and CNC machines to machine molds with high precision and reduced cycle times.

- Simulation Software: Using computer-aided engineering (CAE) software to simulate mold performance and optimize design.

- Automation and Robotics: Integrating robots and automated systems to improve mold manufacturing efficiency and consistency.

9. What are the key safety considerations when working with metal molds?

- Proper Personal Protective Equipment (PPE): Wearing safety glasses, gloves, and protective clothing to prevent injuries from hot metal, sparks, or debris.

- Safe Handling of Molten Metal: Following proper pouring procedures and using appropriate protective barriers.

- Mold Maintenance and Inspection: Regularly inspecting molds for damage or wear and ensuring proper maintenance to prevent accidents.

- Ventilation and Fume Extraction: Ensuring adequate ventilation and fume extraction systems to remove hazardous fumes and gases from the work area.

- Training and Education: Providing thorough training to employees on safe mold handling, casting procedures, and emergency response protocols.

10. What are your strengths and weaknesses as a Metal Mold Maker?

Strengths:

- Proficient in metal mold design, manufacturing, and maintenance.

- Expertise in various casting processes, including gravity, pressure, and investment casting.

- Strong understanding of mold materials, properties, and selection.

- Skilled in using CNC machines, EDM, and other mold manufacturing equipment.

- Excellent problem-solving and analytical abilities.

Weaknesses:

- Limited experience with certain specialized casting techniques, such as vacuum casting.

- Still developing knowledge in advanced mold simulation software.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Metal Mold Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Metal Mold Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Metal Mold Maker is responsible for designing, creating, and maintaining molds used in the production of metal parts. This role requires a high level of precision, attention to detail, and knowledge of metalworking techniques.

1. Mold Design and Creation

Collaborate with engineers and designers to develop mold designs.

- Select appropriate materials and tooling for mold construction.

- Utilize computer-aided design (CAD) software to create detailed mold drawings.

2. Mold Fabrication

Fabricate molds using various metalworking techniques, such as machining, welding, and grinding.

- Operate CNC machines, mills, and lathes to create mold components.

- Ensure dimensional accuracy and surface finish meet specifications.

3. Mold Maintenance and Repair

Maintain and repair molds to ensure their longevity and optimal performance.

- Inspect molds for wear and damage.

- Repair or replace damaged mold components.

4. Quality Control

Ensure the quality of molds and the parts produced using them.

- Conduct inspections and testing to verify mold dimensions and functionality.

- Identify and resolve any quality issues.

Interview Tips

Interview preparation is essential for showcasing your skills and experience as a Metal Mold Maker. Follow these tips to ace your interview:

1. Research the Company and Position

Thoroughly research the company, its products or services, and the specific role you’re applying for. This knowledge will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website, read their annual reports, and check their social media presence.

- Identify the key responsibilities and skills required for the position.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the interview.

- Research common interview questions for Metal Mold Makers.

- Prepare brief and concise answers that highlight your relevant skills and experience.

3. Showcase Your Skills and Experience

Use the STAR (Situation, Task, Action, Result) method to describe your accomplishments and highlight your problem-solving abilities.

- Provide specific examples of your work, quantifying your results whenever possible.

- Discuss projects or tasks that demonstrate your technical skills in mold design, fabrication, maintenance, and quality control.

4. Be Prepared with Questions

Ask thoughtful questions at the end of the interview to show your interest and engagement. This also gives you an opportunity to clarify any aspects of the role or company.

- Prepare questions about the company’s mold-making capabilities, upcoming projects, and growth opportunities.

- Ask about the team culture and training opportunities.

Next Step:

Now that you’re armed with the knowledge of Metal Mold Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Metal Mold Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini